In any equipment used for abrasive cleaning, knowing its key components is crucial for optimal performance. Each part plays a specific role in the overall function, ensuring efficiency and reliability. Without a proper understanding of these elements, maintenance and troubleshooting can become challenging.

Identifying the critical elements of such a system allows users to quickly address issues and ensure the equipment operates smoothly. From controlling the flow of material to providing the necessary power, each section is integral to the device’s success.

Properly examining these components regularly can prevent wear and tear, improving the lifespan of the equipment. Understanding their function not only aids in resolving problems but also enhances the user’s ability to perform necessary maintenance effectively.

Understanding Sandblaster Components

Every abrasive cleaning machine is composed of various key elements that work together to achieve the desired outcome. Each component plays a distinct role in ensuring that the system operates efficiently and consistently. Understanding these parts helps users maintain the equipment and identify potential issues before they disrupt the cleaning process.

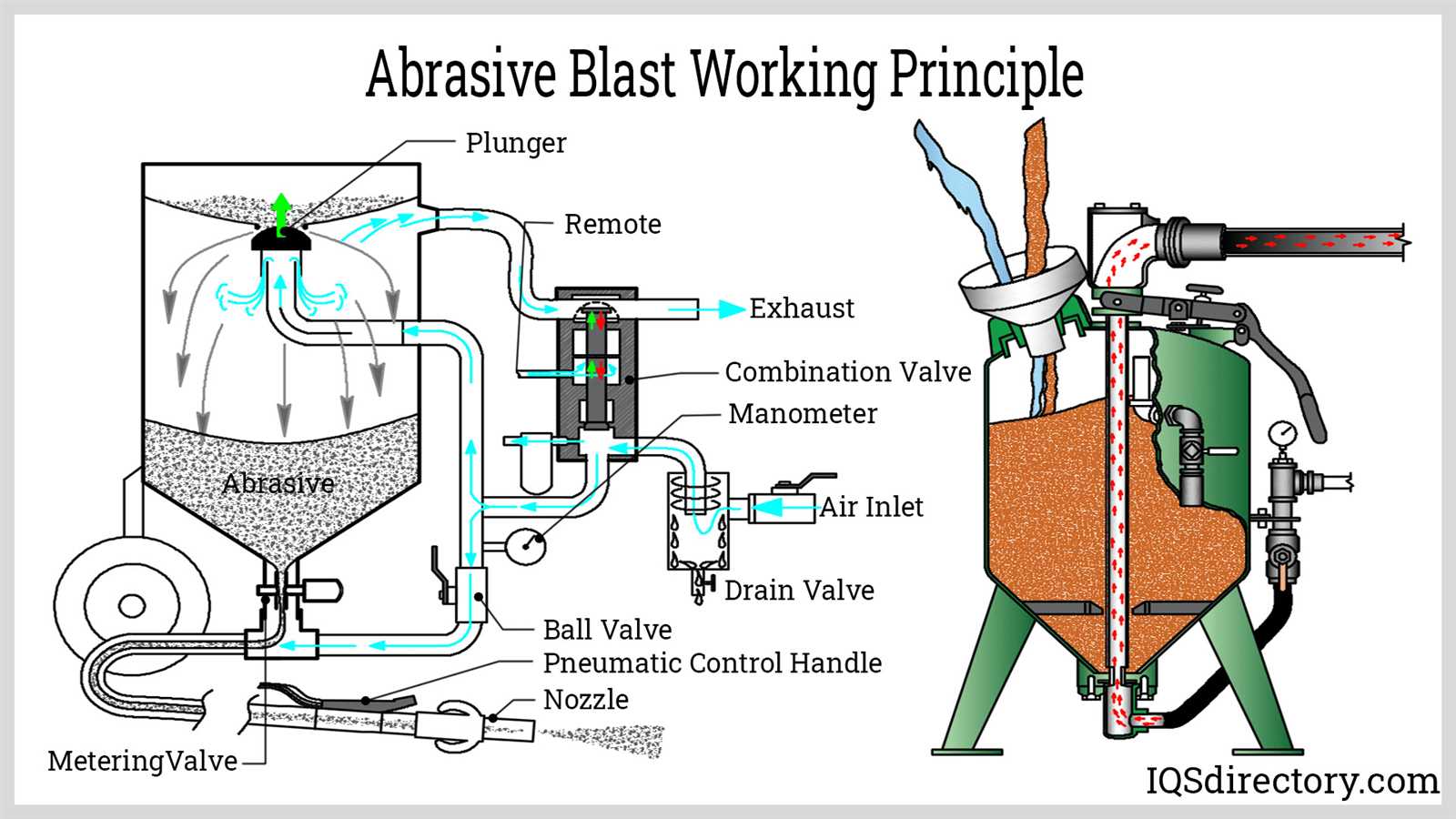

One of the primary components is responsible for regulating the flow of the abrasive material. This element ensures that the right amount is delivered for effective cleaning. Another crucial part manages the pressure and velocity of the air or fluid, which is vital for controlling the cleaning process. The design and functionality of these elements are fundamental to the overall performance and longevity of the machine.

Regular inspection and awareness of how each part contributes to the system allow for more efficient troubleshooting and maintenance. A deep understanding of these essential components can lead to better decision-making regarding repairs and upgrades, ensuring that the equipment continues to meet operational needs for an extended period.

Key Parts and Their Functions

In any abrasive cleaning system, several critical elements are responsible for ensuring smooth and efficient operation. These components work together to control the flow, pressure, and application of the cleaning material. Each section is vital for achieving the desired results and maintaining overall performance.

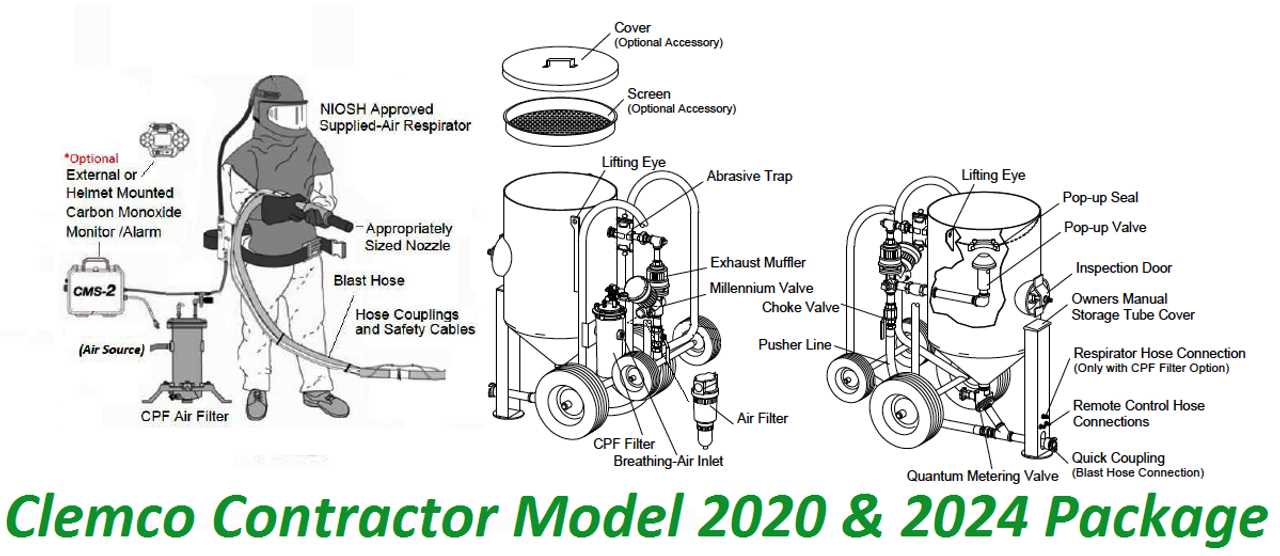

The control valve is one of the most important features, as it regulates the release of the abrasive material, allowing the user to adjust the flow based on the task. The pressure regulator ensures that the system maintains consistent air or fluid pressure, optimizing performance and preventing damage to other components. Additionally, the nozzle plays a crucial role in directing and controlling the flow of the material for precise application.

Other parts, such as the air compressor and the hose, work in tandem to provide the necessary power and delivery system for the cleaning process. Understanding the function of each of these components enables users to troubleshoot problems, perform effective maintenance, and ensure that the system operates at its full potential.

How to Identify Sandblaster Issues

Recognizing problems in an abrasive cleaning system is essential for preventing costly repairs and downtime. By understanding the typical signs of malfunction, users can quickly identify what might be causing inefficiencies or failures. Proper troubleshooting begins with knowing what to look for and how to address each issue effectively.

One common issue is irregular or low material flow, which could indicate a blockage in the delivery system or a malfunctioning valve. If pressure levels seem inconsistent, it may point to issues with the regulator or the air supply. Additionally, poor cleaning results could signal a problem with the nozzle or the air-to-material ratio.

Regularly checking for wear and tear on the components, such as cracks or leaks, is another key step in identifying potential problems. Once an issue is detected, performing a thorough inspection of the relevant components will help pinpoint the exact cause, allowing for faster and more accurate repairs.