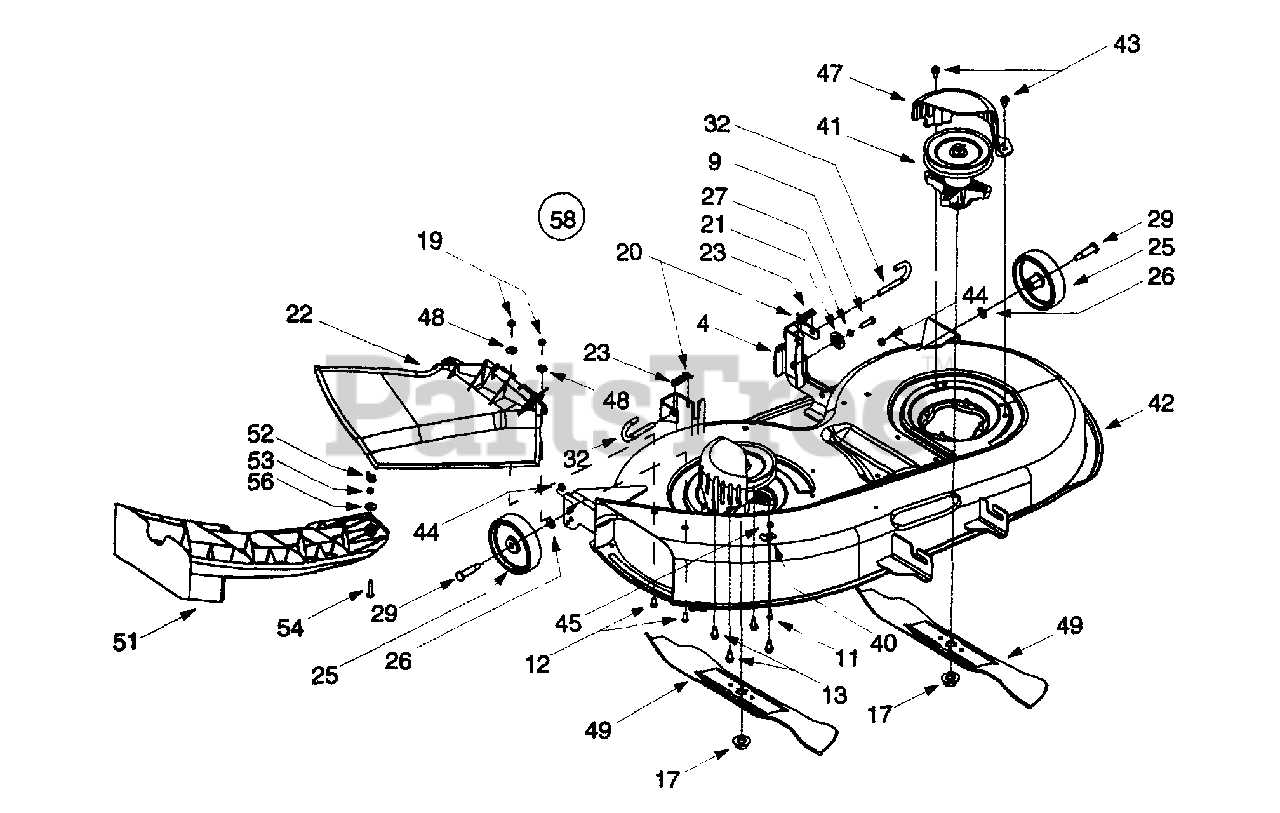

When it comes to maintaining outdoor machinery, understanding how each component works together is crucial for efficient repair and care. A clear visual representation of the parts and their arrangement can significantly improve your ability to troubleshoot and fix issues as they arise.

In this guide, we will explore the various elements that make up your machine, providing you with essential knowledge to identify and replace damaged or worn-out components. With the right reference materials, performing routine maintenance becomes a straightforward task.

Whether you’re tackling minor fixes or more complex repairs, having a detailed reference will help you save time and effort. Knowing where each part fits and how it functions ensures that your equipment stays in top working condition for years to come.

Understanding Craftsman DGS 6500 Components

Every piece of machinery is made up of multiple interconnected elements that work in harmony to ensure optimal performance. To effectively maintain or repair your equipment, it is essential to familiarize yourself with the specific components and their roles within the system. A deeper understanding of these parts helps you identify issues faster and take appropriate action before a minor fault turns into a major problem.

Key Components to Focus On

From the engine to the wheels, each part of the system serves a specific function. It’s crucial to pay attention to essential components like the transmission, steering mechanism, and the power source. Understanding how these parts interact with each other allows you to detect signs of wear or malfunction early on, ensuring the longevity and reliability of your machinery.

How Components Affect Overall Performance

Each component is designed to contribute to the overall efficiency of your equipment. For instance, the drivetrain ensures smooth movement, while the engine powers the entire system. If any part fails to perform correctly, it can have a cascading effect on the entire machine. Regular inspection and knowing the purpose of each element help you maintain a balanced system and prevent unnecessary breakdowns.

How to Use the Parts Diagram Effectively

Having a clear visual guide of your machine’s components can simplify the repair and maintenance process significantly. By studying this reference, you can identify each element, understand how they connect, and determine where potential issues may arise. Knowing how to navigate this visual guide ensures that you can quickly locate the part you need and make the necessary repairs or replacements without confusion.

When using a reference image, start by familiarizing yourself with the overall layout. Identify the key sections of the machinery, such as the engine or control system, and understand the flow of power and movement. This understanding will help you narrow down the specific area you need to address when an issue occurs.

Additionally, pay close attention to any labels or numbers associated with each part. These identifiers are crucial when searching for replacement components or understanding the relationship between different parts. With this approach, you’ll be able to resolve issues efficiently, ensuring your machine runs smoothly for an extended period.

Common Repairs for Craftsman DGS 6500

Even with regular maintenance, outdoor equipment may encounter problems that require repair. Understanding the common issues that arise with these machines helps you prepare for quick fixes and avoid prolonged downtime. From minor adjustments to more complex replacements, addressing these issues promptly can keep your equipment running smoothly for years.

Engine and Fuel System Issues

One of the most common areas that require attention is the engine and fuel system. Over time, the engine may suffer from poor performance due to clogged fuel lines, dirty air filters, or worn spark plugs. Regularly cleaning the fuel system and replacing parts like the air filter can prevent many issues, ensuring that the engine starts easily and runs efficiently.

Drive and Steering Components

Another area that may need frequent repairs is the drive and steering system. Components such as belts, pulleys, and steering linkages can wear out with continuous use. Inspecting these parts regularly and replacing worn-out components can restore the equipment’s movement and control, ensuring safety and efficiency during operation.