When working with outdoor maintenance tools, having a clear understanding of the individual components is essential for proper operation and upkeep. Familiarizing yourself with the various sections of the machinery can help ensure longevity and peak performance. Knowledge of these elements aids in effective troubleshooting and repairs, minimizing downtime during tasks.

One of the key elements of maintaining any outdoor device lies in recognizing the functions of its internal components. Whether you’re replacing a worn-out section or performing regular upkeep, knowing the specific role of each part is crucial. Proper handling and care can significantly extend the device’s life and enhance its efficiency during use.

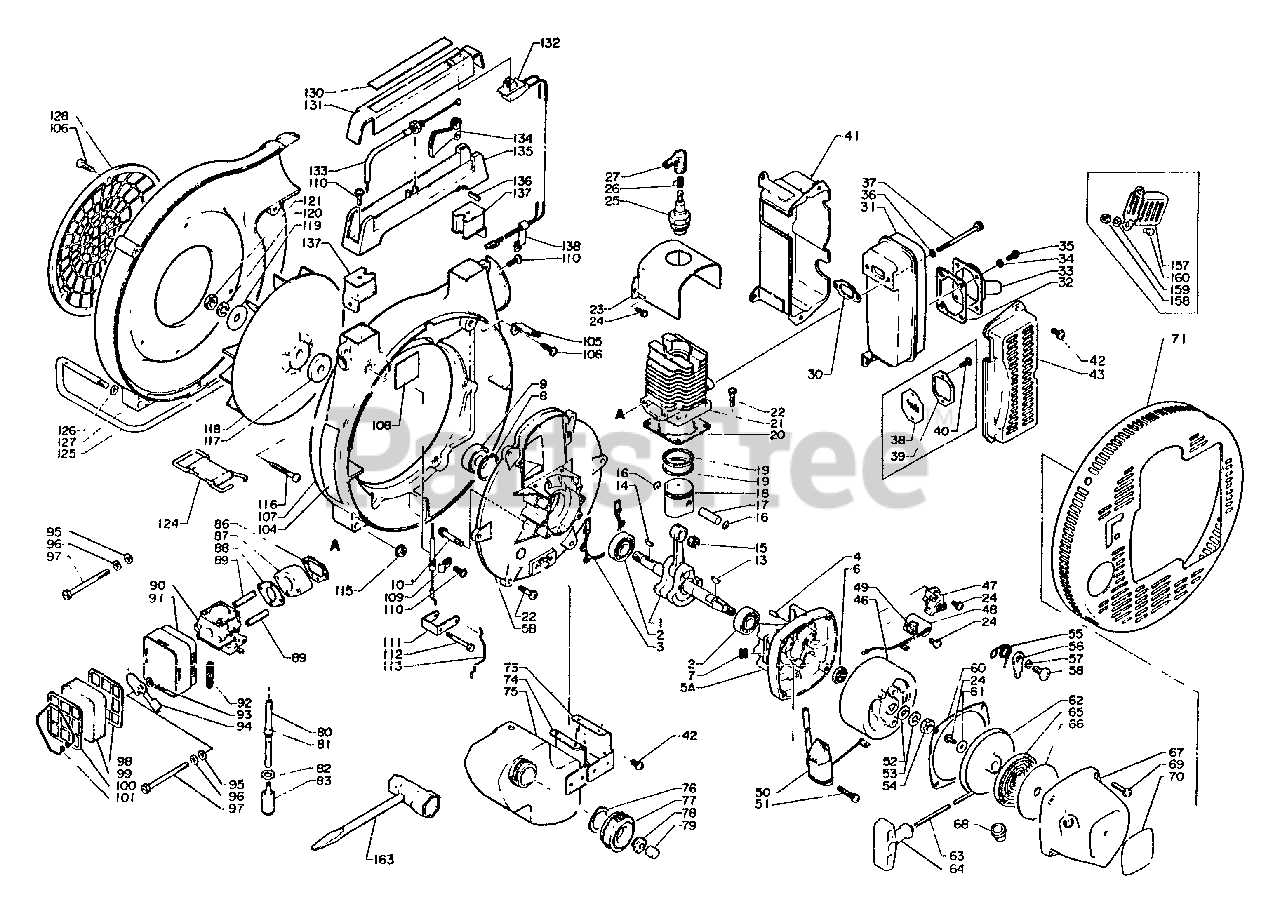

For those involved in maintenance, understanding how each section interacts with the others is invaluable. By referring to detailed breakdowns and guides, users can confidently perform necessary repairs without professional assistance, saving both time and money in the long run.

Understanding Outdoor Equipment Components

Every machine used for outdoor maintenance is made up of various interconnected elements, each serving a specific function. Gaining a deep understanding of these components can help in both the operation and upkeep of the tool. Recognizing the role of each part ensures smooth performance and assists in identifying issues quickly.

Critical Elements of the Machinery

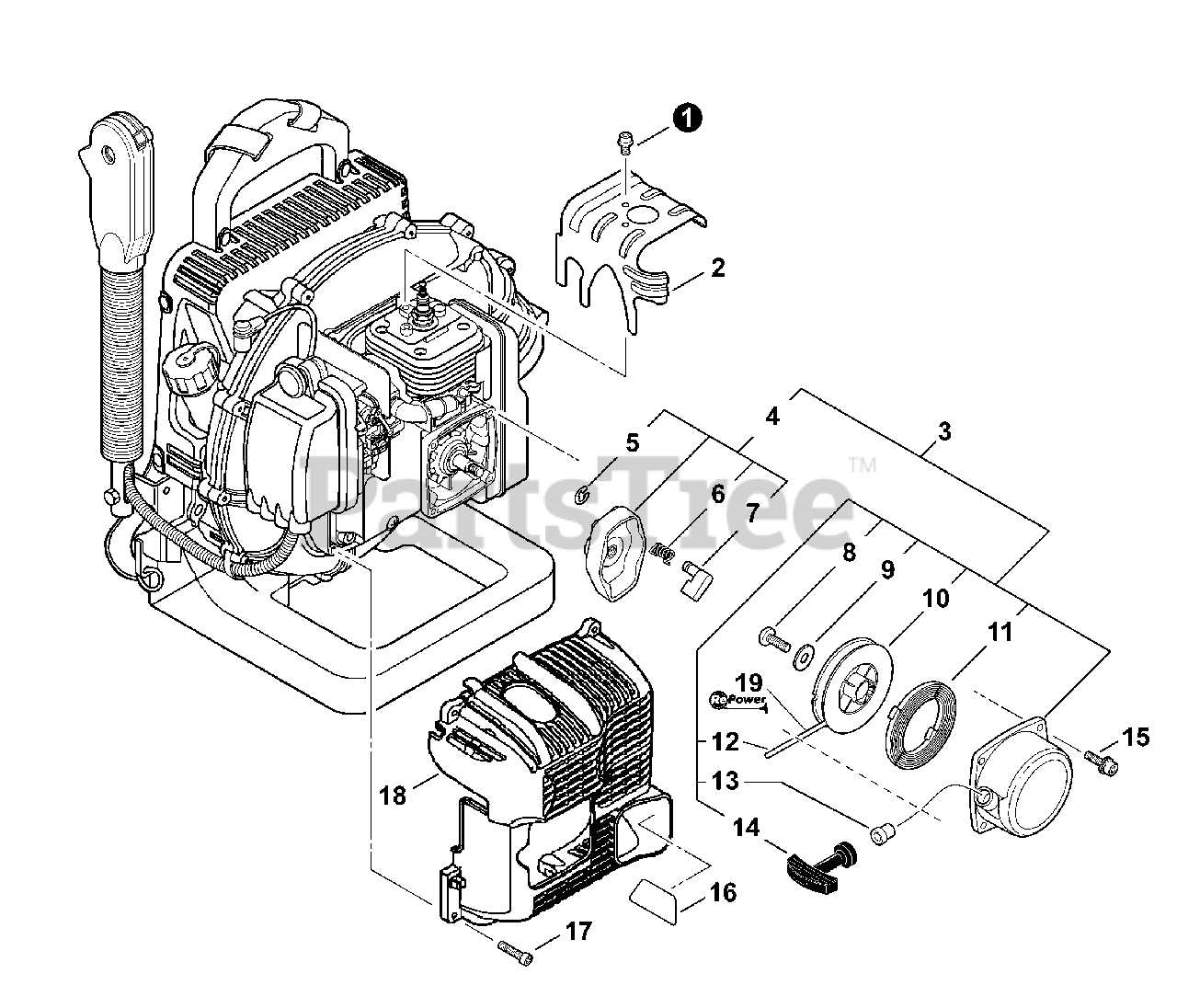

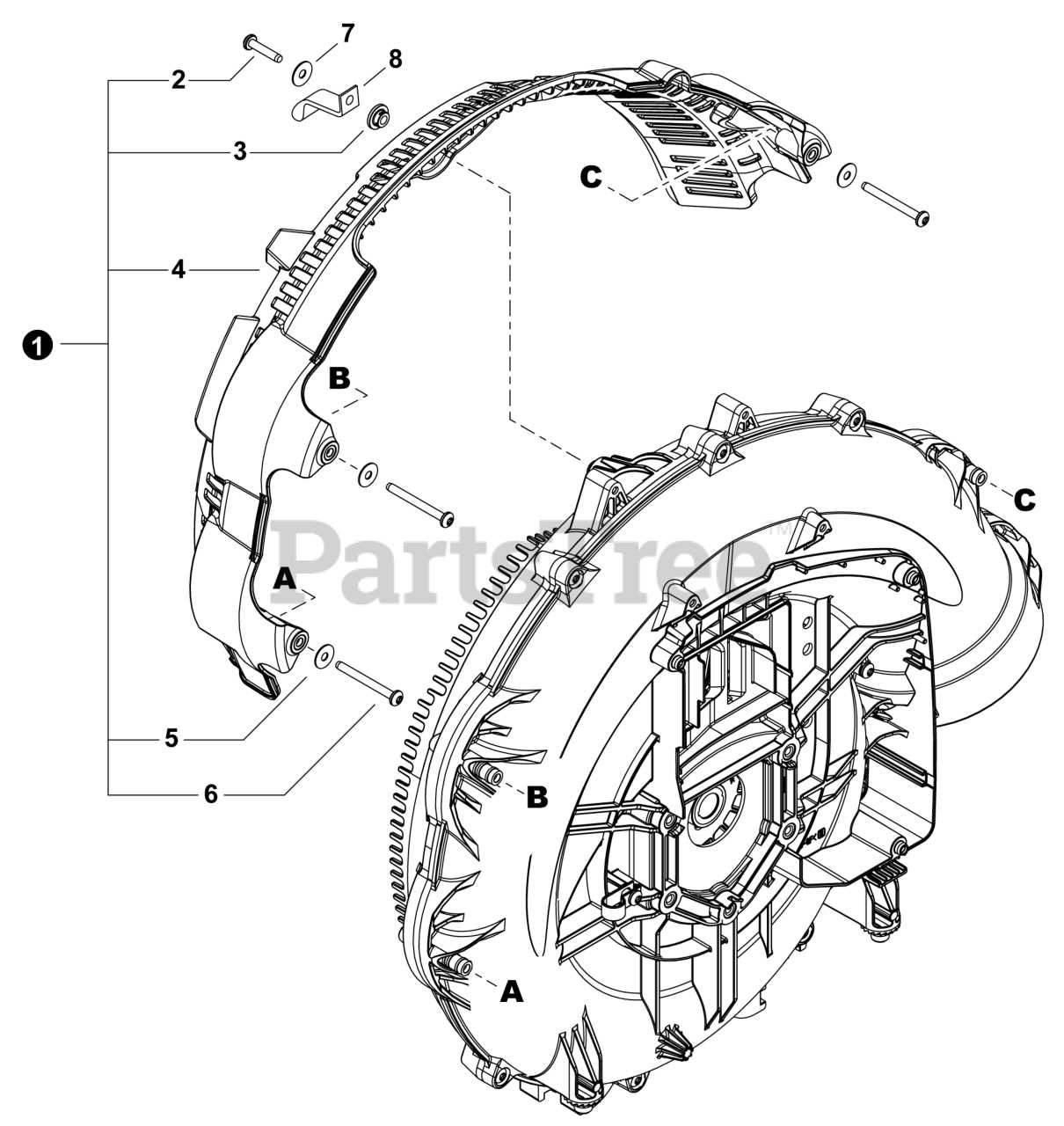

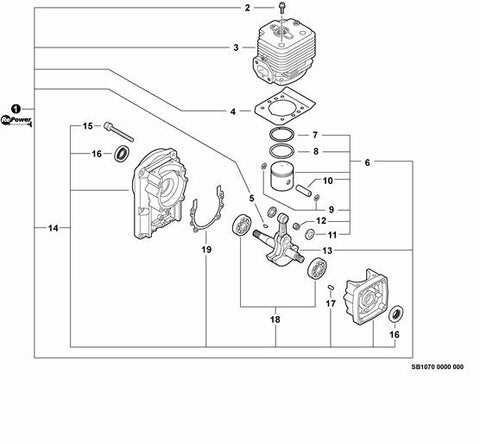

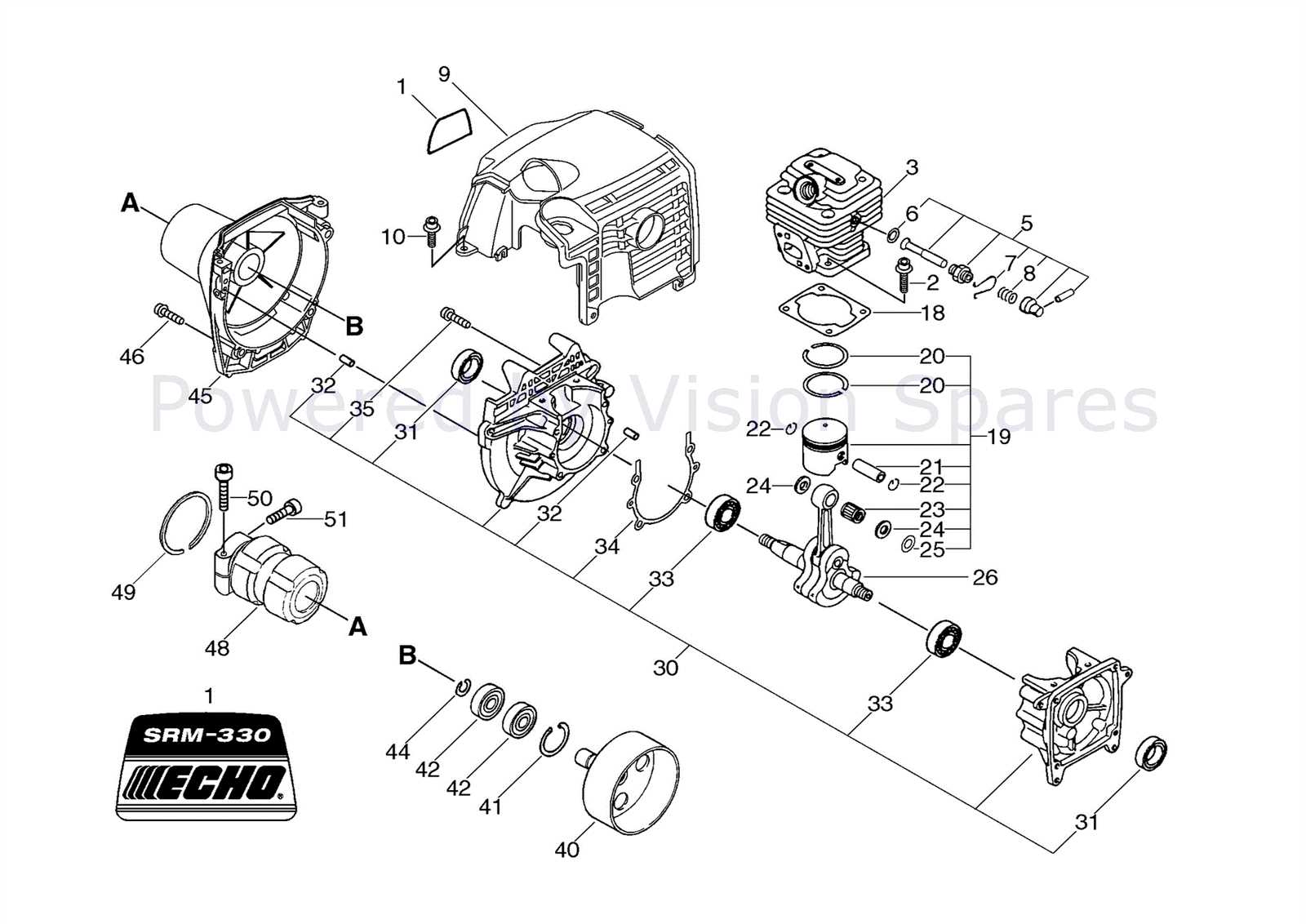

One of the core components of outdoor maintenance tools is the engine. This element powers the machine and is essential for any task. Alongside the engine, other components such as the intake system, exhaust, and power transmission elements play vital roles in the functionality of the equipment.

Maintaining and Troubleshooting the Equipment

Proper maintenance involves regularly inspecting the moving parts, ensuring that everything is securely in place and functioning as intended. Understanding how each part interacts with the others allows users to identify potential issues before they escalate, enabling proactive repairs and reducing the need for costly professional services.

Identifying Key Parts in Outdoor Equipment

Understanding the essential components of any outdoor maintenance tool is critical for effective use and troubleshooting. These devices rely on a combination of key sections that work together to perform the desired tasks efficiently. By recognizing the function of each element, users can ensure smooth operation and address issues promptly.

One of the main components is the engine, which provides the necessary power for the device. The intake and exhaust systems, which control airflow, also play an essential role in maintaining performance. Additionally, the power transfer system, including belts and gears, ensures that the force generated by the engine reaches the working parts to carry out tasks effectively.

Another crucial section is the control system, which allows the user to manage settings and adjust performance levels. Recognizing these components and understanding their functions enables more efficient maintenance, as well as the ability to troubleshoot and replace malfunctioning parts when necessary.

How to Maintain Outdoor Equipment Components

Regular maintenance is key to prolonging the life of any outdoor tool and ensuring its optimal performance. By paying attention to the individual elements and their conditions, users can prevent unnecessary breakdowns and ensure the equipment functions smoothly for a long time. Proper care reduces the risk of major issues and keeps the device running efficiently.

Regular Inspections and Cleaning

One of the most important steps in maintenance is performing routine inspections of the device. Check for wear and tear, especially on moving parts such as the motor and transmission system. Regularly cleaning the components from dirt, debris, and buildup is also crucial. Ensure that air filters and vents are free from obstructions to allow proper airflow, which is vital for the system’s efficiency.

Lubrication and Replacement

Lubricating the moving parts ensures smooth operation and reduces friction that can lead to damage. Pay close attention to components like gears, shafts, and bearings. If any part shows signs of excessive wear or damage, replace it promptly to avoid further complications. Regularly replacing consumables such as spark plugs and fuel filters will also maintain the overall performance of the equipment.