Maintaining outdoor tools requires a solid understanding of their individual components. Knowing how each part fits together and functions helps in diagnosing issues and performing repairs efficiently. Whether you’re repairing a lawn care machine or another tool, the assembly process is crucial for ensuring smooth operation.

Each machine is made up of various sections, from the motor to the exhaust. Understanding how these parts interconnect allows for easier troubleshooting and effective maintenance. This knowledge is also essential when replacing worn-out parts or upgrading specific sections of your equipment.

In this guide, we will explore the key components, how to identify them, and provide a detailed look at their role in the overall function of your tool. By the end, you will be better equipped to tackle repairs and keep your equipment running at peak performance.

Understanding Equipment Components

Every outdoor power tool is designed with a series of interconnected elements, each playing a vital role in the overall performance. Whether you are troubleshooting an issue or performing routine maintenance, having a clear understanding of these components is crucial. Familiarizing yourself with how each part contributes to the functioning of the tool ensures that repairs are done correctly and efficiently.

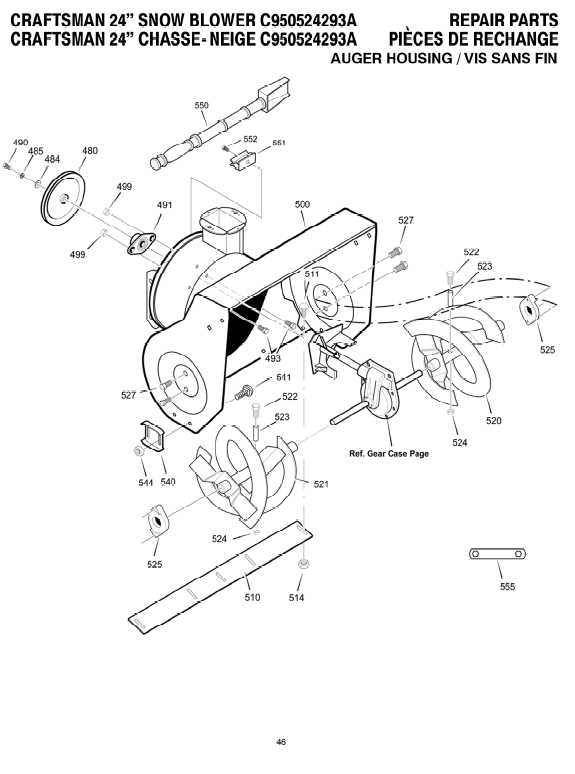

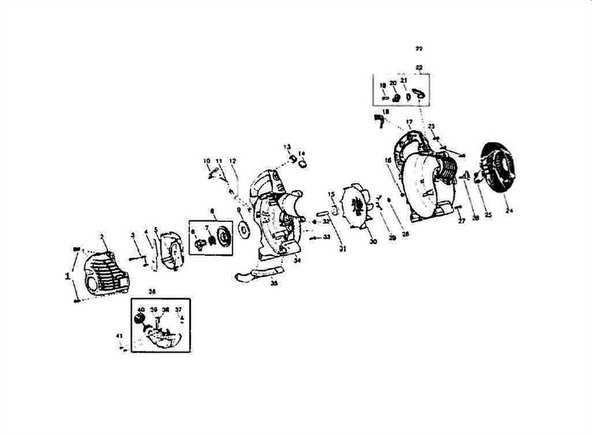

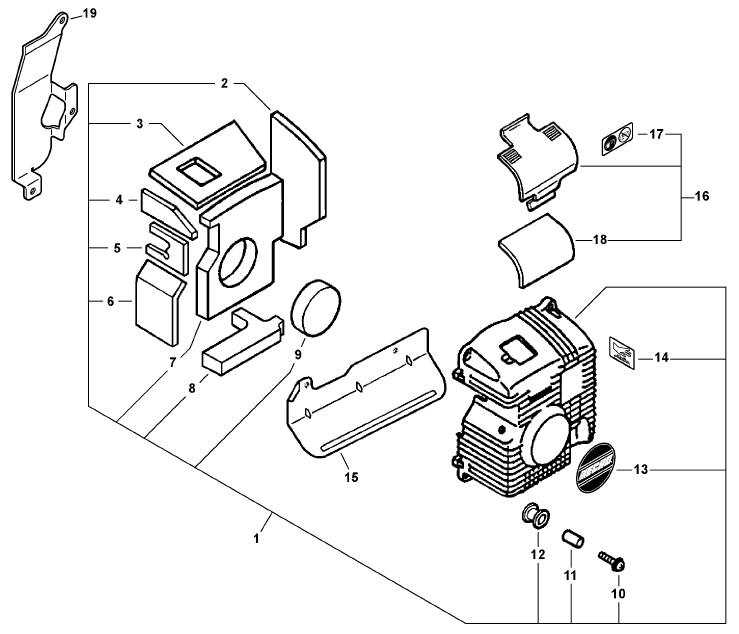

Key Components of the Tool

The main sections of your equipment include the power source, airflow system, and operational controls. Understanding the role of each section can significantly improve the repair process. Below are the primary elements that make up the tool:

- Motor: Powers the device and drives the operation of other components.

- Airflow system: Includes the fan and intake components responsible for generating air movement.

- Exhaust: Facilitates the release of air and other gases after processing.

- Controls: Allow users to adjust the settings of the machine for various tasks.

Importance of Proper Assembly

Proper assembly of these components is essential for efficient operation. Any disruption in their alignment or connection can lead to reduced performance or failure. It’s important to follow assembly instructions carefully and ensure that each part is secured in place. Regular maintenance helps prevent issues like wear and tear, keeping your tool in top working condition.

Identifying Common Equipment Components for Repair

When performing maintenance or repairs on your outdoor tool, identifying the right components that need attention is essential. Each section plays a distinct role in the machine’s functionality, and recognizing common issues with these parts will guide you through the repair process. Familiarizing yourself with the most frequently replaced or repaired elements ensures that the tool continues to perform optimally.

Commonly Replaced Elements

Several components tend to experience wear over time, leading to decreased performance or malfunction. These are typically the parts that require attention most often:

- Fan blades: Often subject to damage from debris or wear, affecting airflow and performance.

- Air filter: Prevents dirt and debris from entering the system, and can become clogged, reducing efficiency.

- Fuel lines: Over time, these can deteriorate or develop leaks, hindering fuel flow.

- Trigger mechanism: The main control used to operate the machine, which may wear down with repeated use.

Identifying Faults Early

It’s important to identify issues early to avoid further damage. Checking for loose connections, unusual sounds, or reduced performance can point to specific parts that need attention. Regularly inspecting your equipment for these common issues can save time and money on repairs in the long run.

Step-by-Step Guide to Equipment Assembly

Assembling your outdoor tool correctly ensures that all components function properly and work together efficiently. Following a clear, step-by-step process minimizes errors and helps avoid issues during use. This guide will walk you through the essential steps to properly assemble your equipment, ensuring smooth performance and durability.

Before starting, make sure you have all the necessary components and tools. Having everything in place will prevent delays and confusion during the assembly process. Follow these steps to ensure proper alignment and secure attachment of each part:

- Start with the base unit: Place the main body of the machine on a flat surface to ensure stability while assembling other components.

- Attach the motor or engine: Secure the motor in place, making sure all connectors are aligned and fastened tightly.

- Install the airflow system: Attach the fan blades and intake section, ensuring the air paths are clear of debris.

- Connect the controls: Install any switches or handles, ensuring they are in place for easy access and operation.

- Check for alignment: Once all parts are connected, verify that everything is aligned correctly and securely tightened.

After assembly, perform a test run to ensure everything is working as expected. If any issues arise, double-check the connections and verify that all parts are securely in place. Regular maintenance will help keep your equipment in optimal working condition over time.