When it comes to maintaining and repairing outdoor power equipment, understanding its internal structure is crucial. A well-structured breakdown of the machine’s components not only makes the repair process more manageable but also ensures the equipment functions at its best. With proper knowledge, owners can quickly identify issues and take corrective actions.

In this guide, we explore the essential elements of a specific chainsaw model, highlighting its key components. Knowing the role of each part can help troubleshoot common problems and extend the lifespan of the tool. Whether you’re a professional or a hobbyist, having a solid understanding of the machine’s makeup is indispensable.

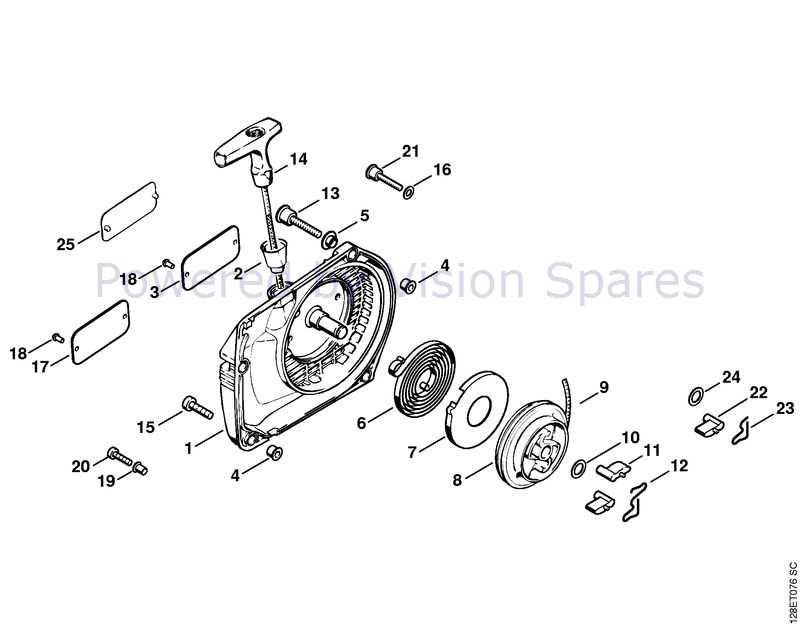

Explore detailed visuals to assist in locating each component and gain insights into their connections. With this knowledge, users can effectively perform maintenance tasks or identify faulty parts that may need replacement. Familiarity with the structure ensures that the tool remains operational for years, delivering optimal performance.

Understanding the Chainsaw Components

To properly maintain any chainsaw, it’s essential to have a clear understanding of its key components and how they work together. Each part of the machine plays a specific role in ensuring smooth operation, and recognizing their function allows for easier troubleshooting and repair. Knowing how the different elements interact can help users diagnose issues more efficiently, leading to quicker fixes and extended tool lifespan.

For example, the engine and its surrounding mechanisms are the driving force of the tool, while the cutting system is responsible for the actual task of felling or trimming. Other critical components, such as the fuel system, ignition, and air filtration, ensure optimal performance and reliability. Familiarity with these elements helps ensure that any repair or replacement is done with precision, minimizing downtime and improving the efficiency of the chainsaw.

Understanding the layout of the machine’s internal structure gives users a better grasp of how to approach repairs. With a detailed knowledge of each section, individuals can confidently identify worn or damaged components and address issues proactively. This insight not only enhances the chainsaw’s functionality but also contributes to safer operation in the long term.

How to Use the Visual Breakdown for Repairs

When repairing any machine, having a clear visual reference of its components can be invaluable. A well-organized schematic allows users to quickly locate and identify each part, simplifying the process of fixing or replacing damaged elements. By following a structured guide, users can avoid unnecessary disassembly and target only the affected sections, saving both time and effort.

Start by identifying the section of the equipment that needs attention. With the reference in hand, locate the corresponding part number or component in the diagram. This ensures that any replacement parts are correctly matched to the machine’s specifications. Once you have the necessary part identified, you can proceed with the repair, whether it’s a simple fix or a more complex replacement.

Using the reference regularly not only improves the accuracy of repairs but also helps familiarize you with the inner workings of the tool. With practice, the breakdown becomes an essential resource, helping you troubleshoot problems more efficiently and enhance your understanding of the machine’s operation.

Common Issues and Solutions for Chainsaw Models

Like any mechanical tool, chainsaws can encounter a range of issues that affect their performance. Understanding the most common problems and their solutions is essential for keeping the equipment running smoothly. Whether it’s difficulty starting, poor cutting performance, or unusual noises, recognizing the symptoms early can save time and reduce repair costs.

One frequent issue is a failure to start, which is often related to problems with the ignition system, fuel supply, or air filter. Ensuring that the spark plug is clean and functional, the fuel is fresh, and the filter is free of debris can often resolve this problem. Another common concern is poor cutting performance, which can be caused by a dull chain or improper tension. Regularly checking the chain sharpness and adjusting its tension can restore the cutting efficiency.

Unusual vibrations or excessive noise may indicate a loose component or a problem with the engine’s internal parts. In these cases, it’s important to inspect the machine for any loose bolts, damaged gaskets, or worn-out bearings. Regular maintenance and prompt attention to these issues can greatly extend the lifespan of the tool and ensure optimal performance over time.