When it comes to maintaining and repairing industrial machinery, having a clear visual representation of its internal structure is essential. This tool can help you identify every component, making repairs or upgrades more manageable and less time-consuming.

Knowing how to interpret the layout of the various parts enables you to understand how each piece works together, improving efficiency and preventing potential malfunctions. A well-detailed schematic is indispensable for technicians and users alike.

By familiarizing yourself with the layout and common issues, you can make informed decisions about maintenance and repairs. This guide will provide insights into the key elements of your equipment, ensuring it runs smoothly for years to come.

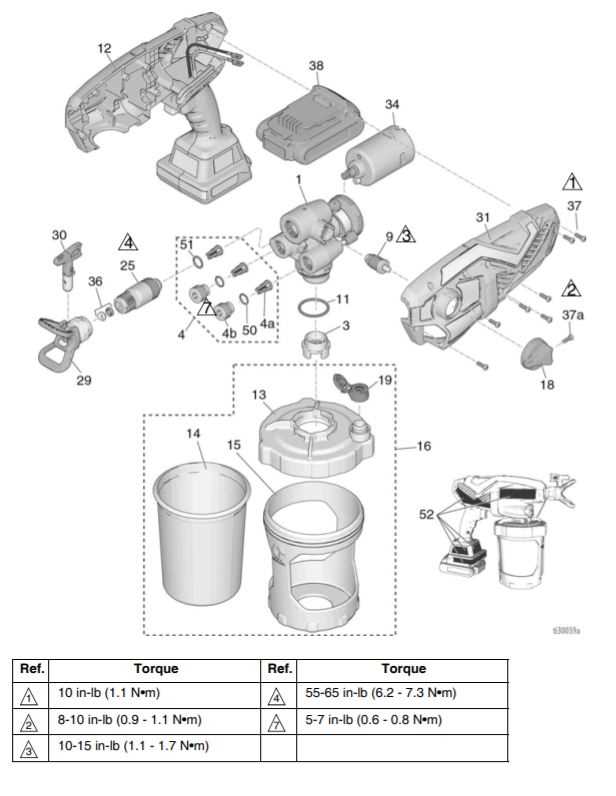

Understanding Graco RTX 2000 Components

In any complex mechanical system, each individual element plays a crucial role in ensuring the overall functionality of the machine. Familiarity with these elements is essential for proper operation, repair, and troubleshooting. Knowing how the different sections and components interact can greatly simplify the process of maintaining the equipment and extending its lifespan.

The key components within the system are designed to work in harmony, with each part contributing to specific functions such as fluid delivery, pressure regulation, and mobility. Understanding their relationships will allow users to diagnose issues effectively and make informed decisions regarding replacements or repairs.

By closely studying the assembly and identifying potential weak spots, it becomes easier to recognize when something is malfunctioning. This knowledge empowers users to act quickly, ensuring minimal downtime and optimal performance. Recognizing common wear points and potential problems before they escalate is a significant advantage in maintaining operational efficiency.

How to Read the Parts Diagram

Interpreting a schematic is an essential skill for understanding the inner workings of any mechanical system. It allows users to identify each individual component and their specific function within the assembly. Knowing how to navigate the visual representation of a machine can greatly enhance troubleshooting, repairs, and maintenance efforts.

Identifying Key Elements

When viewing the schematic, the first step is to locate the key components. Each part will typically be labeled with a unique identifier, such as a number or letter, which corresponds to a list of descriptions. This reference list is essential for understanding what each part does and how it fits into the larger system.

Understanding Relationships Between Components

Once you’ve identified the individual components, the next step is to understand their interconnections. Arrows or lines usually indicate how parts interact with each other. Recognizing these connections can help you understand the flow of materials or energy and identify potential points of failure.

Common Issues and Solutions for Graco RTX 2000

Every complex machine is prone to encountering occasional problems, and understanding these issues can help users respond effectively. By familiarizing yourself with common malfunctions, you can take preventive measures and resolve problems quickly, minimizing downtime and enhancing performance.

Low Pressure or Inconsistent Flow

One of the most frequent issues faced is low pressure or uneven fluid flow. This can be caused by clogged filters, worn seals, or air trapped in the system. To resolve this, check the filters and replace them if necessary. Bleed the system to eliminate trapped air, and inspect the seals for signs of wear and tear.

Unusual Noises or Vibrations

Another common problem is unusual noises or vibrations during operation. This is often a result of loose components or misalignment in the system. Tighten any loose bolts or connections and ensure that all parts are aligned properly. If the noise persists, inspect for worn bearings or other mechanical issues that may require replacement.