When it comes to maintaining and repairing small outboard motors, having a clear understanding of the internal components is crucial. Knowing how each part fits together ensures better performance, longevity, and efficiency. Whether you?re a professional mechanic or a boat owner, understanding the layout of the engine can make a significant difference during maintenance or troubleshooting.

Proper identification and knowledge of the motor’s core elements can help streamline repair processes, saving both time and resources. This section provides an overview of essential components and their roles in ensuring optimal function. By familiarizing yourself with how everything connects and operates, you will have a clearer picture of how to address potential issues when they arise.

Mastering these key areas is the first step towards becoming proficient in motor care, allowing you to perform tasks with confidence and accuracy. The next section will guide you through the assembly and identification of crucial parts, empowering you to approach any mechanical challenge with ease.

Understanding the Engine Components

To ensure the smooth operation of an outboard motor, it’s essential to understand the core elements that make up the engine. Each component plays a crucial role in the overall performance and efficiency of the machine. From the ignition system to the fuel delivery components, every part works in harmony to power the vessel reliably and safely.

Some of the key elements include the cylinder head, crankshaft, and carburetor, which are responsible for generating power and managing fuel intake. Additionally, the cooling system, which often includes a water pump, ensures that the engine remains at an optimal temperature during operation. Understanding how these components interact can help diagnose issues, perform repairs, and even improve the overall performance of the motor.

Whether you are maintaining the engine yourself or seeking professional help, a comprehensive understanding of these fundamental components will guide you in making informed decisions. Recognizing the function of each part allows you to approach maintenance tasks with confidence, ensuring the longevity and reliability of your motor for years to come.

Key Components of the 4 Stroke Model

Understanding the critical elements of a four-cycle engine helps ensure proper function and efficient operation. Each component has a unique role in generating power, managing fuel, and maintaining engine health. From the intake valve to the exhaust system, the interaction between these parts is essential for optimal performance.

Key components include the piston, which moves within the cylinder to compress the fuel mixture, and the camshaft, which controls the timing of the intake and exhaust valves. The crankshaft, responsible for converting the linear motion of the piston into rotational energy, plays a vital role in the power generation process. Additionally, the fuel delivery system ensures the correct amount of fuel reaches the engine, while the lubrication system keeps all moving parts functioning smoothly and prevents overheating.

Each of these elements must function in unison to achieve maximum efficiency. Regular maintenance and an understanding of how these components work together can help you identify issues early, ensuring the engine continues to operate at peak performance for years to come.

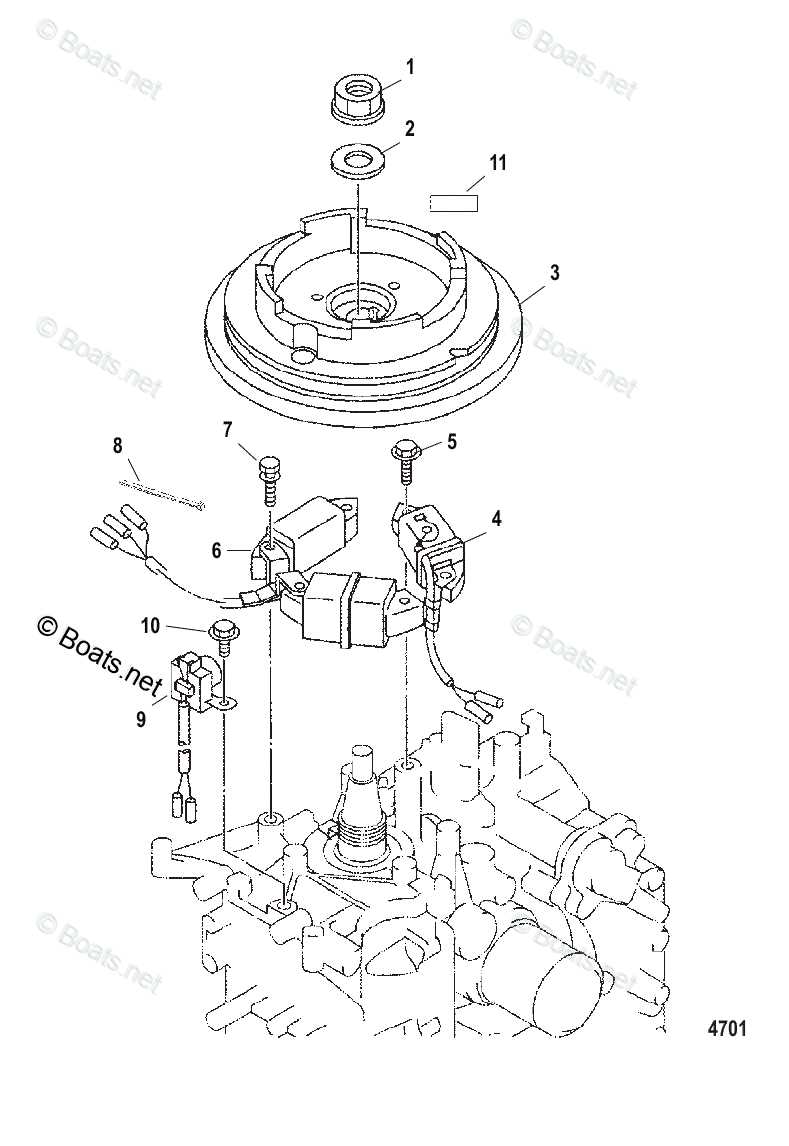

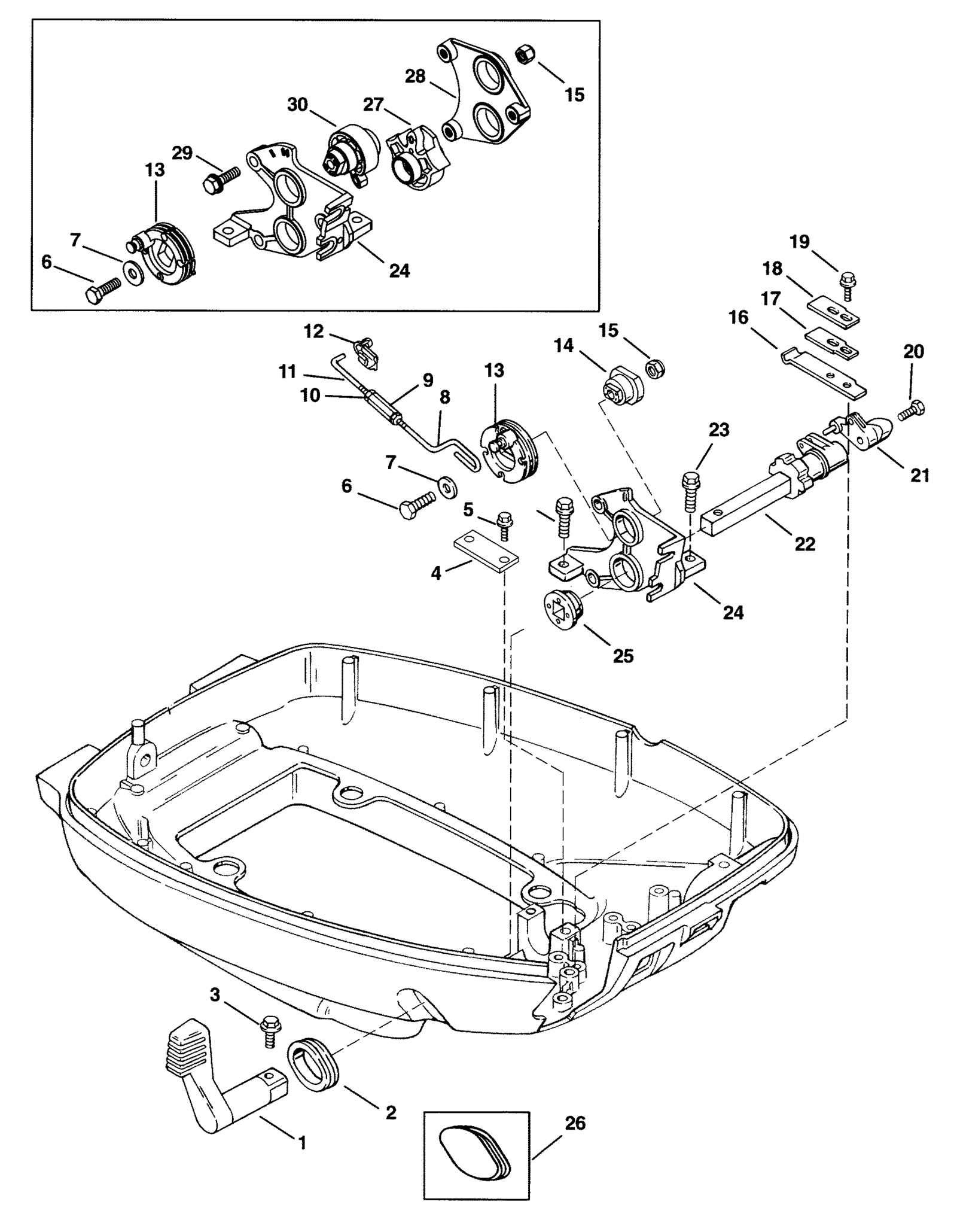

How to Read the Engine Component Layout

Understanding how to interpret a motor’s component layout is essential for effective maintenance and repairs. A clear schematic provides a visual guide to each part and its relationship to other elements, helping you identify their function and positioning. This knowledge is crucial for anyone looking to troubleshoot issues or assemble and disassemble the engine efficiently.

First, familiarize yourself with the overall structure of the engine. Most diagrams are divided into sections, each focusing on different aspects of the motor, such as the ignition, fuel system, or cooling. Key components will typically be labeled with part numbers, allowing you to easily cross-reference them with a parts list or manual for further details. Understanding these labels and their placement is vital for accurate identification during repairs.

Additionally, pay attention to the arrows and connections shown in the schematic. These often indicate how various parts are connected or interact with one another. Recognizing these relationships will help you understand the flow of energy, fuel, and exhaust through the system, making it easier to diagnose performance issues and maintain the engine’s efficiency over time.