In construction and heavy machinery, efficient tools play a significant role in maximizing productivity. The seamless connection of attachments to the main unit is essential for smooth operation, and understanding how these components interact is crucial for proper maintenance and functionality.

Each machine is designed with a specific system that allows for easy installation and removal of various implements. By reviewing the key elements of these systems, operators and technicians can ensure that all pieces are functioning correctly and safely.

In this guide, we will explore the essential components involved in the connection process. By understanding their design and layout, users can better manage their equipment and troubleshoot potential issues more effectively. Whether you’re a seasoned technician or a new operator, this knowledge is vital for maintaining your machine’s performance and longevity.

Understanding Bobcat Quick Attach System

In modern machinery, the ability to swiftly connect and disconnect implements is key to maximizing efficiency. The system that facilitates this function involves several critical elements, each designed to ensure smooth operation and secure attachment. A deep understanding of these components helps operators improve their workflow and troubleshoot issues as they arise.

These systems are built to offer flexibility and speed, allowing users to switch tools without unnecessary downtime. By understanding how each part contributes to the overall mechanism, one can ensure the equipment remains in optimal working condition, reducing the risk of damage or wear over time.

The connection process itself involves several components, including locking mechanisms, frame attachments, and safety features. Each part plays a role in ensuring that the attachment is securely fixed while remaining easy to disengage when necessary. Familiarity with this system can enhance safety, performance, and the overall lifespan of the equipment.

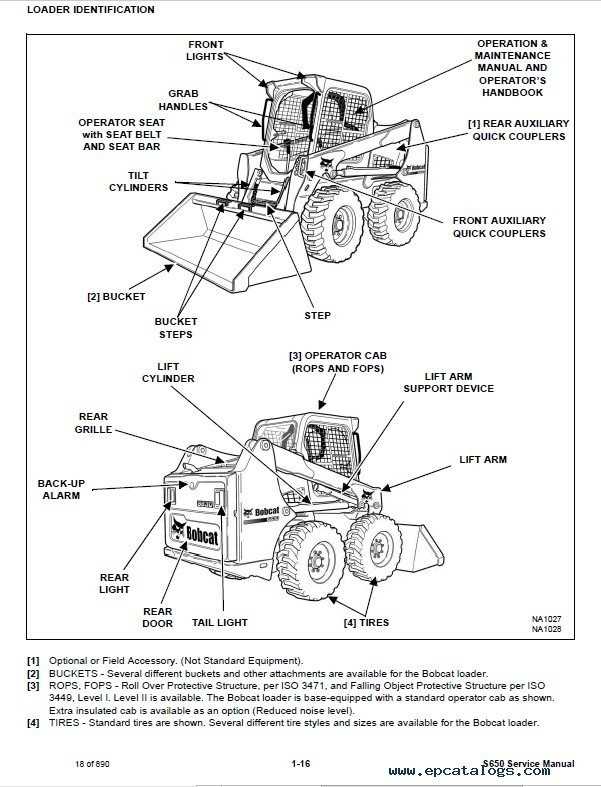

Identifying Key Components in the Diagram

When examining a connection system for heavy machinery, it is essential to recognize the various elements that contribute to its operation. A clear understanding of each component helps ensure the system functions effectively and is maintained properly. By studying these critical parts, users can troubleshoot, repair, and replace components when necessary.

Locking Mechanism and Safety Features

The locking mechanism is one of the most crucial elements in the connection process. This feature ensures that implements remain securely attached during operation. Understanding how this system functions, including the safety locks and release systems, is vital for preventing accidents and ensuring proper attachment.

Frame and Mounting Connections

The frame and mounting connections are responsible for providing a stable base for the implements. These components allow for a secure fit between the machine and attachment, ensuring that the equipment operates smoothly and efficiently. Proper inspection and maintenance of these elements are necessary to avoid wear or misalignment, which could affect performance.

How to Use the Bobcat Quick Attach Parts

Operating a machinery connection system efficiently requires an understanding of how each element functions together. Knowing the correct procedure for securing and releasing attachments ensures smooth operation, minimizes downtime, and extends the lifespan of both the machine and its accessories. Familiarizing yourself with the steps involved is essential for maximizing productivity and safety.

First, ensure the system is properly aligned before attempting to connect any implement. Carefully follow the manufacturer’s instructions for locking mechanisms and verify that each component is in place. Once securely attached, test the connection by performing light movements to ensure everything is functioning as expected.

When disconnecting, always engage the release system slowly and carefully, making sure all safety features are intact. This prevents unnecessary damage to the components and maintains the integrity of the machinery. Regular maintenance and proper use of these systems will help prevent issues and keep the equipment running at peak performance.