When maintaining or repairing complex machinery, a clear understanding of its individual components and how they interact is essential. A visual reference can significantly aid in this process, providing clarity and making the task more manageable. Knowing each part’s function and placement allows for efficient troubleshooting and part replacement.

For anyone working with heavy-duty equipment, having access to a comprehensive map of its core elements is invaluable. It helps ensure that all pieces are properly aligned and functioning. Identifying wear or damage early on can save time and resources, preventing costly mistakes during maintenance procedures.

Understanding these components is not only beneficial for proper upkeep but also crucial for troubleshooting common problems. Whether you are repairing or performing routine checks, having a thorough guide can simplify the process and improve overall efficiency.

Maintaining and repairing outdoor machinery requires a solid understanding of its key components. By familiarizing yourself with the internal structure and assembly, you can easily identify issues and perform necessary repairs. This guide will help you navigate through the essential parts of the equipment, providing you with the knowledge to handle it effectively.

Accurate identification of each piece is crucial for efficient functioning. Without proper awareness, problems can go unnoticed, potentially leading to equipment failure. Whether you’re troubleshooting or upgrading, knowing how each component fits together ensures smooth operation and longevity.

With the right visual reference and understanding, any operator can confidently handle repair tasks, ensuring the machine continues to work at peak performance. This section offers insights on how to interpret these references for more informed decision-making and smoother maintenance processes.

Key Components of the Machine

In any robust mechanical setup, several critical elements contribute to its effective functioning. Understanding how these components work together allows for better management, troubleshooting, and maintenance. Each part has a specific role, and when all the parts are in harmony, the machine operates at peak efficiency. Knowing these components and their functions ensures that the equipment continues to work smoothly for extended periods.

Some of the most vital components include the engine, which powers the entire system, and the hydraulic system, responsible for generating the force required for operation. Additionally, the frame acts as the foundation, providing structural integrity, while smaller yet equally important elements like belts and pulleys help transmit power throughout the machine. Familiarizing yourself with these parts helps in understanding potential issues and performing effective repairs.

How to Read a Machine Illustration

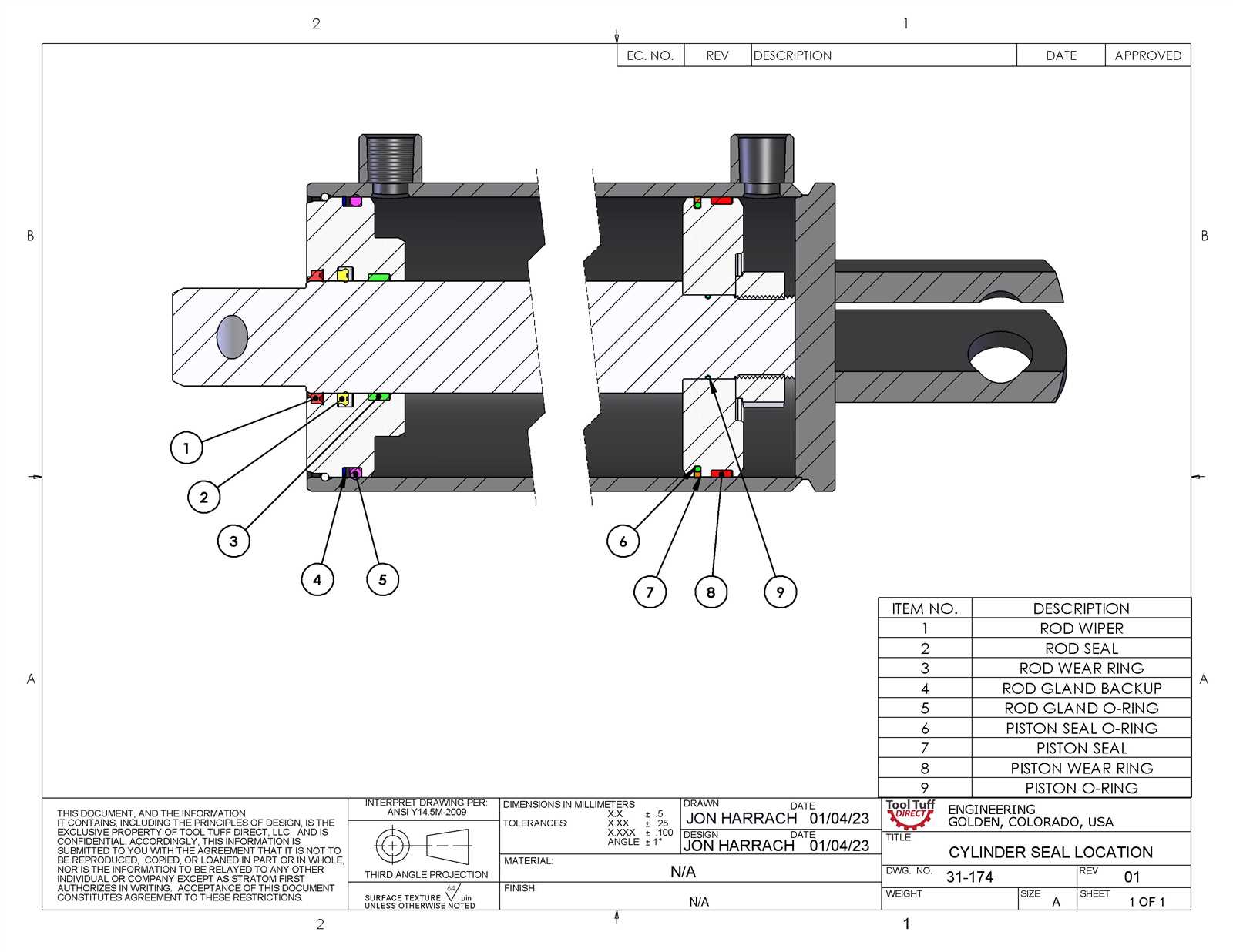

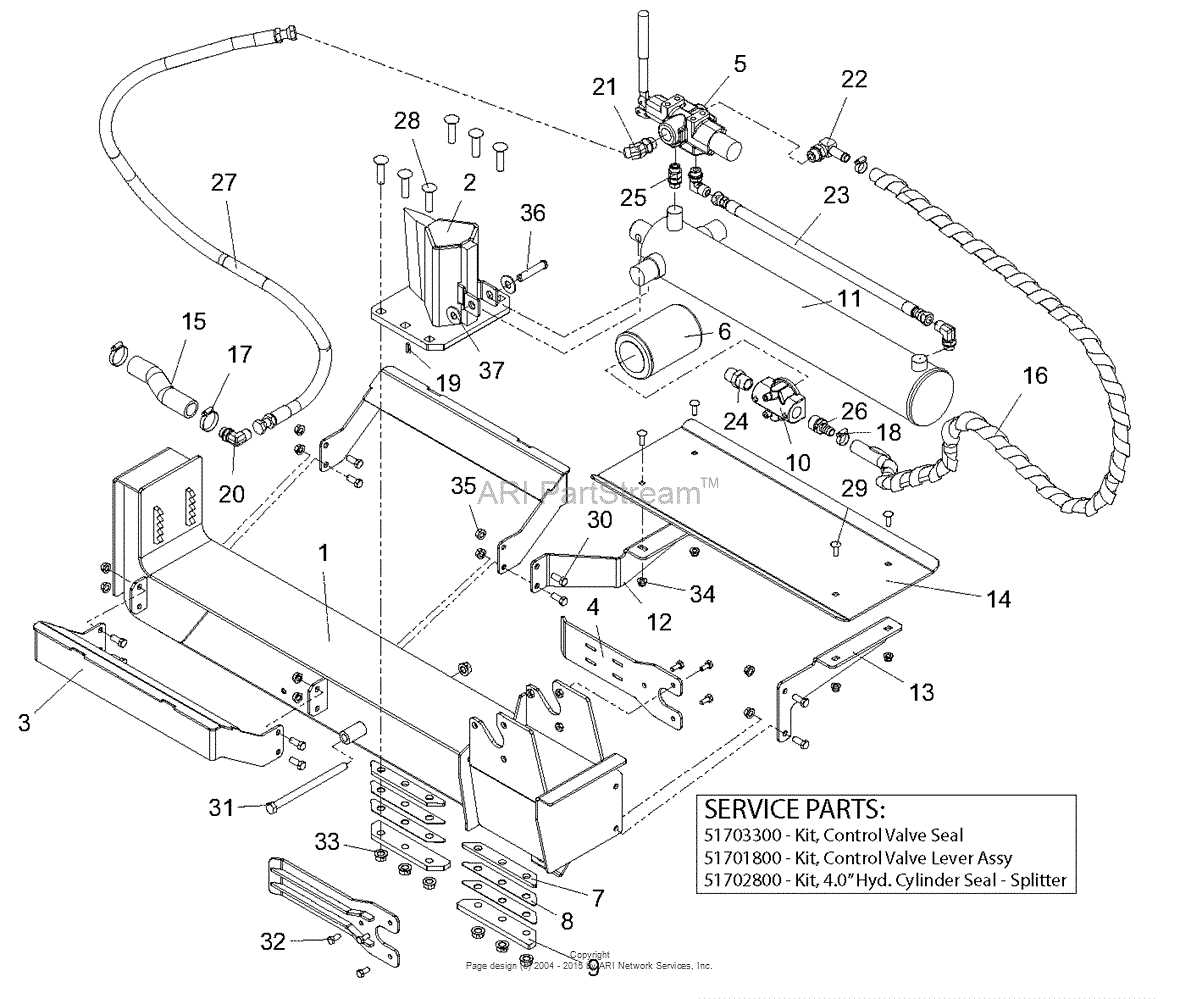

Understanding a machine’s technical illustration is essential for effective maintenance and repairs. These illustrations offer a clear view of how the components are arranged and connected, allowing users to quickly identify each part’s function and location. Reading them properly enables efficient troubleshooting, part replacement, and regular maintenance without unnecessary confusion.

The key to interpreting such a drawing lies in recognizing the symbols, lines, and labels that correspond to each component. Each part is typically numbered or named, making it easier to locate specific elements. Additionally, arrows or lines may show how the parts are interconnected, while a parts list provides additional details on specifications or replacement options. Familiarizing yourself with these elements helps ensure you’re equipped to handle any maintenance task with confidence.

Common Issues and Solutions for Machines

When operating heavy-duty equipment, it’s normal to encounter occasional issues that may disrupt performance. Identifying these problems early and knowing how to address them can save time and money. By understanding common challenges and their solutions, users can maintain the equipment effectively and avoid costly repairs.

Frequent Problems

Several issues commonly arise during regular use. These problems can range from mechanical failures to wear and tear of specific components. Below are some of the most frequently encountered difficulties:

- Loss of power – This can be caused by engine malfunctions or fuel delivery problems.

- Hydraulic failure – Common in systems where fluid levels are low or seals are damaged.

- Excessive noise – Often due to loose components or friction in the moving parts.

- Inconsistent operation – This may be caused by faulty electrical connections or improper maintenance.

Solutions for Effective Maintenance

Addressing these issues requires proper troubleshooting and a few simple maintenance steps. Here’s how to resolve some of the most common problems:

- Check fluid levels – Ensure the hydraulic fluid is at the correct level and that there are no leaks in the system.

- Inspect the engine – Regularly examine the engine for fuel issues, air filters, and spark plugs.

- Tighten loose components – Ensure all bolts, nuts, and screws are tightened to prevent unnecessary movement.

- Clean regularly – Keep the machine clean and free of debris, as this can improve performance and reduce wear.