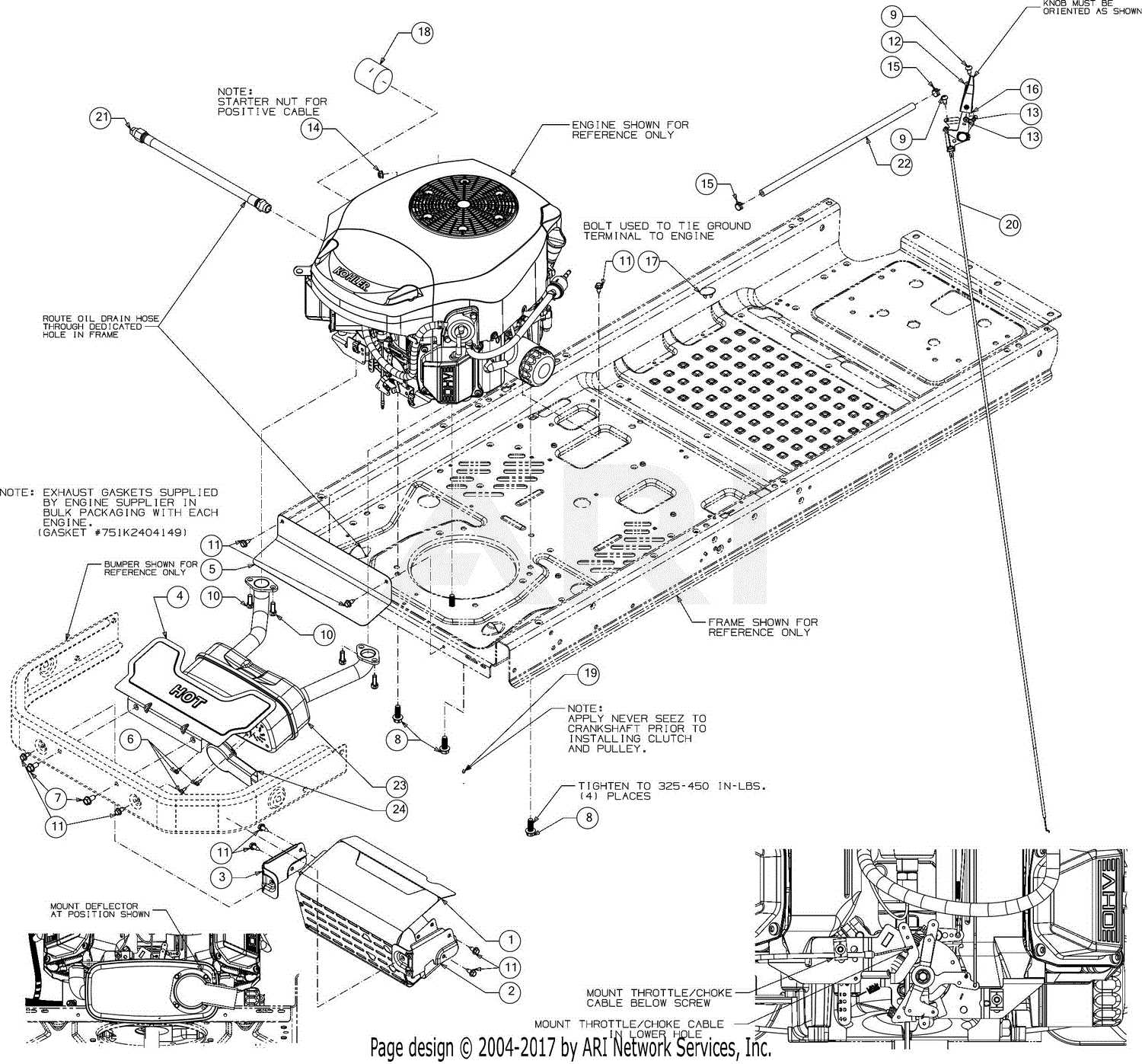

When maintaining or repairing your outdoor machinery, knowing the internal layout of the system is essential for efficient troubleshooting and replacement. Understanding the relationships between various components helps ensure a smoother process during maintenance and repairs. This knowledge is especially valuable when tackling complex equipment that requires detailed attention.

Visual guides are crucial tools in these situations, as they provide a clear map of all the essential parts and their connections. They can significantly enhance your ability to quickly identify potential issues, saving time and effort. Whether you are fixing a malfunction or performing regular upkeep, a well-structured visual reference offers clarity.

Additionally, familiarizing yourself with the essential elements of the equipment’s construction allows you to make informed decisions about repairs, reducing the likelihood of errors. Understanding how everything fits together empowers you to address specific challenges with confidence and precision.

Understanding the Mustang XP 50 Components

Knowing the key elements of any equipment is fundamental for maintaining optimal performance and ensuring smooth operation. Understanding the core components is crucial, as each plays a unique role in the overall function of the machine. When you are familiar with these components, it becomes easier to identify issues and take appropriate action to correct them.

Each major element of the system is designed to work in harmony with others. These components interact to ensure the machine operates efficiently. Recognizing the role of each piece, whether it’s for movement, power transmission, or other functions, allows for better maintenance and troubleshooting.

Regular familiarity with these parts helps in preventing unnecessary breakdowns. A solid understanding of how each part contributes to the machine’s operation gives you the ability to address potential malfunctions quickly and with minimal effort, enhancing your machine’s longevity and performance.

How to Use the Parts Diagram Effectively

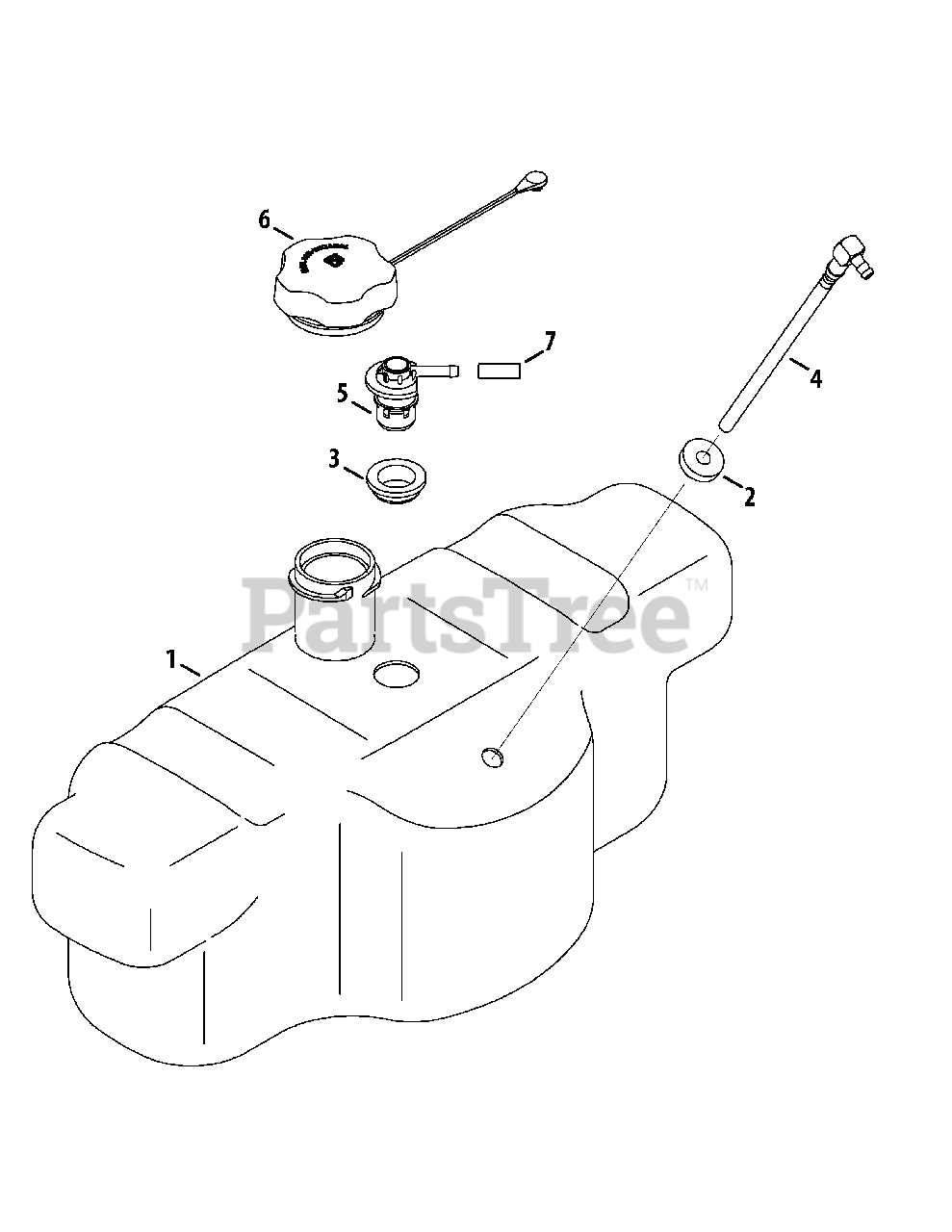

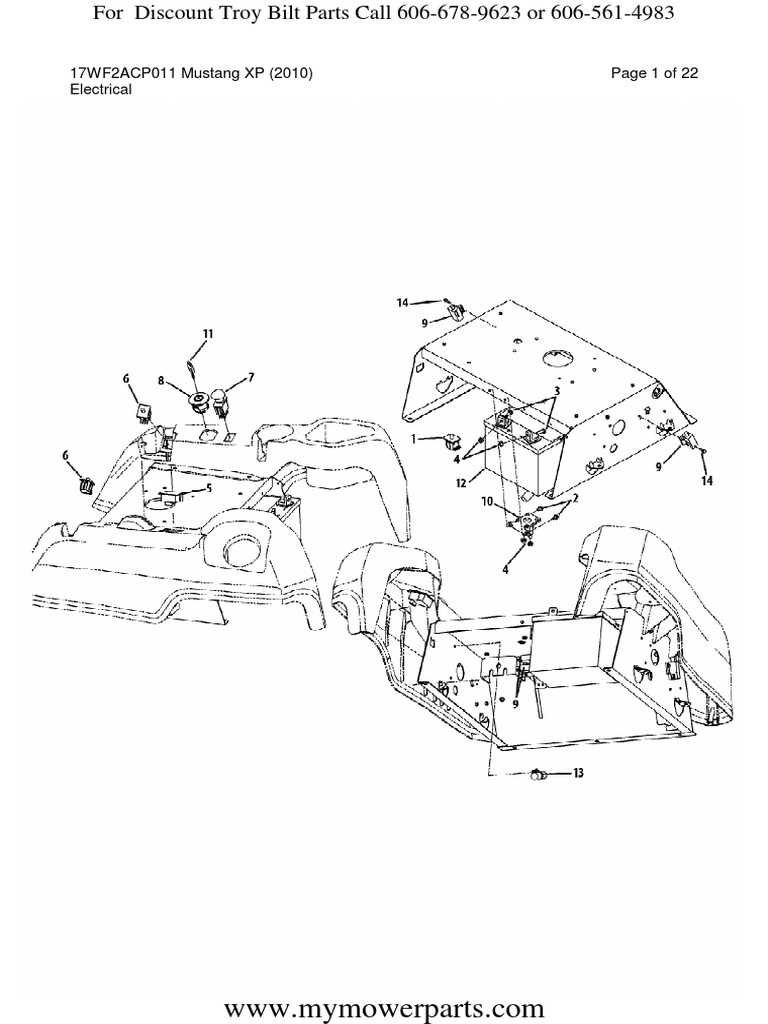

Utilizing a visual reference for your equipment is an essential tool when performing repairs or conducting routine maintenance. Understanding how to read and interpret these visuals can significantly streamline the process. By following a few steps, you can ensure that you’re using the guide to its full potential, helping you identify and fix issues efficiently.

Start with Familiarization

Before diving into any repair work, take some time to familiarize yourself with the layout. The visual guide will typically feature different sections, each representing a key area of the equipment. Take note of how these sections are labeled and how the components are connected. This initial overview will allow you to quickly locate specific parts when needed.

Follow a Systematic Approach

When using the reference during maintenance, always approach the task methodically. Identify the components that need attention and match them with their visual counterparts. Cross-check each part’s location and ensure its functionality. This careful step-by-step approach reduces the chance of overlooking critical details and ensures precision during repairs.

Common Repairs with Mustang XP 50 Components

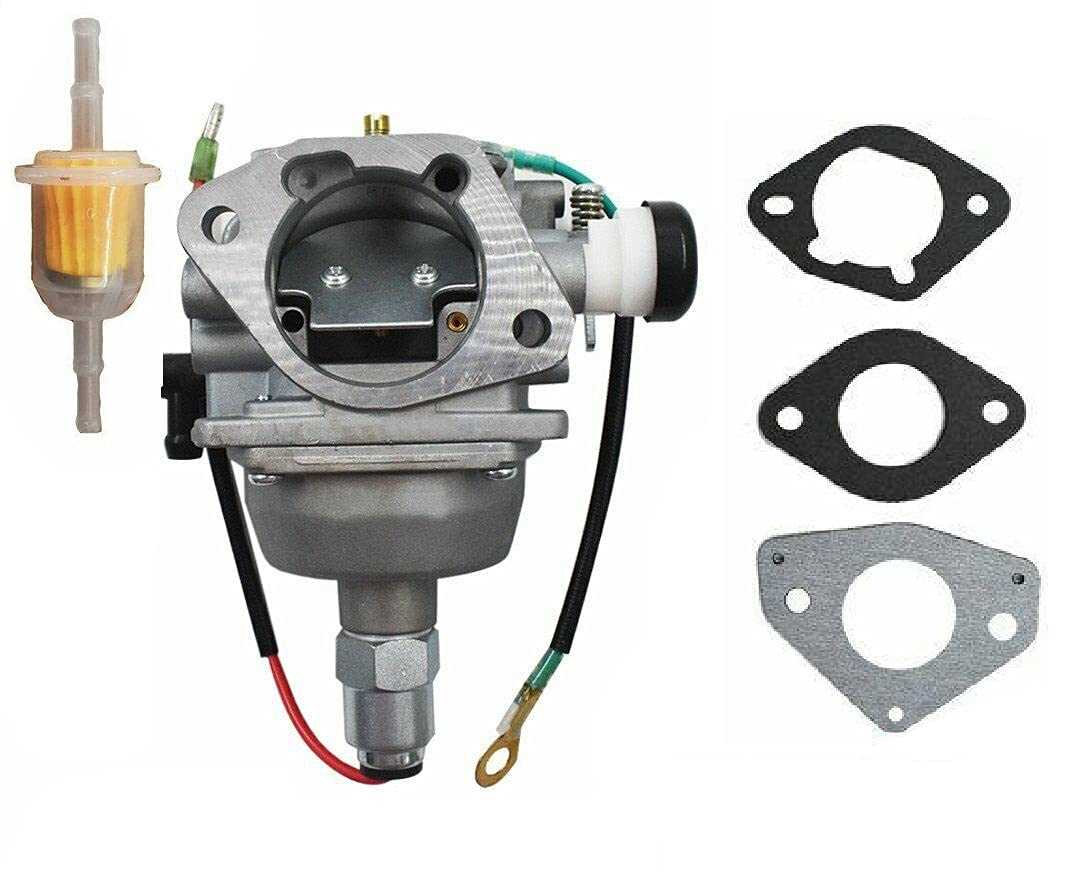

When maintaining outdoor machinery, several common issues may arise that require attention to specific elements. These challenges often involve components that wear out or get damaged during regular use. By recognizing the typical repairs needed for such equipment, owners can address these problems promptly, ensuring the machinery runs smoothly.

One frequent repair involves the transmission system, where wear and tear can lead to reduced performance. This could involve replacing damaged gears or checking the linkages to ensure everything is aligned. Another common issue is related to the engine components, such as spark plugs or filters, which may need to be replaced to maintain optimal power output.

Additionally, maintenance on the steering and braking systems is essential for safety and control. These components often require occasional adjustments or replacements to ensure they are responsive and functioning as intended. By regularly inspecting these critical elements, you can prevent further damage and extend the lifespan of your equipment.