Understanding the various components of your agricultural machinery is crucial for efficient operation and long-lasting performance. Identifying the specific parts, their functions, and how they work together can greatly assist in keeping your equipment in top condition.

By familiarizing yourself with the structure and mechanical layout, you can ensure timely repairs and replacements when necessary. This knowledge also helps in diagnosing problems early and reducing the risk of more extensive damage.

Proper maintenance not only extends the lifespan of the machinery but also enhances its effectiveness in tackling tough tasks. With a detailed understanding of the inner workings, you’ll be better prepared to make informed decisions on part replacements and adjustments.

Through this guide, you’ll gain insights into the critical elements that make up the machinery, along with valuable tips for smooth operation and upkeep.

Understanding Equipment Components

To maintain and operate your agricultural machinery efficiently, it’s essential to have a clear understanding of its core elements. Each component plays a specific role in ensuring smooth functionality, and recognizing their functions can significantly improve maintenance practices. A thorough knowledge of these parts not only helps in troubleshooting but also aids in preventing potential failures that could interrupt operations.

Key Elements of the Mechanism

At the heart of the equipment lies the cutting mechanism, which is designed to handle tough vegetation and ensure a clean, even cut. This system typically includes blades, spindles, and drive shafts, all working in sync to deliver optimal performance. Understanding how these components connect and operate together is crucial for addressing any issues related to the cutting efficiency or damage during use.

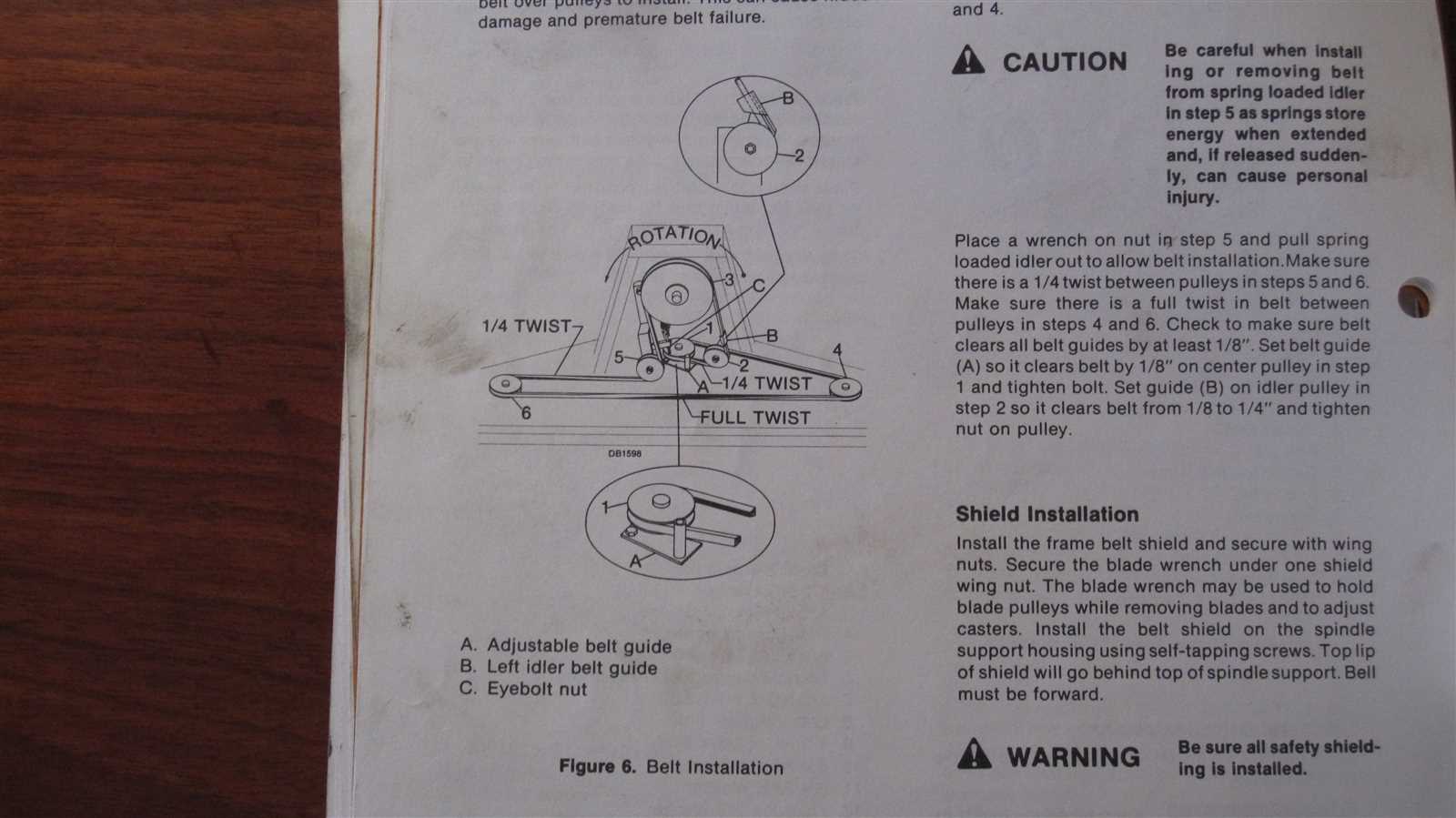

Drive and Power System

The drive system is responsible for powering the machine’s movement and action. It includes the gearbox, pulleys, and belts, all of which transmit energy from the engine to the cutting mechanism. Regular inspection of these components ensures they are functioning smoothly, preventing wear and tear that could lead to mechanical failure. A well-maintained drive system ensures that the equipment performs its intended tasks without unnecessary strain or breakdowns.

How to Identify Essential Equipment Components

Recognizing the individual elements of your machinery is an important step in effective maintenance. By learning to identify each component and its specific function, you can address issues quickly and keep the equipment running at its best. Proper identification ensures you are using the correct tools and replacement parts when necessary, preventing costly repairs.

Identifying the Cutting Mechanism

The cutting system is one of the most vital parts of any agricultural equipment. Key components include the blades, spindles, and the protective shield around the cutting area. These parts are typically made from durable materials, designed to withstand harsh conditions. Familiarizing yourself with these parts helps to recognize wear and tear or any damage that may affect performance. Regular checks for blade alignment and sharpness can prevent uneven cutting or excessive strain on the motor.

Recognizing the Drive Components

The power transmission system transfers energy from the engine to the cutting mechanism. It includes the gearbox, pulleys, and drive belts. These parts are essential for ensuring smooth operation and efficient energy transfer. If the machine begins to lose power or shows signs of slipping, it’s crucial to check these components for signs of wear. Proper identification of these elements is necessary to keep the equipment running smoothly and to replace any worn-out components as needed.

Common Issues and Replacement Tips

Even with regular maintenance, agricultural machinery can experience wear and tear over time. Recognizing common problems and understanding when to replace parts can help prevent further damage and keep the equipment functioning properly. Addressing minor issues promptly can extend the life of the machine and reduce costly repairs in the future.

Worn Blades and Cutting Efficiency

One of the most frequent issues encountered is dull or damaged blades, which can result in poor cutting performance. As the blades wear down, they may not cut as efficiently, leading to uneven or ragged results. If you notice that the machine is struggling to cut through vegetation, it may be time to replace the blades. Ensure you select high-quality replacements that match the specifications of your machine for optimal performance.

Slipping or Broken Drive Belts

The drive system is vital for transferring power to the cutting mechanism. Over time, belts can become loose, cracked, or broken, which can lead to a loss of power or even complete failure. If you hear unusual noises or notice a decrease in efficiency, it could be a sign of a malfunctioning belt. Inspect the drive system regularly, and replace any worn or damaged belts immediately to avoid further complications.