When it comes to maintaining a home?s heating system, understanding the internal configuration and functions of its components is essential for effective troubleshooting and repair. A well-organized system relies on each element working in harmony, and having a clear view of its structure can significantly simplify maintenance tasks. Recognizing how different parts interact can also prevent costly repairs by addressing potential issues early on.

In this section, we will explore the critical elements that make up a typical heating unit. Knowing how these components fit together and function will empower you to identify problems and replace worn-out elements with ease. Whether you’re a novice or an experienced technician, a solid grasp of the system’s design is invaluable for ensuring the longevity and efficiency of your equipment.

Understanding Heating System Components

A heating system is made up of several interconnected elements that work together to provide warmth and comfort. Each component has a specific function, from air circulation to heat generation and distribution. Understanding the roles of these individual parts can help identify potential issues and streamline the repair process when problems arise.

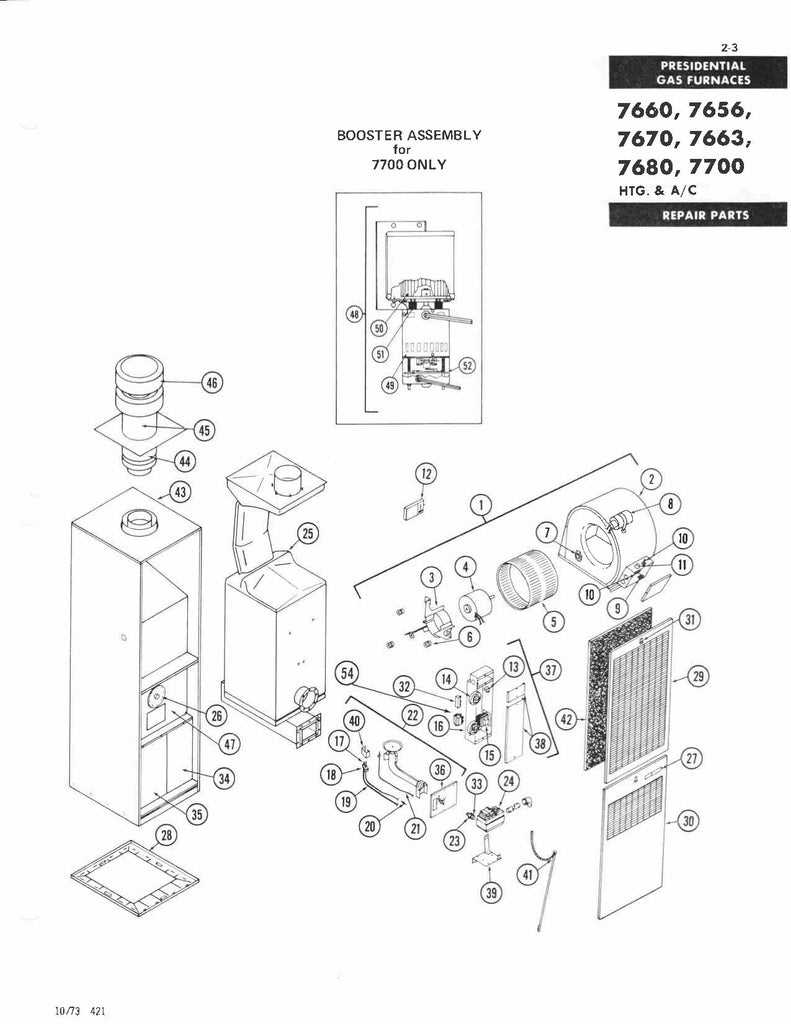

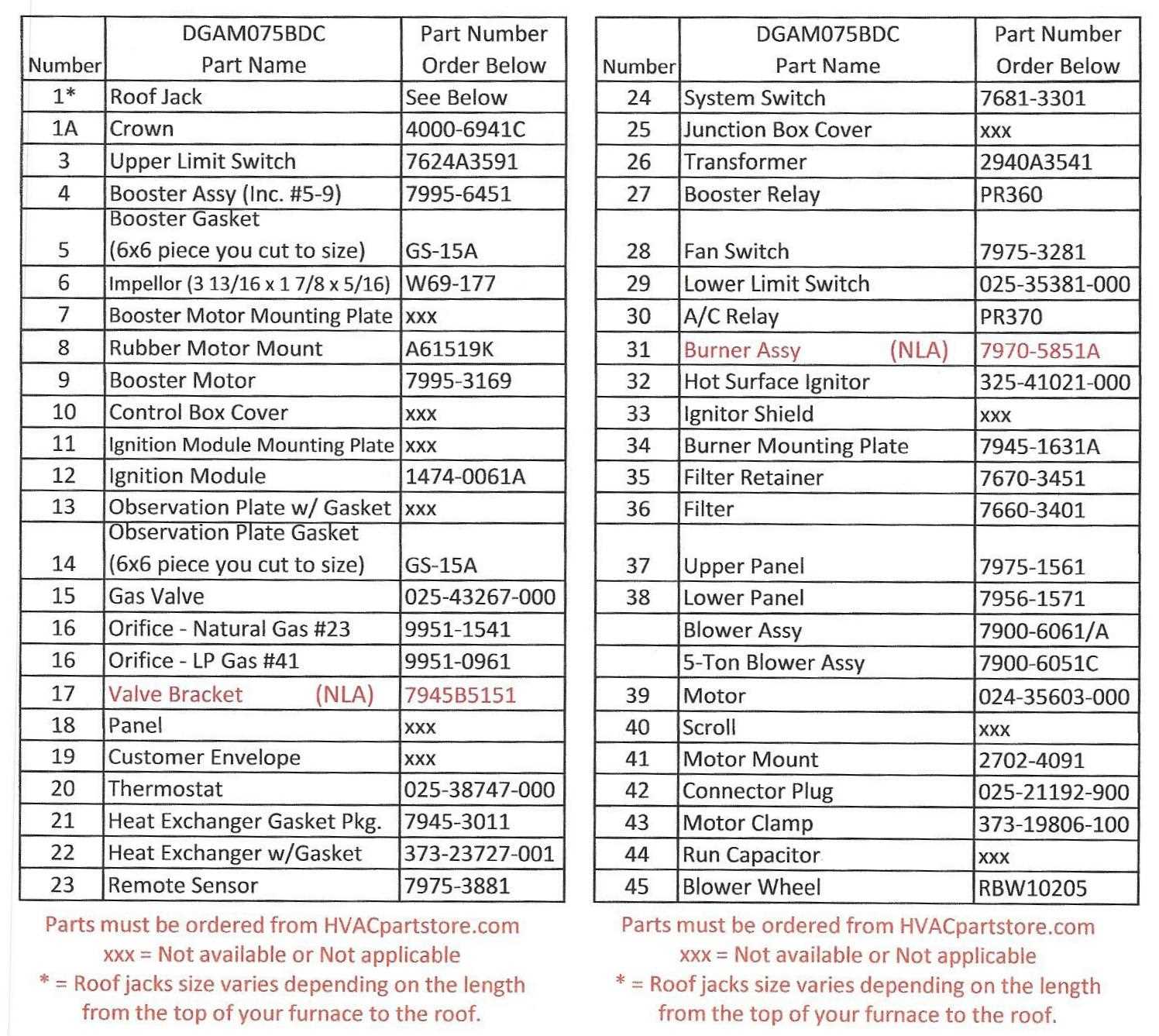

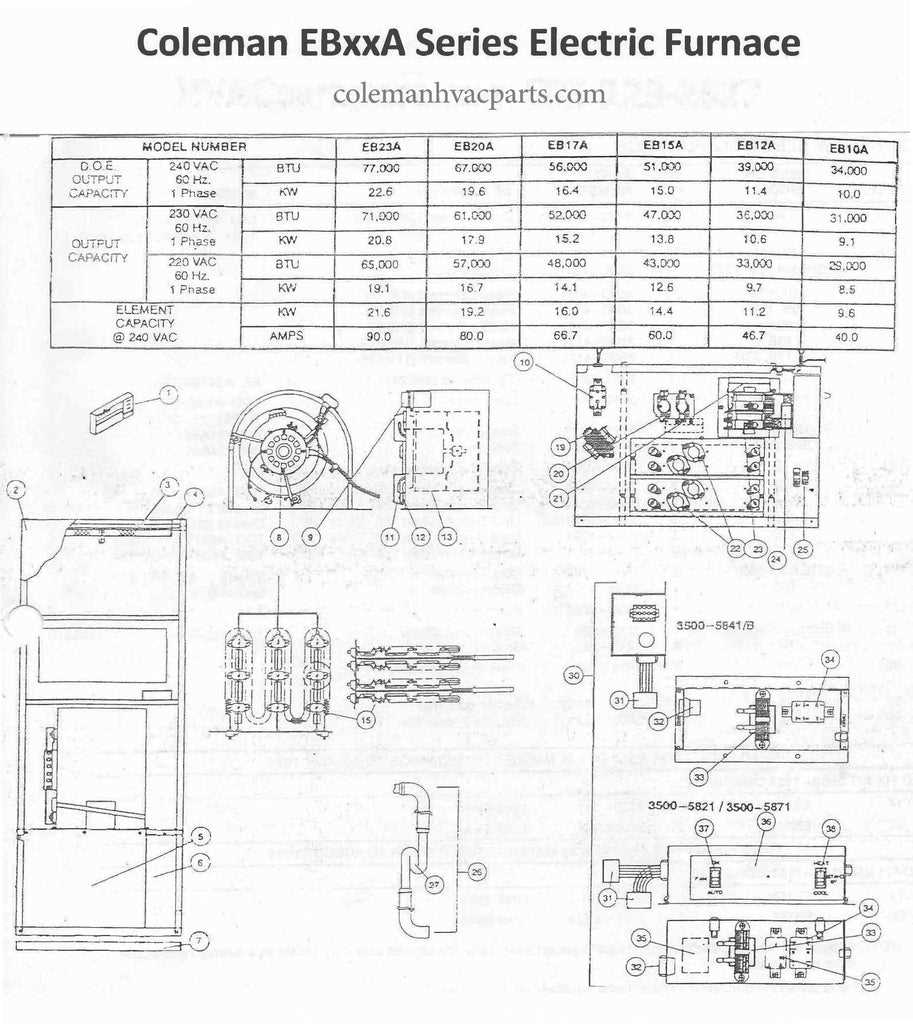

Key components include the ignition system, the blower motor, heat exchangers, and safety mechanisms. The ignition system ensures the proper start of the heating cycle, while the blower motor helps circulate warm air throughout the space. The heat exchanger is responsible for transferring heat to the air, and safety mechanisms monitor for any irregularities, ensuring the system operates safely and efficiently.

Familiarity with these critical elements allows for a more effective approach to maintenance and repair. Knowing how each part interacts with the others can simplify troubleshooting, helping you identify faults faster and with greater accuracy. With a clear understanding, you can enhance the overall performance and longevity of your heating system.

Common Issues in Heating System Components

Over time, the various components of a heating unit can experience wear and tear, leading to performance issues. Recognizing the most common problems is key to diagnosing and resolving faults quickly. Many of these issues are related to either mechanical failure or improper functioning of electrical and safety systems.

One common problem is a malfunctioning blower motor, which can result in insufficient air circulation or complete airflow failure. A dirty or clogged air filter can also hinder the system?s efficiency, causing it to overheat or work harder than necessary. Another frequent issue involves the ignition system, which can fail to start, often due to electrical malfunctions or faulty sensors.

Additionally, heat exchangers can develop cracks over time, leading to potential safety hazards. Leaks or blockages in gas lines or ventilation systems can compromise performance and pose a significant risk. Understanding these typical issues allows for better preparation and more efficient solutions during routine maintenance or when repairs are necessary.

Step-by-Step Repair and Replacement Guide

When facing issues with a heating system, performing repairs or replacing faulty components can seem daunting. However, following a structured approach can make the process more manageable and ensure the system continues to run smoothly. This guide provides a step-by-step method for identifying problems, replacing damaged components, and getting your system back to optimal performance.

Start by turning off the power and gas supply to the unit to ensure safety during the repair. Next, locate the malfunctioning component by observing symptoms such as unusual noises or inadequate heating. Once the issue is identified, carefully remove any covers or panels to access the affected area. If you’re replacing a part, ensure the new component matches the specifications of the old one.

After the new part is installed, reconnect everything and perform a test run to confirm that the issue is resolved. It?s important to check for any leaks, unusual sounds, or malfunctions before finishing the job. Regular maintenance, such as cleaning filters and checking safety mechanisms, can also prevent future issues and extend the lifespan of the system.