When it comes to maintaining outdoor machinery, understanding the various elements that make up the machine is crucial. A clear representation of these components can significantly simplify repair and maintenance tasks, helping you to keep your device running smoothly for longer periods. Recognizing each part’s role ensures you know exactly where to focus when troubleshooting or replacing any malfunctioning elements.

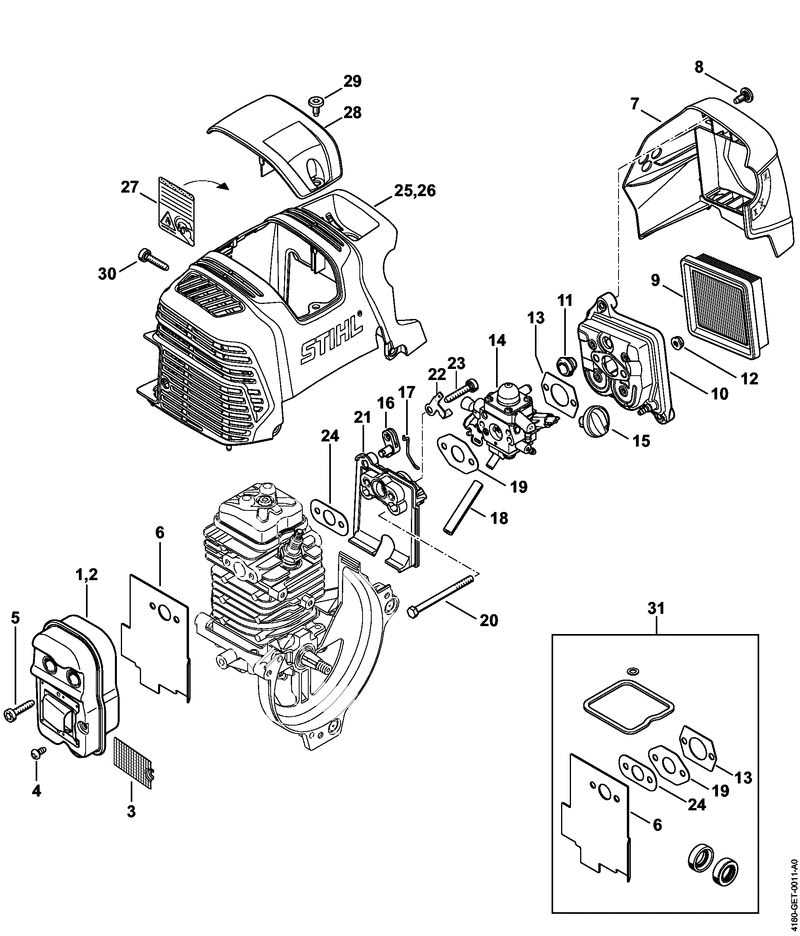

Efficiently identifying the right parts is one of the most important steps in ensuring optimal performance. A visual breakdown allows users to quickly locate each component, assess its condition, and replace it if necessary. Whether you are performing routine maintenance or addressing a specific issue, a well-organized guide can make a challenging task much easier.

In this guide, you will find a comprehensive overview of essential components, helping you navigate through the assembly and identify what needs attention. With this knowledge, you can confidently manage repairs or replacements without confusion, ensuring your machinery continues to deliver reliable performance.

Understanding Key Components of Your Equipment

To ensure your outdoor machinery operates at its best, it’s essential to have a solid understanding of the different components that make up the system. These parts work together to provide functionality and durability, so knowing how each piece contributes to the overall performance is vital. Whether for routine maintenance or troubleshooting, a clear grasp of these components helps in identifying issues and making informed decisions during repairs.

Each part plays a specific role, from the engine system to the transmission and control mechanisms. For instance, the power unit drives the operation, while supporting components, such as the ignition system and fuel delivery, ensure smooth functionality. Knowing these relationships helps in pinpointing potential issues and allows for quicker and more accurate fixes.

By familiarizing yourself with the main elements, you can more easily maintain your equipment, replace worn parts, and keep everything in good working order. Understanding how the pieces fit together also helps in preventing damage caused by improper use or neglect, ultimately prolonging the lifespan of your machinery.

Key Components for Equipment Maintenance

Regular upkeep of outdoor machinery requires attention to several crucial components that keep the system running efficiently. By understanding which elements need frequent checks and maintenance, you can avoid unexpected breakdowns and ensure your equipment continues to function at its best. Some components, such as the fuel system and drive assembly, play a vital role in the overall operation and should be monitored regularly.

Fuel and Ignition Systems

The fuel system is fundamental to the operation of any engine-driven equipment. Regular inspection of the fuel lines, filter, and carburetor helps prevent clogging and ensures a smooth power supply. Additionally, the ignition system, including the spark plug and wiring, needs to be checked periodically to guarantee reliable starts and optimal engine performance. A malfunction in these areas can result in poor functionality and even cause the machine to stop working entirely.

Drive Mechanism and Moving Parts

The drive system is another critical part that requires regular maintenance. This includes checking the gearbox, clutch, and other moving components for wear and tear. Lubrication is key to preventing friction and ensuring smooth operation. Over time, these parts can accumulate dirt and debris, which can cause them to become less efficient or even seize up if not cleaned and serviced properly. Proper care of these components extends the life of your equipment and helps maintain consistent performance.

How to Use the Equipment Breakdown for Repairs

A detailed visual representation of your machine’s components can be an invaluable tool when performing repairs or maintenance. It provides a clear map of each element, making it easier to identify what needs attention. By using such a guide, you can ensure you’re focusing on the correct parts and make the right decisions during the repair process. Knowing how to navigate this visual resource enhances your ability to efficiently fix issues without unnecessary trial and error.

Identifying Key Components

The first step in using the breakdown is learning how to identify each component within the system. These guides typically label every piece, allowing you to pinpoint exactly where an issue lies. Once you understand the layout, you can focus on specific areas that may need attention, such as the power unit, control mechanisms, or fuel system. This approach minimizes confusion and saves time when troubleshooting problems.

Following the Sequence for Assembly and Disassembly

Another key advantage of using a visual guide is its ability to show you the correct sequence for assembly and disassembly. Understanding the order in which components are connected or removed is crucial for preventing damage and ensuring the machine operates as intended. Following the diagram step-by-step can prevent unnecessary complications, especially when reassembling or replacing parts.