Maintaining your machinery requires a clear understanding of its components and how they interact. A comprehensive visual guide is essential for any owner, ensuring that you can quickly identify, repair, or replace parts when needed.

Knowing the layout and structure of your machine is key to efficient maintenance and troubleshooting. With the right resources, even complex issues become easier to address. By familiarizing yourself with a detailed visual guide, you can enhance your equipment’s longevity and performance.

Whether you are a seasoned mechanic or a first-time owner, having access to a reliable reference can save time and reduce costly mistakes. Understanding how to interpret the schematic will empower you to handle a range of repairs with confidence.

Understanding the 8N Ford Tractor Parts

When it comes to maintaining your equipment, a deep understanding of its components is crucial. The more familiar you become with how each element functions, the easier it will be to identify issues and perform necessary repairs. By breaking down the main components, you gain a clearer picture of how everything fits together.

Main Mechanical Components

The engine and transmission are the heart of any machine. They work in unison to provide power and movement. Other vital systems, such as the cooling, electrical, and fuel systems, all play integral roles in ensuring smooth operation. Understanding the purpose of each section will help you maintain optimal performance and avoid unnecessary breakdowns.

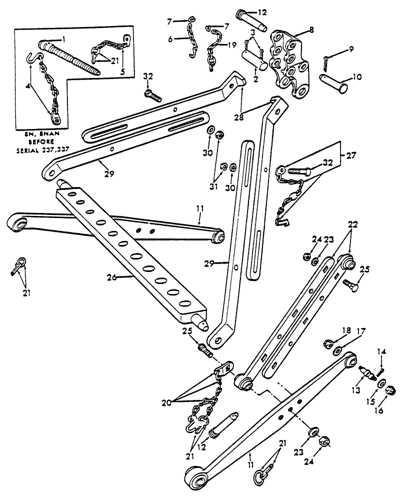

Structural and Support Elements

Supporting elements, including the frame, axles, and wheels, provide stability and enable smooth handling on various terrains. Recognizing the importance of these structures allows for better decision-making when it comes to repairs and replacements. Regular inspection of these components will help keep your equipment working at its best for longer periods.

How to Read an 8N Ford Diagram

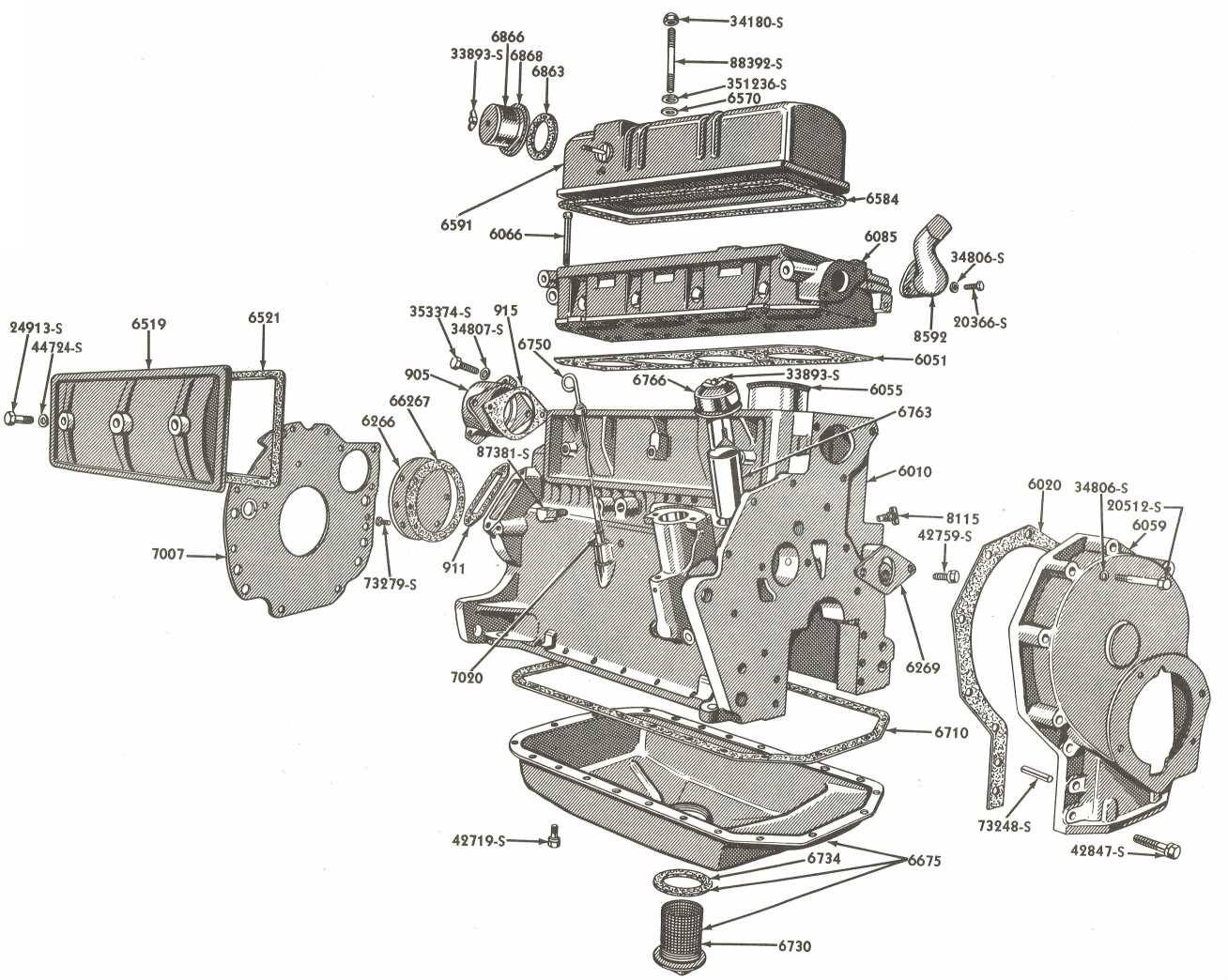

Understanding how to interpret visual guides is essential for effective maintenance and repair. These guides provide a clear, organized way to identify each part and its function within the system. By knowing how to read these resources, you can quickly find the necessary components and ensure everything is in working order.

Identifying Key Symbols and Labels

Each component is represented by a unique symbol or label. Understanding these symbols is the first step to navigating any guide. Often, these diagrams will use simplified representations to make identification easier, with numbers or letters corresponding to specific parts within the machine. Familiarizing yourself with these symbols will make it simpler to locate parts when troubleshooting or repairing.

Following the Flow of Systems

Diagrams are also organized to reflect the flow of different systems. For example, fuel or electrical systems are often shown in a sequential manner to illustrate how energy or fluids move through the machine. By following these flow lines, you can better understand how different components interact and how a malfunction in one area could affect others.

Essential Parts for Tractor Maintenance

Proper upkeep of your machine depends on maintaining its key components. Some elements are more crucial than others for ensuring optimal performance and preventing breakdowns. Regular inspection and timely replacement of these critical sections can extend the life of the equipment and reduce downtime.

Engine and Fuel System

The engine is the core of any machinery, providing the power needed for operation. Similarly, the fuel system is essential for delivering the necessary energy. Ensuring that these systems are clean and functioning smoothly is key to avoiding major failures. Regular oil changes, filter replacements, and fuel checks help maintain these systems in peak condition.

Cooling and Electrical Systems

Overheating can lead to significant damage if the cooling system isn’t working efficiently. It’s essential to keep coolant levels in check and inspect hoses for wear. The electrical system, which powers the lights, ignition, and other systems, also requires routine checks. A malfunctioning alternator or worn-out wires can result in unexpected shutdowns.