Maintaining machinery requires a clear understanding of its internal structure and components. A well-organized layout of these elements is crucial for effective repairs and regular upkeep. Knowing where each part fits allows for faster troubleshooting and minimizes downtime.

For machine owners and technicians, having access to a comprehensive guide can significantly enhance the efficiency of maintenance tasks. These guides help identify parts, recognize potential issues, and improve the overall understanding of the system. By consulting such a guide, users can ensure optimal performance and longevity of their equipment.

In this section, we will explore how to use visual references to navigate through machine components. Whether performing routine checks or addressing specific concerns, the ability to quickly locate parts will streamline operations and reduce costly delays.

Understanding the Kubota Z411 Parts Layout

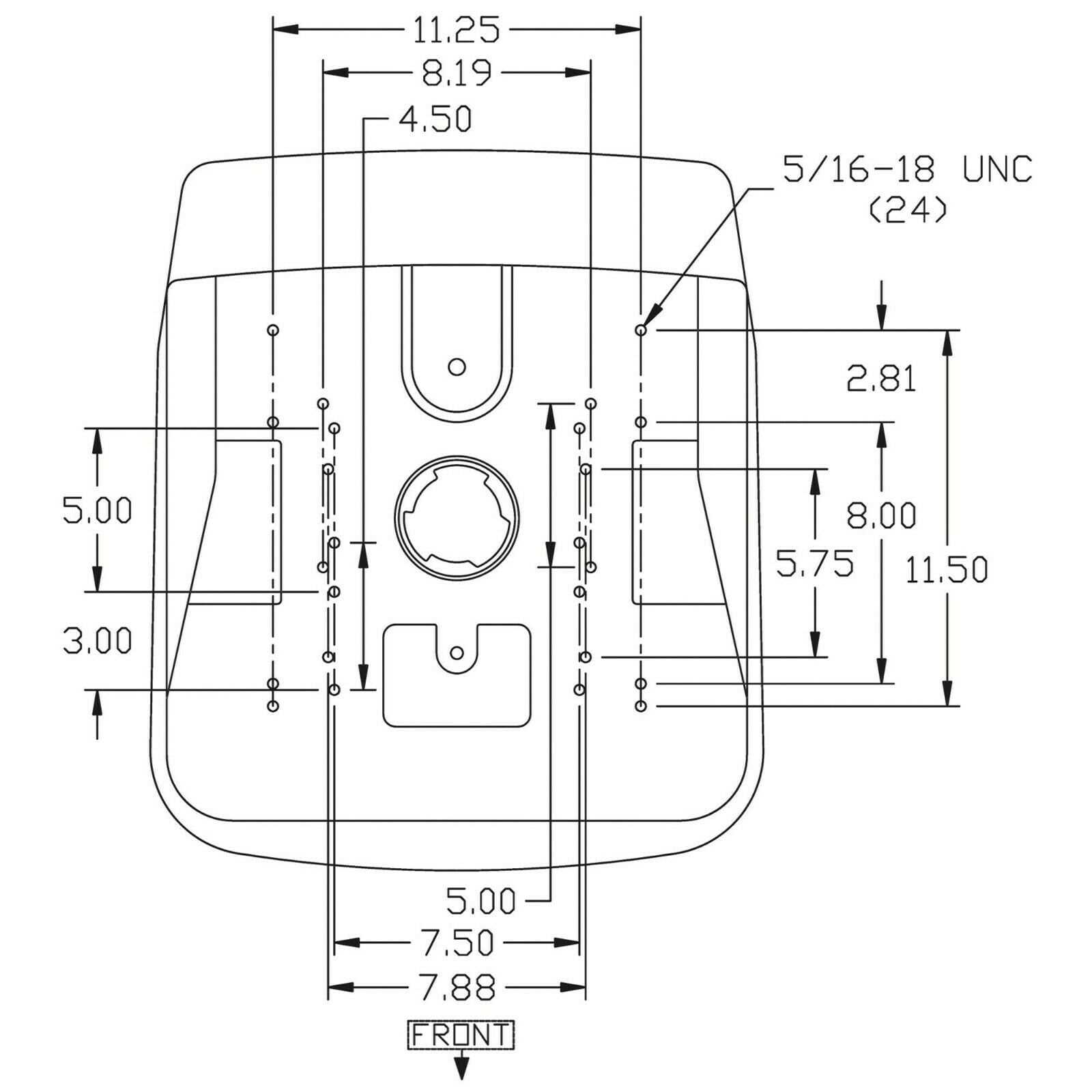

Proper knowledge of how a machine’s internal components are arranged is essential for efficient maintenance and repair. A clear, visual representation of the system allows operators to pinpoint the exact locations of each element, ensuring that tasks can be performed with minimal time and effort.

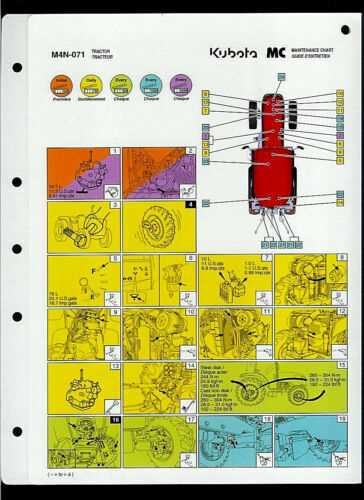

When examining such a layout, it’s important to understand the function of each section within the machinery. Different areas are responsible for specific processes, such as power transmission, cooling, and structural support. This understanding helps to streamline the diagnostic process and ensures that repairs are carried out accurately.

Key Areas to Focus On

Focusing on critical areas, such as the engine compartment and control systems, is vital. These sections house the primary moving parts that ensure the machinery operates smoothly. Familiarity with their placement can assist in preventing major malfunctions and identifying minor issues early on.

Benefits of a Clear Layout

A well-organized layout contributes to efficient troubleshooting, allowing technicians to quickly locate faulty components. It also reduces the likelihood of unnecessary disassembly, which can cause additional wear or misalignment of parts. With this structured approach, operators can maintain a high level of performance and extend the lifespan of the machine.

Key Components of Kubota Z411 Engine

Understanding the crucial elements within an engine is vital for ensuring its smooth operation and longevity. Each component has a specific role, working together to provide power, efficiency, and stability. A clear grasp of these key sections allows for precise maintenance and helps in identifying potential issues before they escalate.

Engine Core and Power Generation

The heart of the machine lies within the engine block, where fuel and air are mixed to generate power. This core assembly includes essential elements such as pistons, crankshafts, and cylinders. These components work in harmony to convert fuel energy into mechanical motion, driving the machine’s operations.

Cooling and Lubrication Systems

Another critical section is the cooling and lubrication systems. The cooling system ensures that the engine doesn’t overheat by circulating coolant through the engine block, while the lubrication system keeps moving parts properly greased to reduce friction and wear. These systems are crucial for maintaining efficient performance and preventing overheating or component damage.

How to Use the Kubota Z411 Parts Diagram

Utilizing a visual guide to locate and identify the components within a machine is essential for efficient troubleshooting and repair. By referencing this tool, technicians can quickly find the exact location of each element, allowing for faster diagnostics and repairs. Understanding how to navigate this visual map is crucial for proper machine upkeep.

Step-by-Step Navigation

Start by familiarizing yourself with the layout. The guide typically organizes components into sections based on their function, such as engine, transmission, and cooling systems. Begin by focusing on the main components that need attention and trace their connections within the layout. This will help you understand the relationships between parts and how they affect the machine’s performance.

Identifying Specific Components

Once you’ve located the relevant section, look for labeled parts that need attention or replacement. Each component should be clearly marked, allowing for quick identification. Pay close attention to reference numbers or codes next to each part, as these can be cross-referenced with a parts catalog to find the exact replacement or maintenance information.