In order to maintain and repair any firearm, it’s crucial to have a comprehensive understanding of its individual components. This knowledge ensures that each part functions properly and can be easily identified when needed. By grasping the layout and roles of the various elements, you’ll be better equipped to address any issues that may arise during routine use or restoration projects.

Recognizing each piece is an essential step in becoming proficient with the rifle. Whether you are a collector, a military enthusiast, or someone working on repairs, being able to identify and understand the specific role of each component will improve your overall experience. A clear grasp of how these pieces work together will enhance your ability to troubleshoot and perform necessary repairs with ease.

To assist in this process, we’ll explore the essential components of the M1 rifle in detail. Knowing how these parts are assembled and how they interact with one another is key to mastering the weapon’s functionality and ensuring its longevity.

Understanding M1 Carbine Components

Each firearm is made up of various essential elements that work together to ensure smooth operation and reliability. For anyone working with or restoring the M1, recognizing the function of every individual piece is critical for maintenance and repairs. Gaining insight into how each part contributes to the overall performance can greatly enhance your understanding of the weapon’s design and mechanics.

Key Functional Elements

The rifle consists of key functional elements that include the action mechanism, barrel, trigger assembly, and the stock. These components interact in a specific sequence to ensure the rifle performs effectively. Understanding how these parts fit together and their roles will help when troubleshooting or assembling the rifle. Each element’s position and alignment are vital for the proper operation of the weapon.

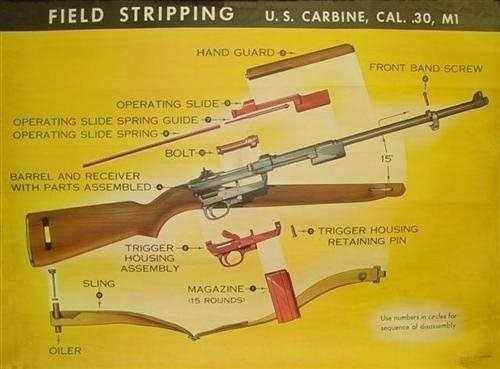

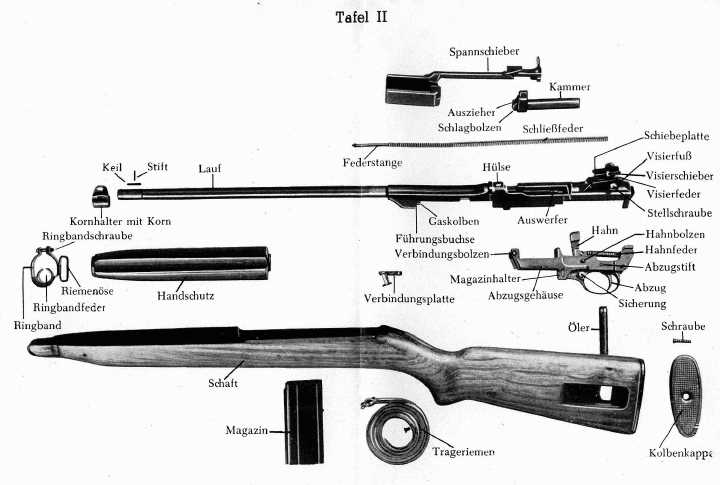

Assembly and Disassembly Process

Knowing how to properly assemble and disassemble the weapon is equally important. When broken down, it is much easier to inspect, clean, and replace any worn or damaged pieces. The process involves removing the stock, separating the trigger assembly, and carefully handling the internal mechanism. Mastering this procedure can prevent accidental damage and ensure that every part is correctly positioned for use.

How to Identify M1 Carbine Parts

Properly identifying each element of the rifle is a key step in maintaining its functionality. Being able to distinguish between various components allows for easier maintenance, repairs, and upgrades. Familiarity with the distinct characteristics of each piece will help ensure that everything is in its proper place and functioning correctly.

Visual Characteristics

Each component has unique features that make it identifiable. For example, the trigger assembly is easily distinguished by its specific shape and size, while the action mechanism is recognized by its position and method of operation. Understanding these visual markers is crucial for anyone working with the rifle, whether for restoration or general upkeep.

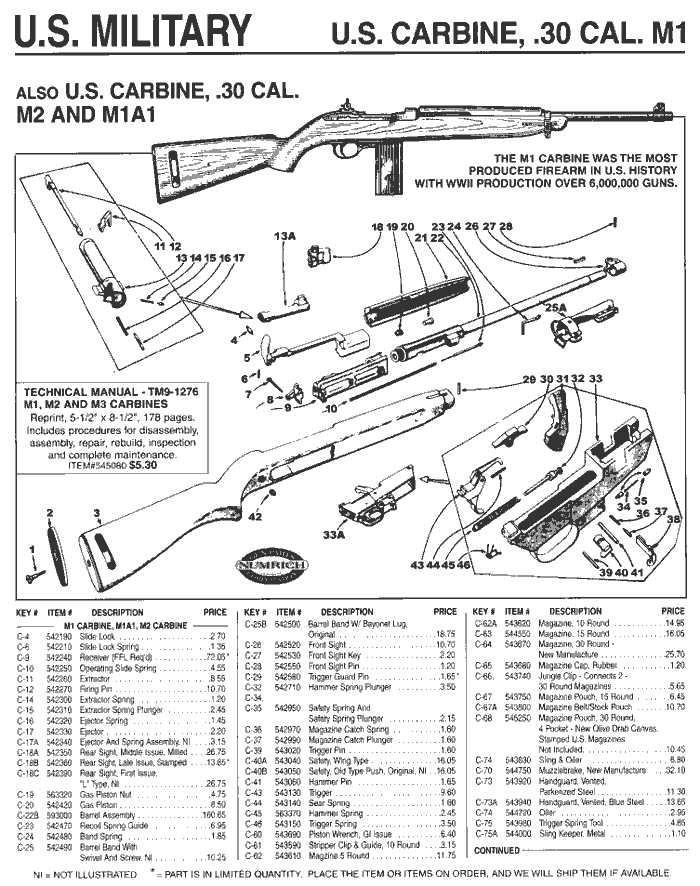

Markings and Serial Numbers

Many components feature markings or serial numbers that can aid in identification. These identifiers may be stamped or engraved onto the metal parts and often provide information about the manufacturer, model, and production date. Recognizing these markings can help in ensuring the correct part is used during repairs or replacement, preserving the rifle’s integrity.

Tips for M1 Carbine Maintenance

Regular upkeep is essential to keep any firearm functioning optimally. Proper care not only ensures reliability but also prolongs the lifespan of the weapon. Routine maintenance practices, such as cleaning and inspecting critical elements, are key to preventing malfunctions and wear.

First and foremost, always make sure the weapon is unloaded before beginning any maintenance tasks. Clean the internal mechanism thoroughly after each use, paying special attention to areas where carbon build-up can occur, such as the barrel and gas system. Using the right tools and lubricants can also prevent unnecessary friction that may cause premature wear on moving components.

Additionally, inspect all components for signs of damage or wear, especially those that are subject to regular stress, such as the trigger assembly and recoil springs. Replacing worn elements as soon as they are identified will ensure the rifle remains in peak condition for long-term performance.