When working with power tools, understanding their internal components is crucial for efficient operation and long-term performance. Every machine is made up of several key elements that work together to provide precision and durability. Recognizing how these pieces function can help you troubleshoot issues and ensure proper maintenance.

Understanding the structure of your equipment allows you to identify wear and tear, replace damaged parts, and improve overall functionality. From motors to switches, each part plays a significant role in the machine’s performance.

In this section, we will break down the various parts of your tool, showing how each component fits into the bigger picture. Whether you’re a professional or a hobbyist, this knowledge is invaluable for keeping your equipment running smoothly and avoiding costly repairs.

Understanding Tool Components

Each tool is a complex system made up of various essential elements that work in harmony to achieve optimal performance. Whether it’s the motor, housing, or smaller mechanisms, each piece plays a critical role in ensuring smooth operation. Understanding these components allows for better handling, effective maintenance, and more informed repairs.

Main Functional Elements

The core components of the tool include the motor, drive system, and cutting mechanism. The motor generates power, while the drive system transfers this energy to the working parts. Understanding the interaction between these major elements helps in troubleshooting and identifying potential issues.

Minor Components and Their Roles

In addition to the main parts, various smaller elements such as springs, nuts, and bolts support the functionality of the tool. These components, although often overlooked, are crucial for stability and safety. Proper knowledge of these pieces ensures the tool remains in good working condition for a longer period.

How to Read a Components Layout

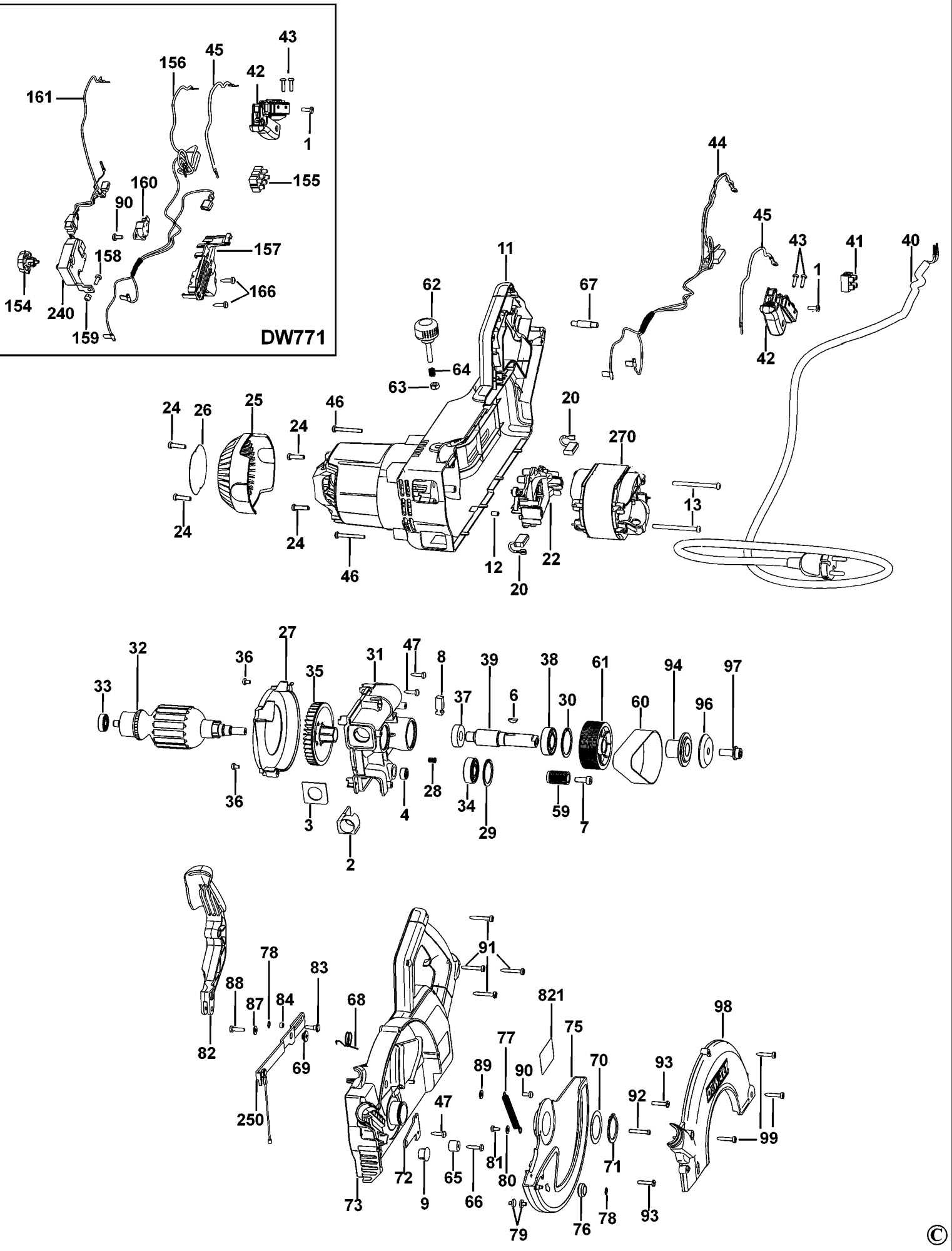

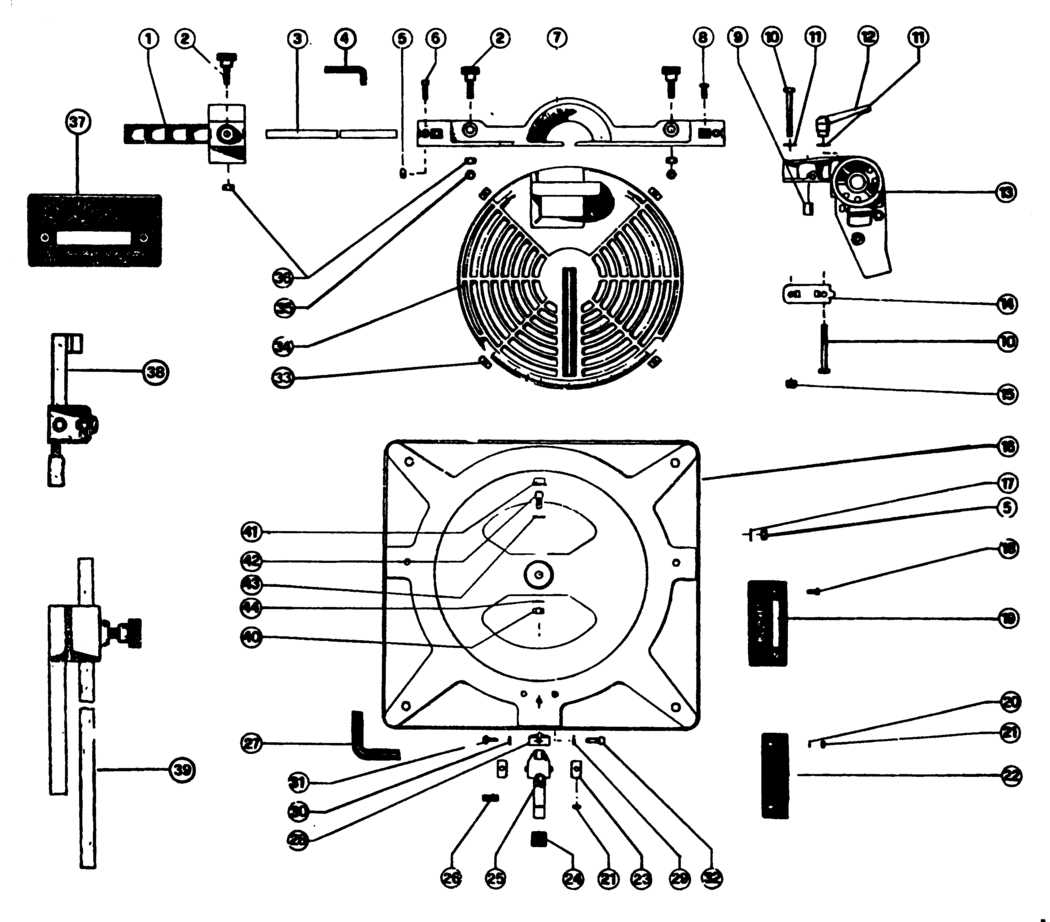

Interpreting the layout of a tool’s structure is essential for understanding its internal workings. These layouts provide a visual guide that highlights the different elements and their arrangement. By learning how to read these layouts, you can easily identify each part and its function within the tool.

Identifying Key Sections

In most layouts, the image is divided into several sections, each corresponding to a specific part of the tool. The sections might include:

- Motor and power system

- Cutting mechanisms

- Support structures and housing

Reading the Labels and Numbers

Each component in the layout is typically labeled with a reference number. These numbers correspond to specific parts listed in the tool’s manual or parts catalog. Pay attention to these numbers to ensure accurate identification when ordering replacements or during repairs.

- Locate the part number on the layout.

- Find the same number in the manual or catalog.

- Match the part’s description to its function.

Common Issues and Repairs for Components

Every tool is prone to wear and tear, and certain components are more susceptible to damage than others. Recognizing common issues early can save you time and money on repairs. This section will cover frequent problems with various elements and how to address them effectively.

Motor and Power Supply Problems

One of the most common issues in power tools is a malfunctioning motor or power supply. If the tool fails to start or runs intermittently, it could indicate issues with the motor’s electrical connections or the power cord. Inspect the motor for signs of overheating or damage, and check the power source for consistency. If the motor is damaged, it may need to be replaced.

Cutting Mechanism Failures

Cutting mechanisms can become dull, misaligned, or damaged over time. If the tool is not cutting efficiently or is producing uneven cuts, the blade may need sharpening or replacement. Check for any debris or buildup around the cutting area that could cause obstruction. Regular maintenance, including cleaning and lubricating moving parts, can help prevent premature failure.