Every transportation vehicle used in the shipping industry is built with specific elements that ensure it operates smoothly. These components play a crucial role in maintaining the efficiency and safety of cargo transport. Understanding the layout and function of each part helps operators and maintenance teams identify issues early and perform repairs accurately.

In this section, we explore the vital structure of these transportation units. Through detailed representations, we break down the functionality of each component, offering insights into their maintenance needs. With the right knowledge, professionals can ensure that every part is working properly, prolonging the lifespan of the vehicle and reducing downtime.

Understanding the Components of Freight Cars

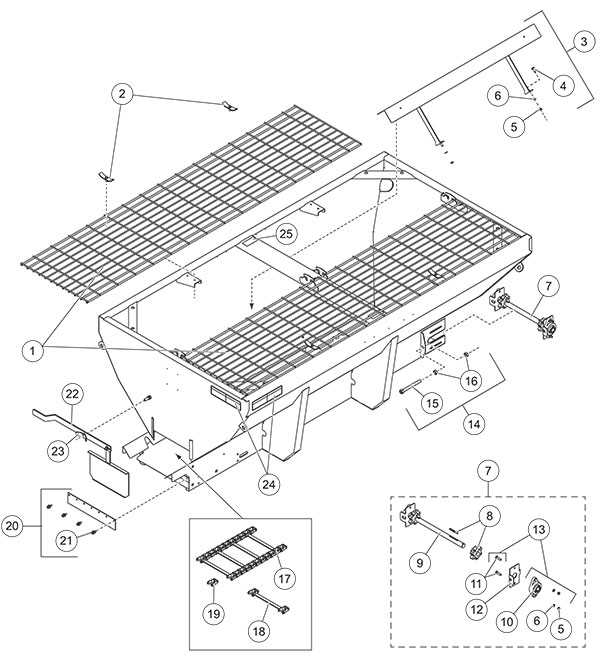

Each vehicle designed for bulk cargo transport is made up of several key elements that contribute to its overall function. These components work together to ensure the smooth loading, unloading, and safe transport of materials. By examining these essential features, it becomes clear how their precise design and interaction are vital to the vehicle’s performance.

The structure includes critical elements that allow for proper weight distribution, secure cargo placement, and easy access for maintenance. For instance, the lower part of the vehicle often includes mechanisms for unloading goods, while the upper portion is built for durability and stability during transportation. Understanding the role of these features can prevent costly repairs and improve operational efficiency.

Furthermore, having a clear understanding of the individual elements that make up the vehicle allows for effective troubleshooting. Proper knowledge of their design helps maintenance teams detect wear and tear, ensuring timely interventions and enhancing the safety of the entire operation.

Key Parts of Freight Vehicles for Repairs

Every transportation vehicle used for bulk cargo is composed of several essential components that require regular inspection and maintenance. These elements ensure the vehicle functions efficiently and safely throughout its service life. Identifying and addressing issues in these critical areas is key to reducing downtime and repair costs.

Some of the most crucial components include the unloading mechanisms, structural beams, and wheel assemblies. Each of these plays a specific role in the vehicle’s operation, from supporting the weight of the cargo to ensuring a smooth transition during unloading. Regular maintenance of these areas is essential to prevent wear and improve overall performance.

In addition, attention should be paid to the locking systems, brake components, and safety features, as these directly impact the vehicle’s ability to operate safely and efficiently. Ensuring these elements are in top condition helps prevent accidents and ensures a longer operational lifespan for the vehicle.

How Freight Vehicle Diagrams Aid Maintenance

Clear and detailed representations of transportation vehicles are invaluable tools for maintenance teams. These visual guides provide a comprehensive overview of the vehicle’s structure and individual components, making it easier to locate and address potential issues. By using these resources, technicians can perform more accurate and efficient repairs.

With a well-detailed visual guide, maintenance professionals can:

- Quickly identify the exact location of any malfunctioning components

- Understand the relationship between different parts and how they interact

- Follow step-by-step instructions for disassembly and reassembly

- Ensure all safety protocols are met during repairs

In addition, such diagrams help streamline communication between maintenance teams. When a problem arises, referencing a diagram allows for clear and effective discussions, reducing the time spent diagnosing the issue and minimizing the risk of errors during repairs. Overall, these visual aids contribute to smoother operations and a higher level of reliability in transportation systems.