Maintaining and repairing your utility vehicle can be a complex task without a clear overview of its internal components. Whether you’re performing routine maintenance or tackling a more extensive repair, having a visual guide can make all the difference. Knowing where each piece fits and how it interacts with others helps to prevent errors and ensures a smoother repair process.

In this guide, we will break down how to efficiently navigate through an essential component map. With a thorough understanding of each segment, you’ll be better equipped to identify faulty parts and find the right replacements. This approach will not only save time but also reduce the chances of costly mistakes.

Familiarizing yourself with the vehicle’s layout is the first step towards becoming more confident in handling repairs. Whether you’re a professional mechanic or a DIY enthusiast, understanding how each component works together is vital for any maintenance task. The more familiar you are with the system, the easier it will be to make informed decisions when servicing your vehicle.

Understanding the Vehicle Components

When it comes to maintaining and repairing your utility vehicle, having a clear understanding of its key elements is essential. Each system, from the engine to the transmission, has specific components that must function together seamlessly. Knowing the layout of these elements will allow you to spot potential issues and address them efficiently, saving time and effort during repairs.

Key Systems and Their Functions

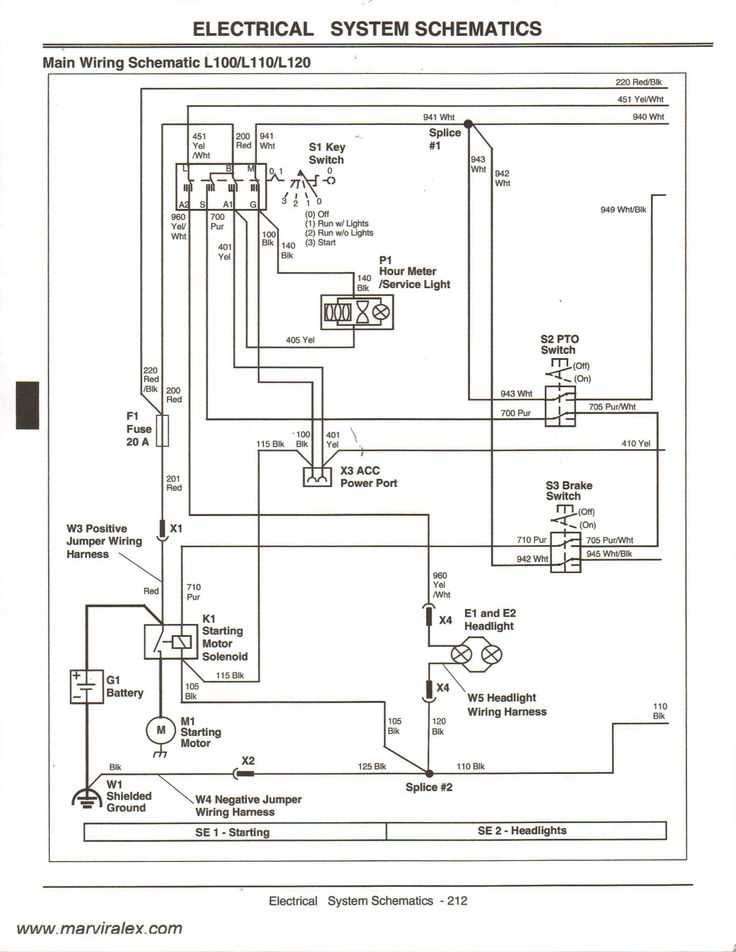

The main systems in any utility vehicle include the drivetrain, electrical system, suspension, and braking mechanism. Each of these systems is composed of multiple interconnected parts that work in unison. The drivetrain, for instance, consists of components that transfer power from the engine to the wheels, while the electrical system powers lights, sensors, and other critical features. Understanding how each system operates individually and in relation to the others can help with troubleshooting and maintenance.

Identifying Components for Quick Repairs

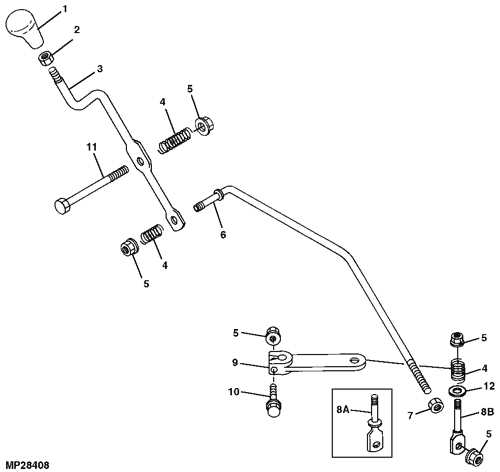

Knowing the precise location and function of each component is crucial when it comes to quick repairs. With a detailed map of the vehicle’s layout, you can easily locate specific parts and replace them without unnecessary delays. A clear overview not only helps with fixing immediate problems but also allows you to plan for preventative maintenance, ensuring that your vehicle remains in top working condition.

How to Read the Component Layout

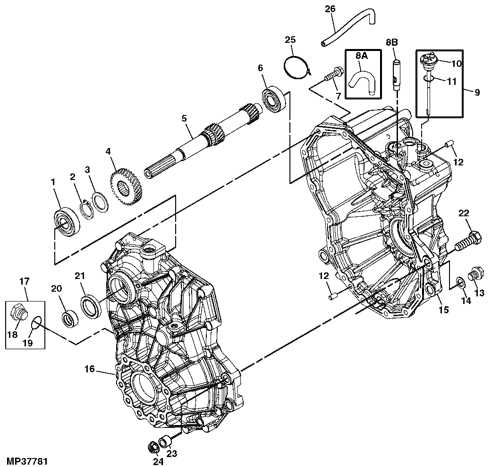

Reading a component map for your utility vehicle may initially seem overwhelming, but once you understand the basics, it becomes a powerful tool for efficient maintenance and repairs. A well-organized layout provides a clear visual representation of how each part fits into the larger system, helping you quickly locate and identify specific elements that may need attention.

The first step in reading such a layout is understanding the different symbols and notations used to represent each part. These may include numbered or lettered tags next to each component, allowing for easy cross-referencing with the parts list. Familiarizing yourself with these identifiers is key to accurately interpreting the map and locating the specific parts in question.

Additionally, pay attention to the relationship between parts. Some components are interdependent, meaning their function is linked to another part of the system. Understanding these connections can help you anticipate potential issues before they arise and ensure that you are replacing the correct elements during repairs.

Common Issues and Replacement Parts

Over time, utility vehicles experience wear and tear that can lead to various mechanical issues. Understanding the most common problems that arise and knowing which components are likely to need replacement will help you maintain your vehicle more effectively. By recognizing these issues early, you can avoid more serious damage and costly repairs.

Frequent Problems in Utility Vehicles

Several common issues often occur due to prolonged use or exposure to harsh conditions. These problems are typically linked to specific systems within the vehicle. The most frequently encountered issues include:

- Engine Malfunctions: Poor performance, unusual noises, or stalling could indicate issues with the engine components.

- Transmission Failures: Difficulty in shifting gears or slippage may suggest a problem with the transmission system.

- Brake Issues: Squeaking, reduced stopping power, or uneven wear on brake pads are signs that brake components need attention.

- Electrical Failures: Malfunctioning lights, gauges, or battery problems often stem from electrical system issues.

Identifying and Replacing Faulty Components

Once the issue is identified, the next step is to locate the specific components that need replacing. Here’s a list of parts that commonly require replacement:

- Fuel filter – a clogged filter can reduce engine performance.

- Brake pads – worn-out pads need to be replaced for proper braking.

- Spark plugs – old or dirty spark plugs can cause misfires or engine hesitation.

- Belt and pulley system – cracked or damaged belts can cause mechanical failure.

- Battery – weak or dead batteries should be replaced to avoid electrical issues.

Regular inspection and replacement of these components will keep your vehicle running smoothly and extend its lifespan.