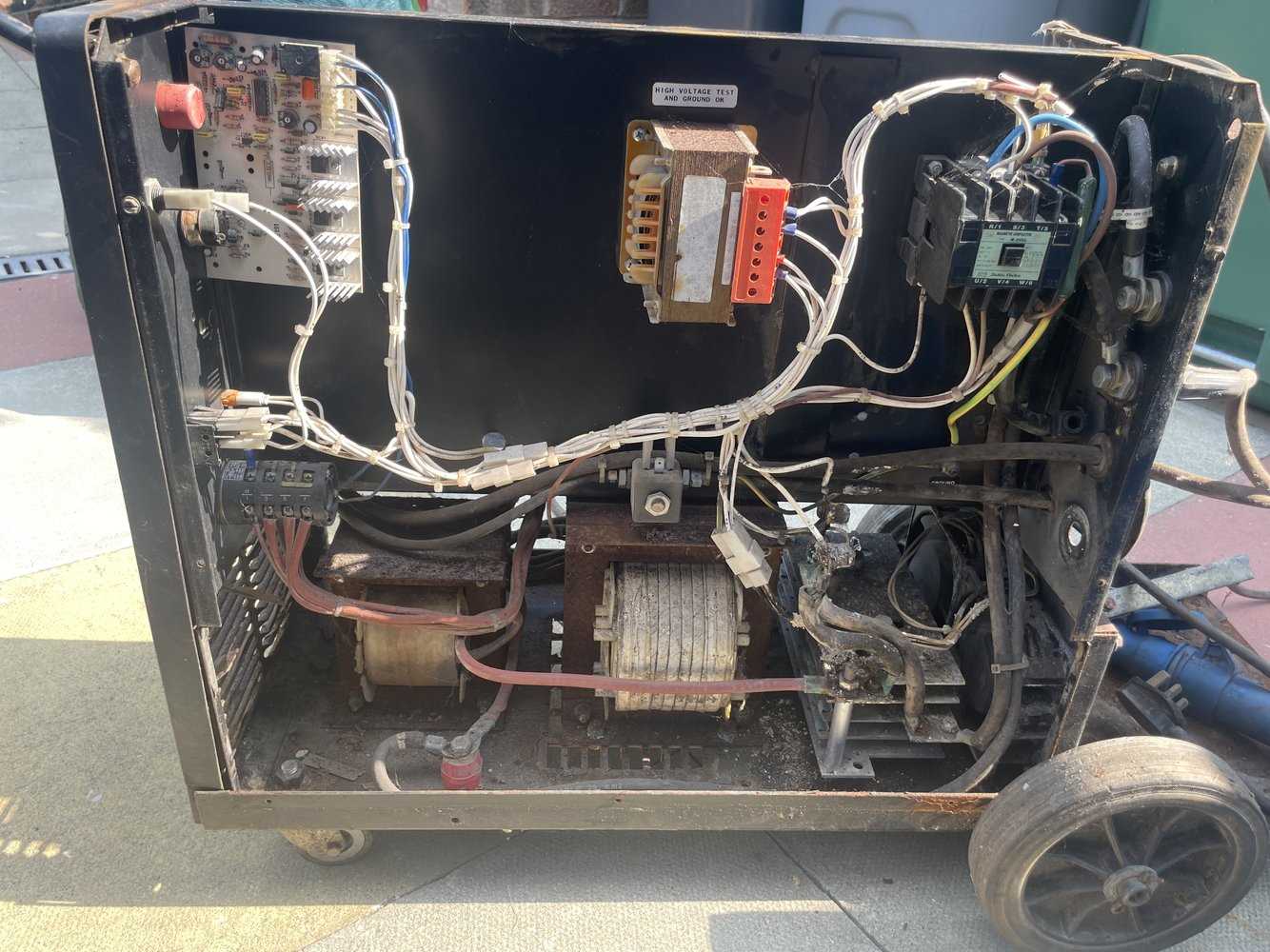

Understanding the intricate details of a welding machine?s structure is crucial for proper maintenance and troubleshooting. This guide delves into the various elements that make up a complex system, offering insights into their roles and how they interact within the entire mechanism.

Accurate identification of each part allows for more efficient repairs and ensures that every component is functioning at its best. Familiarizing yourself with the internal layout can save time and resources, especially when facing specific issues or planning upgrades.

By examining the relationships between each individual piece, users gain a clearer perspective on the machine?s operation and can make more informed decisions regarding repairs or replacements. This overview provides a step-by-step look at how everything fits together, making it easier to navigate the assembly during repairs.

Understanding the Machine Components

When working with a welding unit, it’s essential to have a thorough understanding of the various elements that make up its structure. Each component plays a specific role, contributing to the overall functionality and performance. Recognizing the purpose of these parts allows for more efficient troubleshooting, repair, and maintenance.

Core Components of the System

At the heart of the unit, there are key components responsible for the welding process. These include the power supply, wire feed mechanisms, and control circuits. Each of these plays a crucial part in ensuring that the machine operates smoothly and delivers the desired welding output. Familiarizing yourself with these critical elements is vital for understanding how the system works as a whole.

Supporting Elements and Auxiliary Parts

In addition to the core components, there are various supporting parts that enhance the machine?s overall performance. These can include cooling systems, safety features, and connectors that facilitate smooth operation. While they may not be directly involved in the welding process, they ensure the unit runs efficiently and safely over extended periods. Understanding these auxiliary parts is just as important for maintaining optimal function.

Key Parts in the Machine Assembly

Understanding the essential components of a welding unit is crucial for its operation and maintenance. These key elements interact with each other to ensure efficient performance, with each part serving a unique function. Identifying these components helps in both troubleshooting and optimizing the system’s performance.

Primary Power and Control Systems

The core of the unit includes components responsible for power conversion and control. These systems manage the flow of electricity, adjusting the output to suit different tasks. Understanding these elements is fundamental for any maintenance, as issues in these areas can directly affect the unit’s functionality and safety.

Feeding and Cooling Mechanisms

Feeding mechanisms play a vital role in ensuring the continuous operation of the welding process. They regulate the flow of material, while cooling systems prevent overheating, allowing the unit to work for extended periods. These supporting systems are critical for maintaining the overall health of the machine and prolonging its lifespan.

How to Use the Machine Component Layout

Using a detailed layout of a welding unit?s components can significantly simplify the process of identifying and fixing issues. By referring to this layout, users can quickly locate specific elements, understand their connections, and determine whether they need maintenance or replacement. This visual reference is essential for both beginners and experienced technicians to navigate the system effectively.

Start by familiarizing yourself with the overall structure and the placement of major components. Once you understand the general layout, you can zoom in on individual elements to explore their specific functions and connections. This approach allows for more targeted troubleshooting, helping you identify potential issues without needing to dismantle the entire unit.

Using this tool for reference also makes repairs and upgrades much more efficient. Instead of relying solely on memory or guesswork, the layout ensures you can verify the location and compatibility of parts, allowing for smoother replacements and adjustments. Whether you?re conducting routine maintenance or resolving specific problems, this visual guide is an invaluable asset for maintaining optimal performance.