Every mechanical tool is built from various elements, each playing a crucial role in ensuring its efficiency and longevity. Understanding how these components work together can greatly enhance your ability to maintain and repair the device when needed.

Identifying the correct components is essential for anyone looking to perform repairs or upgrades. Whether you’re a professional or a hobbyist, having a clear understanding of how everything fits together will save time and improve performance.

In this section, we will explore the most important elements, providing a clear breakdown to help you familiarize yourself with their functions and connections. Knowing what each part does will enable you to take better care of your equipment.

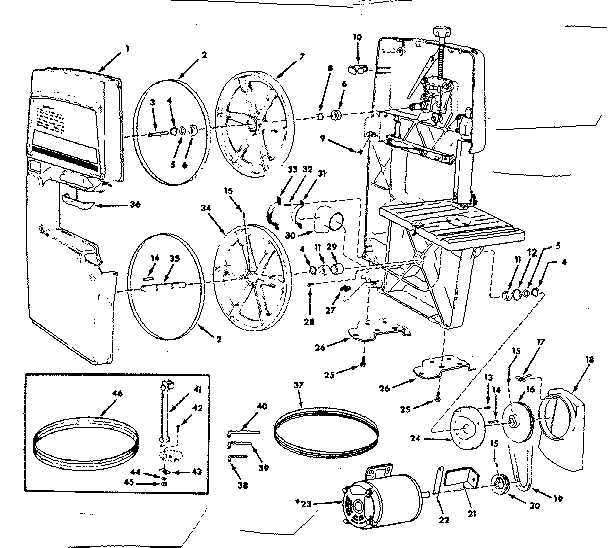

Craftsman 12 Inch Band Saw Overview

Tools designed for cutting wood and other materials are essential for precision and efficiency in various workshops. These devices are often equipped with specific features that enhance their versatility and usability. A deeper understanding of their key aspects is crucial for anyone using them regularly.

To ensure maximum functionality, it is important to become familiar with the core features and capabilities. Recognizing the different elements allows users to perform maintenance or troubleshooting more effectively.

- Design and Build – A solid framework and quality construction materials provide long-lasting durability and performance.

- Cutting Power – Equipped with a powerful motor, these devices can handle a wide range of cutting tasks.

- Adjustability – Flexible settings make it easier to adapt the device to different tasks and material types.

Understanding these features not only helps in maximizing the tool’s potential but also ensures safety and efficiency during operation. Proper care and knowledge lead to better results and extended service life for any machine.

Understanding the Key Parts of a Band Saw

Every cutting tool is made up of several important components that work together to ensure efficient and safe operation. Recognizing these elements and how they function will make it easier to maintain and troubleshoot the equipment. Knowledge of these key parts allows for better performance and longer tool life.

Some of the most crucial components include the motor, tensioning system, and guiding mechanism. Each part has a specific function that contributes to the overall effectiveness of the tool. Proper care and understanding of these elements can prevent issues and ensure optimal use.

By becoming familiar with the layout and operation of each part, users can troubleshoot problems quickly and replace worn-out components when necessary. Regular inspection of these elements helps in identifying potential issues before they cause significant damage.

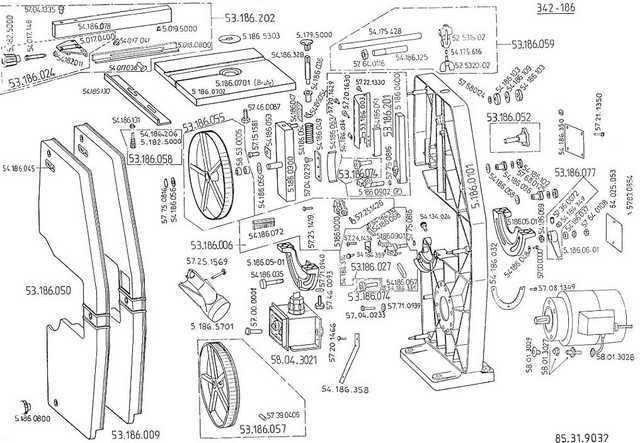

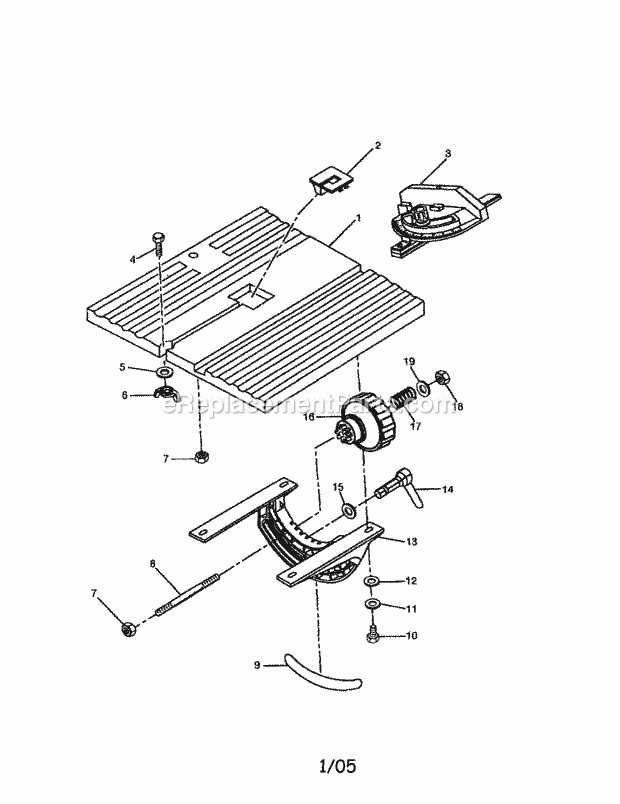

How to Read a Parts Diagram

Understanding how to interpret the layout of a tool is essential for anyone looking to perform repairs or upgrades. A visual representation of a tool’s components can provide a clear overview of how each piece fits together, helping users quickly locate issues or identify parts that may need replacement.

Key Elements of a Diagram

The diagram typically includes labeled sections that correspond to various components of the device. Each element is marked with a unique identifier, allowing users to match the physical part with its label for easier identification and ordering.

How to Use the Information

Once you understand the layout, you can use the diagram to guide maintenance and troubleshooting. Checking the diagram regularly ensures you’re aware of the tool’s structure and can spot any signs of wear or malfunction in the various components.

Maintenance Tips for Band Saw Components

Regular upkeep of essential tool components is vital for maintaining performance and extending the lifespan of your equipment. By following simple maintenance practices, you can prevent unnecessary breakdowns and ensure consistent results during operation.

Cleaning and Lubrication

Keeping the key parts clean is crucial for smooth operation. Dust and debris can accumulate, affecting the tool’s functionality. Regular cleaning, followed by lubrication of moving parts, helps reduce friction and ensures optimal performance.

Inspecting for Wear and Tear

Routine checks for signs of wear are essential for detecting issues before they become major problems. Pay attention to components that undergo heavy use, such as the tensioning system and motor, to ensure they remain in good condition and replace any parts that show significant wear.