Maintaining and operating large machinery requires a deep understanding of its various components. Whether it’s for routine maintenance or troubleshooting, knowing the specific parts of equipment is essential for smooth and efficient performance. This knowledge allows for quicker repairs, more effective usage, and overall enhanced longevity of the machine.

In this guide, we will explore the key elements of agricultural tools, offering insights into their structure and function. Recognizing each piece’s role can help users become more proficient with their equipment, ultimately improving both productivity and safety.

Effective understanding of machinery involves familiarity with its individual parts. With this knowledge, operators can quickly identify any issues and address them before they become serious problems. This guide will simplify this process, making it easier for anyone to identify and maintain the crucial elements of their agricultural equipment.

Understanding Agricultural Equipment Components and Functions

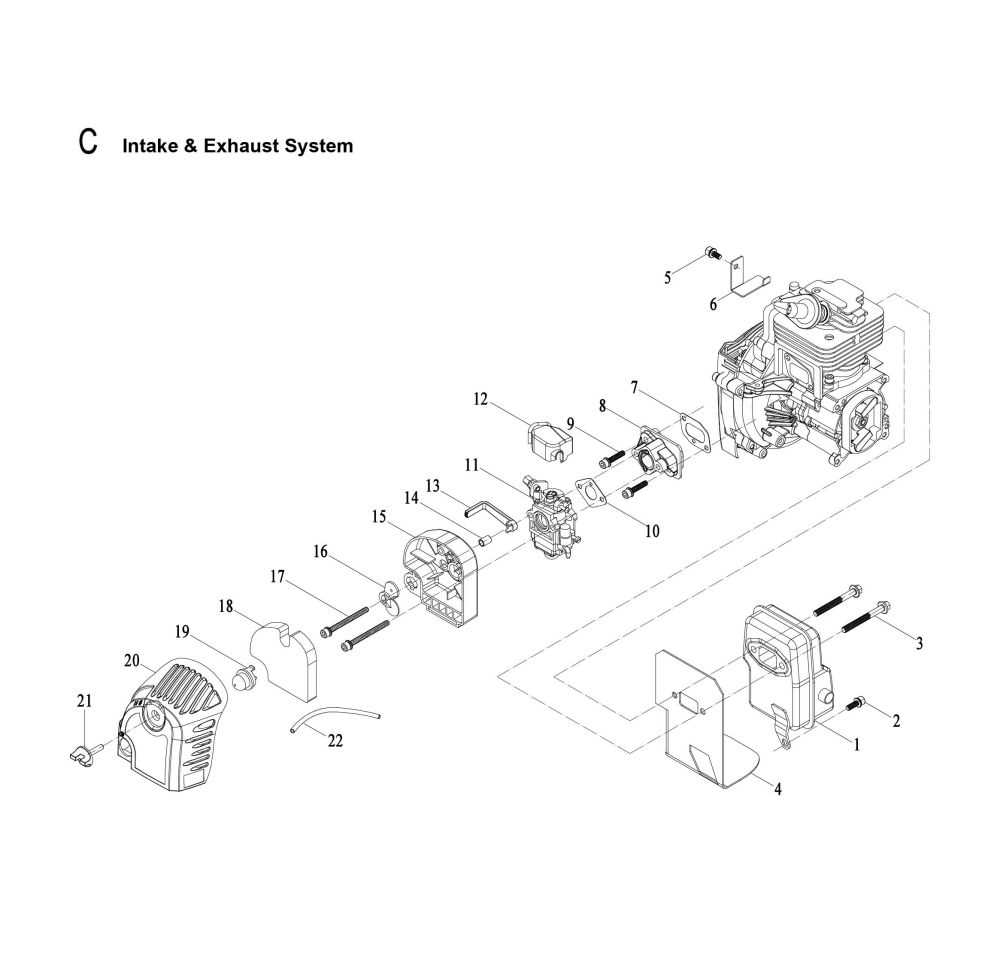

To operate machinery effectively, it’s important to recognize the various elements that make up the equipment. Each component serves a specific purpose, contributing to the overall efficiency and functionality of the machine. Knowing how these individual pieces work together is essential for both maintenance and proper use.

The key to successful operation lies in understanding the role each part plays. Whether it’s the motor, the cutting mechanism, or the frame, every element is designed to fulfill a distinct function. Familiarity with these components allows for easier troubleshooting, more efficient use, and the ability to address potential issues before they escalate.

Recognizing the functions of the different parts is crucial for any operator. For example, certain sections of the equipment are designed to handle specific tasks such as cutting, adjusting, or stabilizing, while others may be focused on power transmission or control. By gaining a deeper understanding of each function, users can enhance the performance and longevity of their machinery.

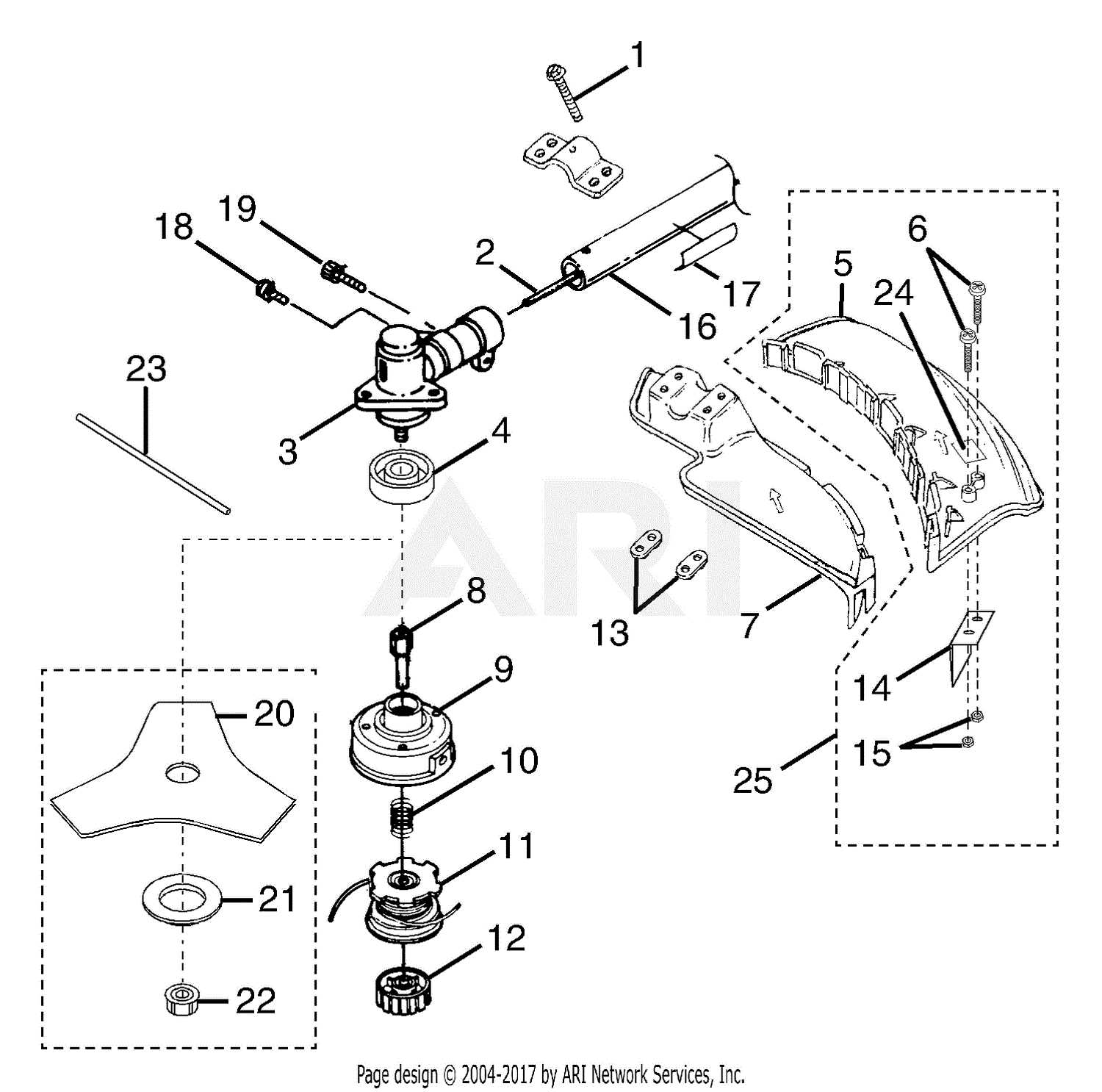

Essential Components of a Brush Hog

Every piece of machinery designed for heavy-duty fieldwork consists of several crucial elements that work together to ensure smooth operation. These components are engineered to handle demanding tasks, and understanding their function is key to using the machine effectively. Each section plays an integral role in the overall performance and efficiency.

The core structure of such equipment includes the drive mechanism, cutting elements, and support frame. These elements work in tandem to provide power, stability, and precision when tackling large areas of dense vegetation. By understanding how each component functions within the system, operators can more easily maintain and repair their equipment, keeping it in top condition.

Key elements like the rotating blades, power transmission system, and adjustable frame provide versatility and control. When properly maintained, these components allow the machine to perform a wide variety of tasks, from clearing overgrown land to managing difficult terrain. Identifying these pieces and knowing their functions ensures that operators can make informed decisions about usage and upkeep.

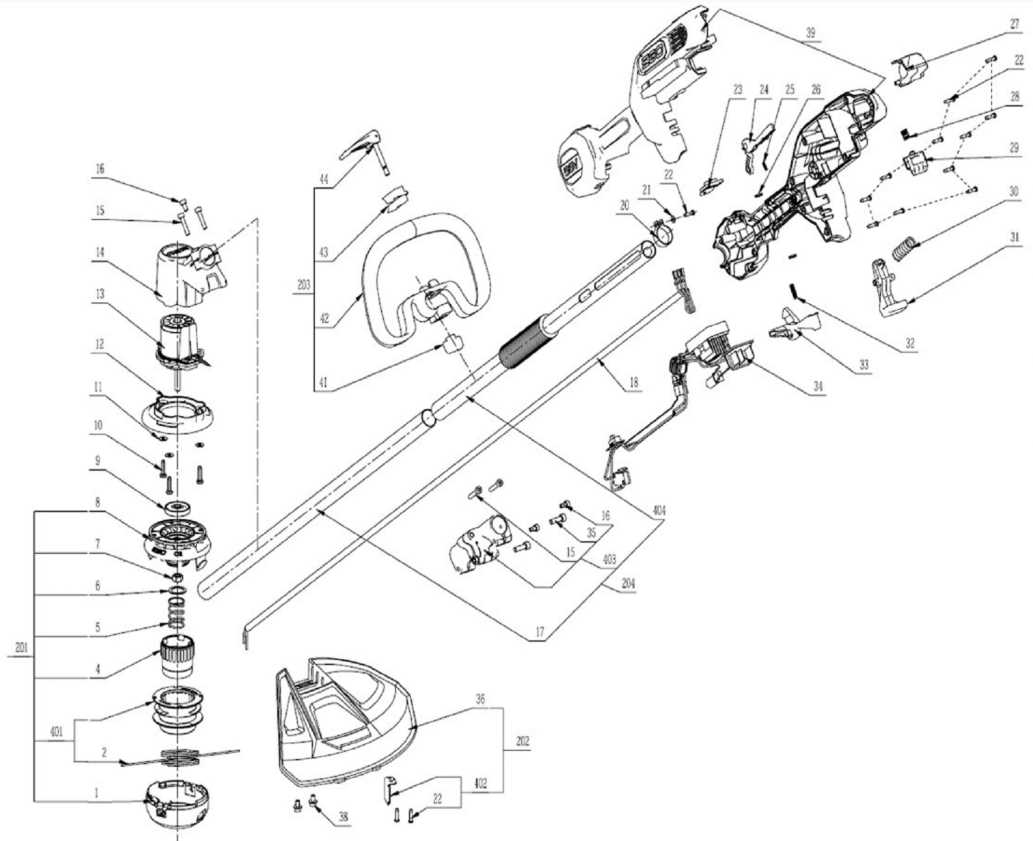

How to Use the Parts Diagram Effectively

Using a detailed visual guide to understand the components of your equipment can significantly enhance your ability to troubleshoot, repair, and maintain it. This reference helps operators quickly identify each section, understand its function, and spot any potential issues. By knowing where to look, you can save time and avoid unnecessary complications.

Step-by-Step Navigation

The first step in using such a guide effectively is familiarizing yourself with the layout. Each section of the visual representation is usually labeled, making it easier to trace specific elements. Follow the guide from top to bottom or in sections, focusing on one part at a time to avoid confusion.

Quick Troubleshooting and Maintenance

When a problem arises, the visual guide can be invaluable for diagnosing issues. By comparing the equipment’s actual setup with the diagram, you can identify missing or damaged components. Regularly referencing the diagram during maintenance tasks ensures that no part is overlooked and everything is functioning as it should.