When maintaining or repairing outdoor cleaning equipment, having a clear understanding of its internal structure is essential. The breakdown of various elements allows users to identify where issues may arise and how to approach fixing them. Familiarizing yourself with these essential components ensures smoother operation and prolonged lifespan of your machine.

By examining the layout of key components, users can troubleshoot problems with greater accuracy. Recognizing each part’s function and location simplifies maintenance tasks, whether you’re replacing a faulty piece or conducting routine checks. This knowledge empowers you to handle your equipment more efficiently and confidently.

Proper maintenance not only enhances performance but also minimizes the need for costly repairs. Knowing the right approach to managing your machine can save both time and money in the long run. With the right resources, anyone can improve their ability to care for and repair their equipment independently.

Understanding the Simpson 3200 PSI Components

When operating outdoor cleaning machinery, it’s important to know the different elements that make up the system. These parts work together to ensure the effective functioning of the equipment. Each component has a unique role, and understanding how they interact can help with both routine maintenance and troubleshooting.

At the core of the machine is the engine, which powers the entire system. The pump, driven by the engine, is crucial for generating the force required for the cleaning task. Other essential components, like hoses and nozzles, control the flow and direction of the output, while the frame holds everything in place, ensuring stability during use.

Knowing how these individual parts work together gives users the ability to maintain the system better. For instance, understanding the pump’s operation helps with diagnosing issues like low output or irregular spraying. Proper knowledge of each component’s function also makes it easier to identify what needs attention during routine inspections or when parts show signs of wear.

How to Read the Pressure Washer Diagram

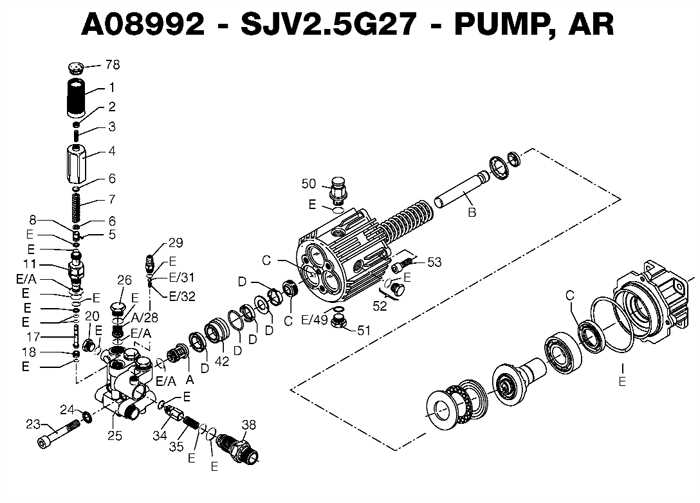

Interpreting the layout of the cleaning machine’s components is essential for effective maintenance and troubleshooting. A well-detailed schematic provides a visual representation of how each element is connected, helping users understand the flow of operation and pinpoint areas for repair or replacement. Understanding how to read this guide can simplify the process of identifying problems and performing necessary fixes.

The first step is to recognize the symbols used to represent various parts. Each component is usually depicted with standardized icons or labels, making it easier to locate specific items. Pay attention to the lines that connect these components, as they represent the paths through which energy or fluid travels, such as fuel or water. This will give you insight into how the system operates as a whole.

Next, focus on identifying the key sections within the layout. Often, the diagram will highlight important components such as the engine, hoses, and connections. Understanding these major areas allows you to follow the diagram effectively and makes it easier to find potential problem spots during inspections or repairs.

Common Issues and Fixes for Parts

As with any mechanical equipment, certain issues tend to arise over time. Recognizing common problems and knowing how to address them can save you time and prevent unnecessary damage. Whether it’s a decrease in performance or an unusual noise, understanding the typical malfunctions of your machine’s components allows you to act quickly and effectively.

Low Output or Loss of Power

One of the most common issues users face is a noticeable decrease in output or power. This can be caused by a variety of factors, including clogged nozzles, a malfunctioning pump, or insufficient fuel. Checking the nozzle for blockages or debris is a good first step, followed by inspecting the pump to ensure it’s working correctly. If the pump is the issue, it may need to be repaired or replaced.

Leaks or Drips from Hoses

Leaks or dripping water from hoses are another frequent problem. This can occur due to worn-out seals or cracks in the hose material. Inspect the hoses for visible signs of wear and replace any damaged sections. Regularly checking the connections and ensuring they are tightly secured can also prevent leaks and help maintain optimal function.