Maintaining a high-performance tool requires knowing its inner workings. Whether you’re an experienced user or a beginner, understanding how each part contributes to overall operation is essential. Having a clear view of the mechanical elements makes troubleshooting, repairs, and replacements much easier. Knowing what each component does allows you to keep the tool in excellent working condition and prevent costly repairs.

In this guide, we will break down the key components of your tool, providing a comprehensive overview to help you identify each piece. This knowledge ensures you can perform necessary maintenance and spot any issues before they affect the functionality. With a solid grasp of the system, you will be equipped to make informed decisions about repairs and upgrades.

Understanding Essential Tool Components

Each piece of equipment is made up of various elements that work together to ensure smooth and efficient operation. Familiarity with the key components is crucial for proper care and maintenance. Understanding how each component interacts will help users troubleshoot issues and extend the lifespan of their tool.

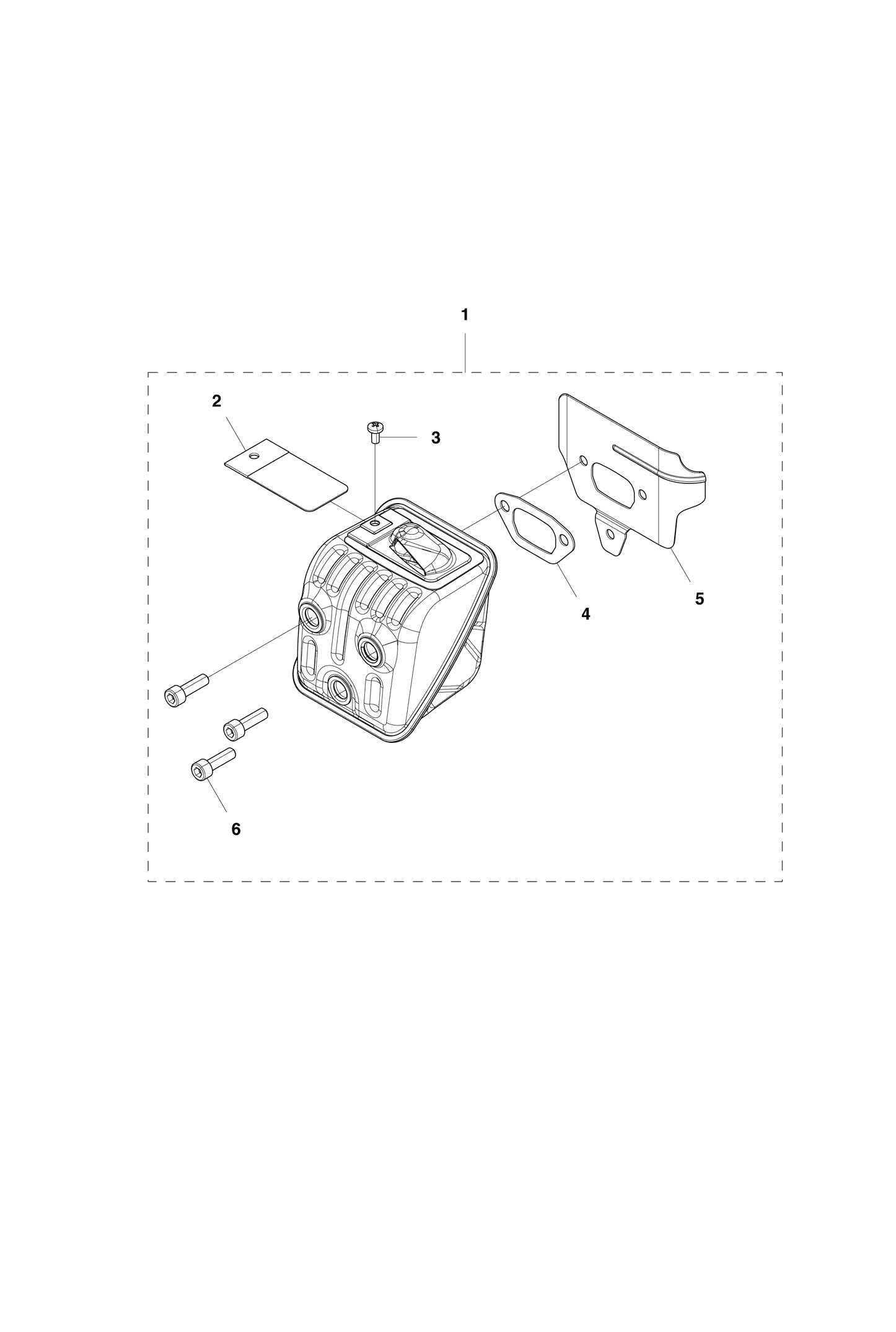

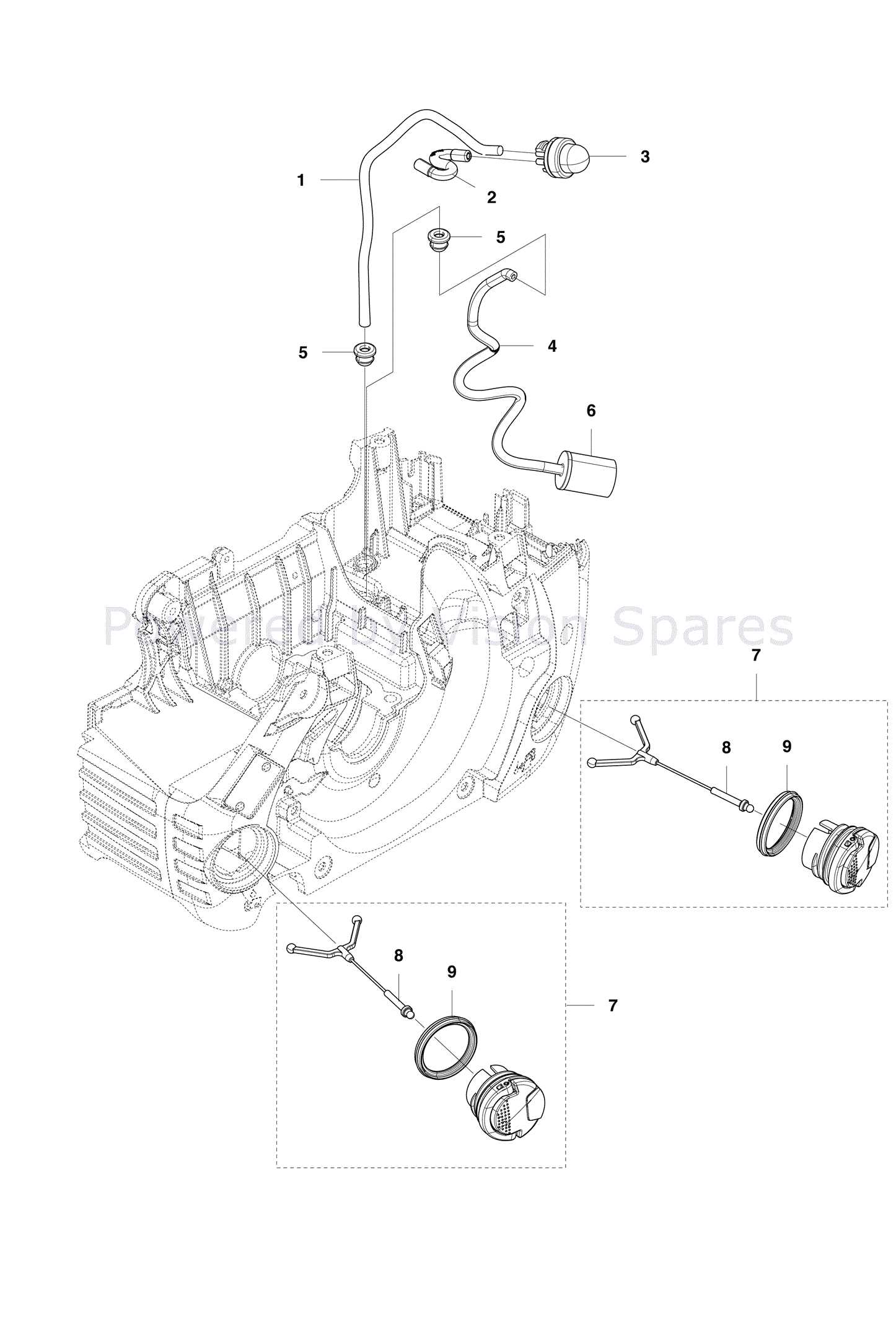

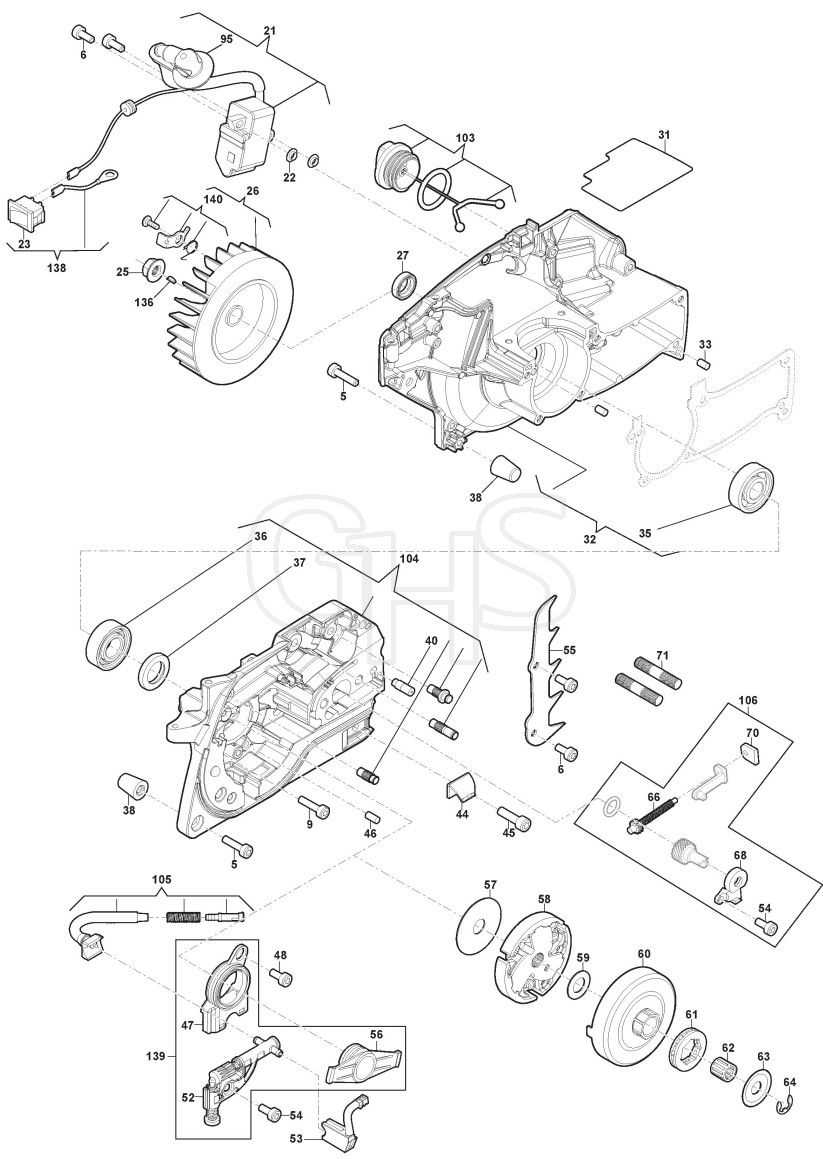

Among the critical elements are the engine system, guide mechanisms, and safety features. These systems are interconnected, and any malfunction in one can affect the overall performance. For instance, the motor drives the cutting mechanism, while other elements, such as the lubrication system, keep it running smoothly and prevent wear.

Recognizing common issues and knowing how to address them is equally important. For example, if a certain component becomes damaged, it is essential to know which other parts might be affected. This awareness can save time and money by avoiding unnecessary repairs or replacements.

How to Identify Tool Components

Properly identifying the individual components of your equipment is key to effective maintenance and repair. By learning the function of each part, you will be able to recognize when something isn’t working as it should. This knowledge also helps when ordering replacements or performing troubleshooting tasks. Knowing each element by sight and function ensures that you address the right issues quickly and efficiently.

Recognizing the Main Elements

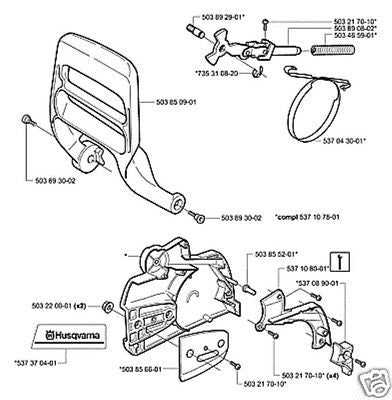

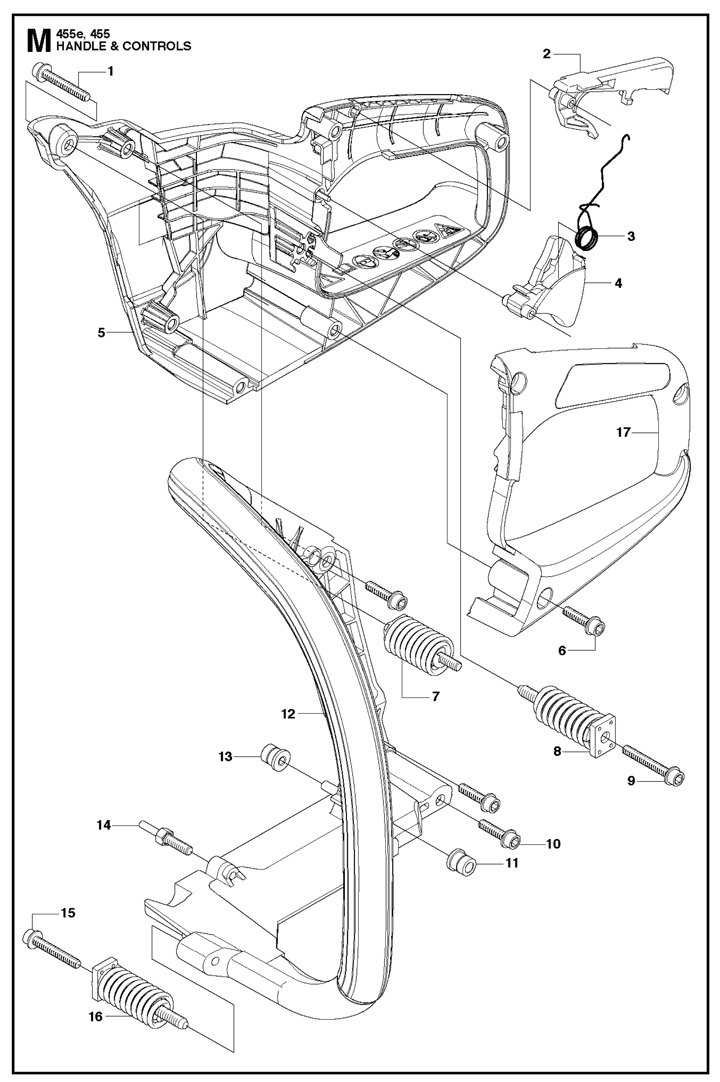

The most important elements to identify include the engine, the drive system, and the safety features. The engine is responsible for powering the mechanism, while the drive system transmits energy to the cutting components. Safety features, such as the brake system, ensure protection during use. These key components are essential for understanding how the entire system works and interacting with it appropriately.

Common Indicators of Wear or Damage

Wear and tear are common in most tools, and knowing how to identify these signs early can save time and money. Look for signs of friction, cracks, or unusual wear on key components like the motor or drive belt. Sometimes, a visual inspection will be enough, but in more complex cases, using a manual or referencing a schematic can help confirm which part needs attention.

Common Issues with Tool Components

Even the most reliable equipment can experience issues over time, especially with regular use. Recognizing these problems early can help avoid costly repairs and ensure continued smooth operation. Some common challenges with essential components can be fixed with basic maintenance, while others might require part replacements or more detailed repairs.

A frequent issue is related to the power system. Over time, the motor or the fuel system may wear out, leading to a drop in performance. Another common problem is damage to the cutting mechanism, which may be caused by regular wear, improper use, or external factors like debris. Additionally, the lubrication system can develop issues, leading to friction and overheating if not maintained properly.

Another important area to check regularly is the safety mechanisms. These features are critical for user protection, and if malfunctioning, they could lead to dangerous situations. A failure in the brake system or safety switch is not uncommon, and addressing these promptly can avoid more serious issues down the line.