Maintaining outdoor machinery is crucial for ensuring its longevity and optimal performance. Proper knowledge of the components that make up your equipment will help you troubleshoot, repair, and replace parts as needed. Having access to detailed visuals and breakdowns of each section allows you to easily identify individual elements, simplifying the repair process and saving you both time and money.

Whether you’re a seasoned gardener or just starting out with your equipment, understanding how everything works together will help you take care of your tools more efficiently. Visual aids are invaluable for identifying the right pieces when it comes to repairs, so you can tackle any issues confidently and avoid unnecessary mistakes.

Understanding the John Deere 737 Mower

Having a solid understanding of your equipment is essential for its care and maintenance. Lawn care tools are designed with several key elements that work in unison to provide a smooth and efficient experience. Recognizing the components that contribute to the functionality of your machine allows you to properly maintain it, ensuring its performance is consistently at its best.

Key Features of the Machine

This particular outdoor tool is equipped with innovative features that make it a popular choice for users who need precision and durability. The engine system provides enough power for efficient grass cutting, while the maneuvering system allows for easy handling around obstacles. A well-maintained unit offers high efficiency and precision in managing large areas of grass with ease.

Importance of Regular Maintenance

Like all complex machinery, keeping the equipment in top shape requires regular checks and maintenance. Ensuring that all moving parts are lubricated, replacing worn-out components, and cleaning the system can significantly extend its lifespan. By paying attention to the details and understanding the core elements, users can avoid costly repairs and enhance the machine’s performance.

Identifying Key Components and Parts

Recognizing the main components of your outdoor equipment is essential for proper maintenance and efficient operation. Understanding how each part functions together ensures smooth performance and allows you to quickly diagnose any issues that may arise. By knowing the essential elements, you can more easily maintain and repair the tool when necessary.

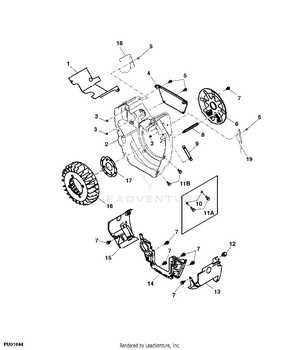

Engine and Power Systems

The engine is the heart of the machine, providing the power necessary for cutting and maneuvering. It is essential to check the engine for any wear and tear, as well as ensure proper fuel and air flow. A well-functioning power system contributes to smooth operation, reducing the chances of unexpected breakdowns.

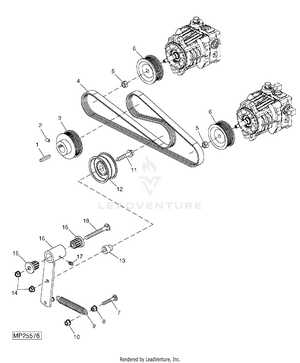

Transmission and Control Systems

The transmission system controls the movement and speed of the equipment. Regularly inspecting the belts, pulleys, and hydraulic lines helps avoid potential malfunctions. The control mechanisms, including levers and pedals, allow for precise movements, making it important to keep them properly adjusted for ease of operation.

How to Use the Parts Diagram Effectively

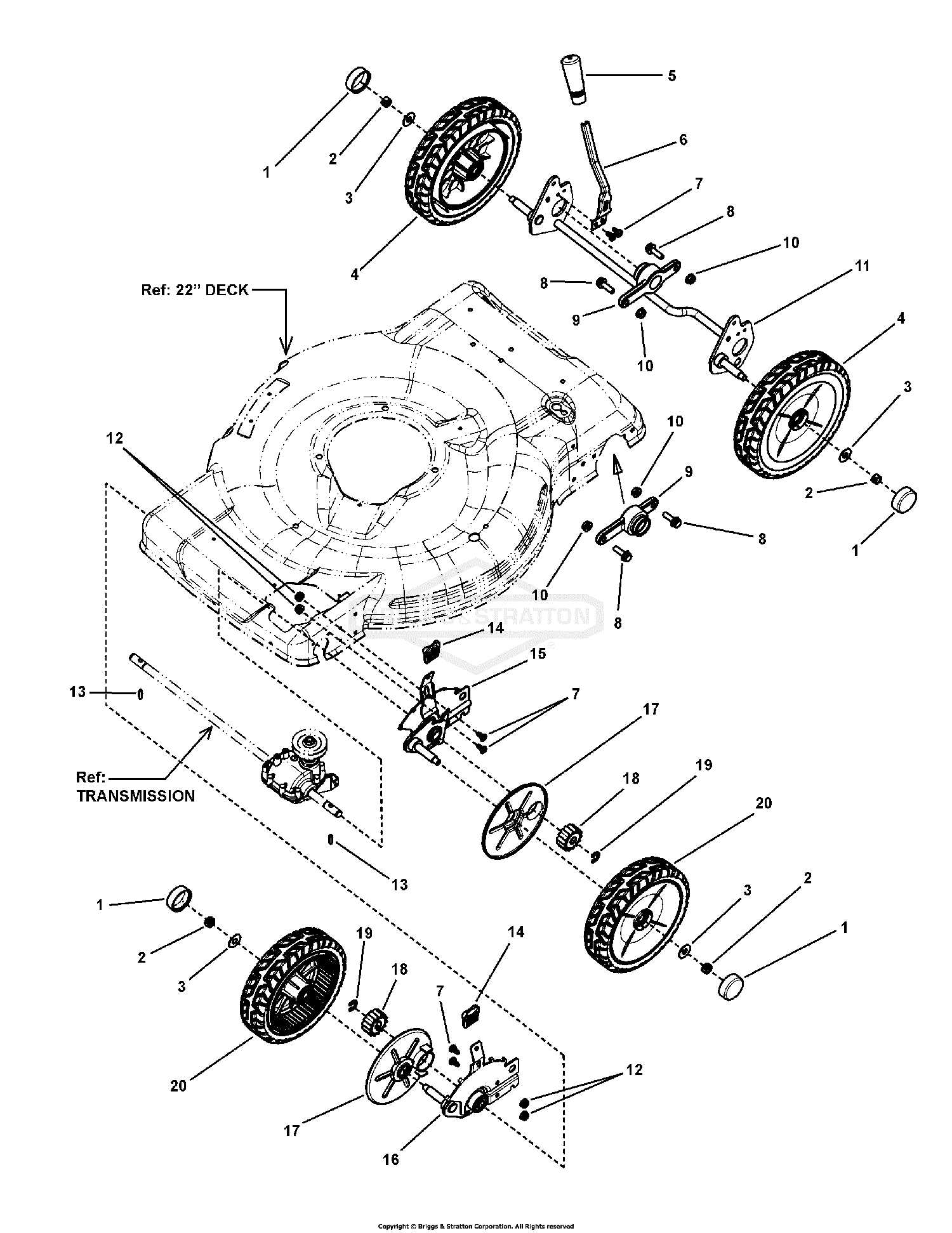

Using a detailed visual reference of your equipment’s components can greatly simplify maintenance and repairs. With a clear illustration of all elements, it becomes easier to identify worn-out or damaged sections, allowing you to replace or repair them quickly. Understanding how to interpret these visual aids can save time and effort in keeping your equipment running smoothly.

Step-by-Step Identification Process

Start by focusing on the major components and how they are connected. Each section of the guide will typically feature labeled parts with corresponding numbers. By matching the labels to the corresponding parts in your machine, you can quickly pinpoint where any issues might lie. Take your time to familiarize yourself with each section before making any adjustments.

Maintaining Accuracy During Repairs

Once you’ve identified the necessary components, double-check the specifics of the part to ensure you’re using the correct replacement. Having the right part on hand before you begin repairs reduces the risk of interruptions and errors. Being thorough in this process will help maintain the efficiency and durability of your equipment in the long term.