When working with any complex machine, having a clear overview of its essential elements is crucial for proper maintenance and repair. Knowing the arrangement and function of individual components ensures smooth operation and minimizes the risk of malfunction. A detailed map of the internal structure helps both beginners and experienced users tackle issues efficiently.

Efficiently identifying parts is fundamental when it comes to troubleshooting and ensuring that everything is in working order. Understanding the layout allows you to pinpoint which sections need attention, whether it?s routine maintenance or resolving a specific problem. Clear visualization plays a major role in preventing unnecessary confusion and saving time.

Through a thorough breakdown of these components, you can enhance your skills and gain confidence in handling the machinery. With the right knowledge, you?ll be able to address problems with ease and ensure that your equipment stays in top condition for a long time.

Understanding the Key Components

Every machine is a collection of interconnected parts, each serving a specific role in ensuring smooth and efficient operation. By understanding how these elements work together, you gain the ability to maintain and repair your equipment more effectively. An in-depth knowledge of the individual components allows for more accurate troubleshooting and better decision-making when issues arise.

Essential Elements for Optimal Functionality

At the heart of any engine, the primary components are responsible for driving the overall performance. These include the mechanisms that control power delivery, airflow, and fuel management. Each of these parts plays a vital role in ensuring that the system operates as intended, maximizing efficiency and minimizing wear and tear.

How Proper Understanding Enhances Maintenance

Understanding the specific functions of each part enables users to perform more targeted maintenance. Regular checks on critical components reduce the likelihood of unexpected breakdowns and extend the lifespan of the equipment. By becoming familiar with these internal elements, you can identify potential issues early and take proactive steps to address them, ensuring the continued reliability of your machine.

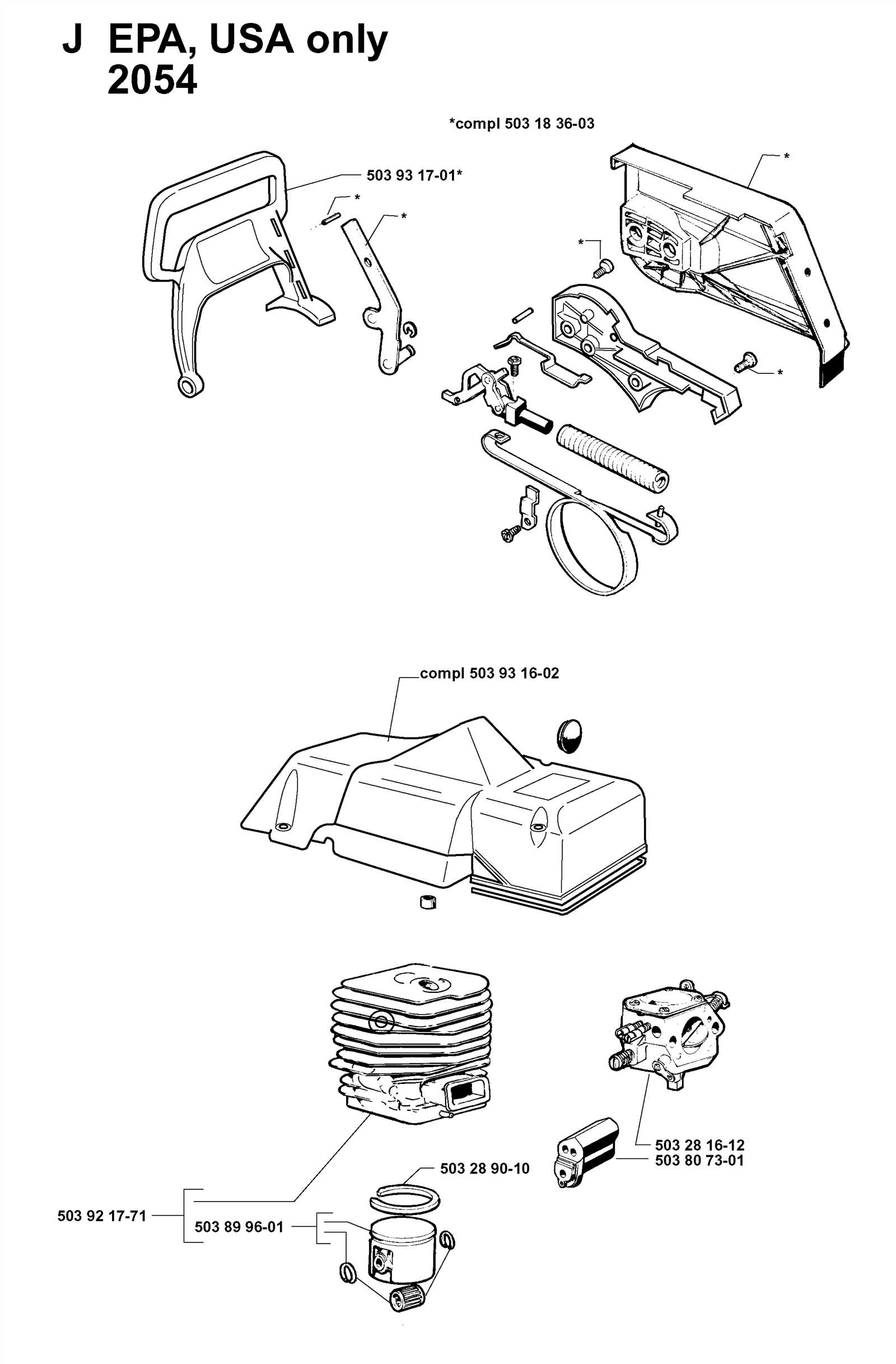

How to Use the Parts Diagram Effectively

A well-organized visual guide is invaluable when it comes to understanding the structure of any complex machine. It provides a clear map of all essential components, helping users identify their function and position within the system. By utilizing this guide correctly, you can save time, reduce errors, and ensure more efficient repairs or maintenance.

Identifying Key Components with Ease

The primary advantage of such a reference is its ability to show the relationship between different parts. It simplifies the process of locating individual elements within the machinery, ensuring that users can quickly find and inspect specific components. This not only speeds up repairs but also helps in identifying which areas might need attention without unnecessary disassembly.

Improving Maintenance Efficiency

By frequently consulting the guide during maintenance tasks, you can stay organized and ensure all steps are followed accurately. It provides clarity on the proper arrangement and positioning of parts, making reassembly straightforward. With regular use, the guide becomes a reliable tool that enhances overall operational efficiency and reduces the risk of mistakes.

Key Parts and Their Functions

Understanding the essential components of any piece of equipment is critical for proper maintenance and performance. Each element within the machine plays a specific role that contributes to its overall functionality. A clear understanding of these parts enables you to troubleshoot, perform repairs, and ensure the smooth operation of the system.

Power Delivery Mechanisms are at the core of the machine’s operation. These components are responsible for converting energy and delivering it to the necessary systems. They ensure that power is efficiently transferred, enabling the machine to perform its tasks with minimal energy loss.

Fuel and Air Systems are crucial for maintaining the balance between combustion and efficiency. These parts regulate the flow of fuel and air into the engine, ensuring optimal performance while preventing damage caused by irregular flow or blockages.

Control Systems govern how the machine responds to user input. These components control various actions, such as speed or power adjustment, and are vital for ensuring that the equipment operates smoothly and safely under different conditions.