Maintaining your garden tools is essential for their longevity and optimal performance. Knowing the different components of your equipment helps in diagnosing issues, performing repairs, and ensuring smooth operation. Proper understanding of the individual elements can make troubleshooting much easier, saving both time and money on repairs.

In this guide, we will explore how to identify the various sections of a lawn tool, how to interpret its mechanical diagram, and which components are most commonly replaced. Gaining insight into these areas will empower you to keep your tools functioning efficiently and extend their useful life.

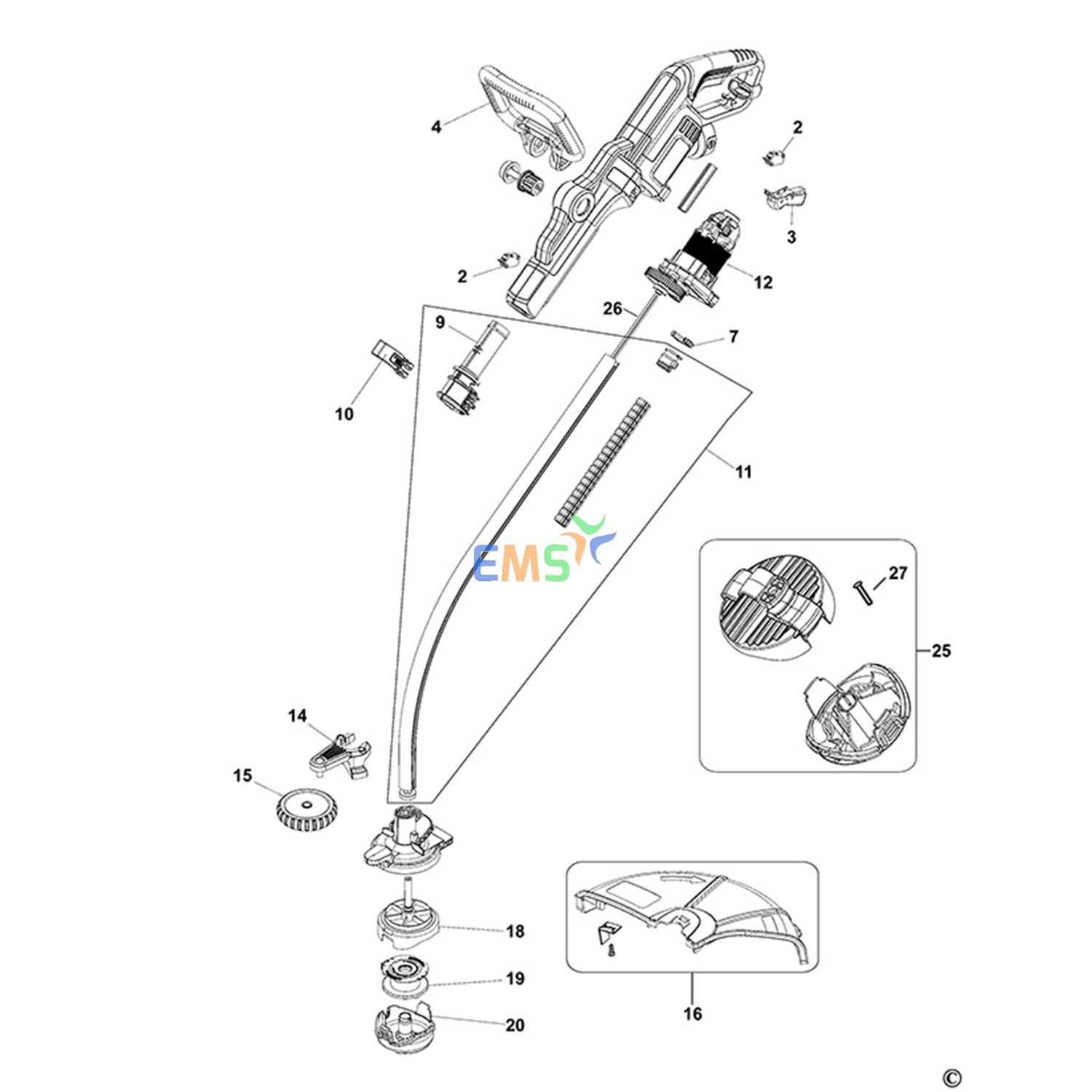

Understanding Lawn Tool Components

Every outdoor device used for trimming or cutting grass consists of several crucial elements that work together to achieve desired results. Identifying these individual sections is key to ensuring proper maintenance and repairs. Familiarity with the tool’s construction will help you troubleshoot any issues and replace malfunctioning pieces with ease.

Below are some of the core components you will find in a typical gardening machine:

- Motor – The heart of the device, responsible for providing the necessary power to operate the cutting mechanism.

- Spool – A vital component that houses the line, which is spun rapidly to trim the grass or other vegetation.

- Handle – Provides the user with control and maneuverability while operating the equipment.

- Trigger – The mechanism that activates the motor and adjusts its speed according to the user’s needs.

- Guard – A protective cover that shields the user from debris and flying particles during operation.

Understanding each of these components allows for better maintenance decisions and an informed approach when troubleshooting. Whether replacing damaged elements or performing routine checks, knowing their roles is crucial for preserving the efficiency and longevity of your tool.

How to Read Lawn Tool Component Schematics

Interpreting the visual representation of your equipment’s components is essential for efficient maintenance. These schematics provide a clear, detailed overview of each part and how they fit together. Understanding the layout and symbols used in these illustrations will help you quickly identify the parts that need attention or replacement.

Here’s how to approach reading these schematics:

- Study the Labels – Each part is typically labeled with a reference number or letter, which corresponds to its description in the manual or parts list.

- Understand the Connections – Look at how the different components connect with each other. This helps in recognizing which parts must be removed or replaced in sequence.

- Check the Legend – Most diagrams include a legend or key to clarify the symbols used for each part, such as arrows for movement or circles for attachment points.

- Follow the Flow – Many schematics are designed to show how power flows through the system, making it easier to troubleshoot electrical or mechanical issues.

By carefully following these steps, you will gain the confidence to navigate the diagram and make the right decisions for repairs or replacements, ensuring your tool continues to function at its best.

Common Replacement Components for Lawn Tool Models

Over time, some components of your outdoor equipment will wear out and require replacement. Regularly checking for wear and tear is essential for maintaining peak performance. Knowing which parts are most commonly replaced can help you prepare for maintenance and avoid unnecessary downtime.

Frequently Replaced Items

Here are some components that often need to be replaced in lawn trimming tools:

- Spool Assembly – As the line gets worn or tangled, replacing the spool ensures the tool continues to trim effectively.

- Trimmer Line – The line is subject to wear from contact with grass, dirt, and other debris, making it one of the most frequently replaced items.

- Motor Brushes – These parts wear down with time and need to be replaced to maintain the tool’s motor performance.

- Battery – For cordless models, the battery will eventually lose its capacity and must be replaced to ensure reliable use.

- Safety Guard – A damaged or worn guard can compromise safety, making it important to replace it when necessary.

How to Determine When to Replace

To identify when a replacement is needed, inspect each part for visible signs of damage or degradation. If the tool’s performance diminishes, such as longer operation times or inefficient cutting, it’s likely time to replace one of these components. Regular maintenance checks can help you avoid unexpected failures.