Understanding the layout and functionality of your lawn tractor’s control system is essential for smooth operation and longevity. Whether you’re a DIY enthusiast or a seasoned technician, knowing the components involved can make maintenance and repairs much easier.

In this guide, we will walk through the key elements that make up the driving mechanism of your machine, offering insights into how each piece works together. A clear overview of these components helps to identify potential issues early and ensures your equipment runs efficiently.

From troubleshooting to replacing worn-out parts, proper knowledge of the system structure allows for more accurate repairs. This will save both time and money, ensuring your tractor performs at its best for years to come.

Understanding Tractor Control System

Having a solid understanding of the control mechanism in your lawn tractor is essential for effective operation and maintenance. This system consists of various components that work in harmony to ensure smooth navigation and precise maneuverability. When properly maintained, these elements allow the machine to perform reliably over time.

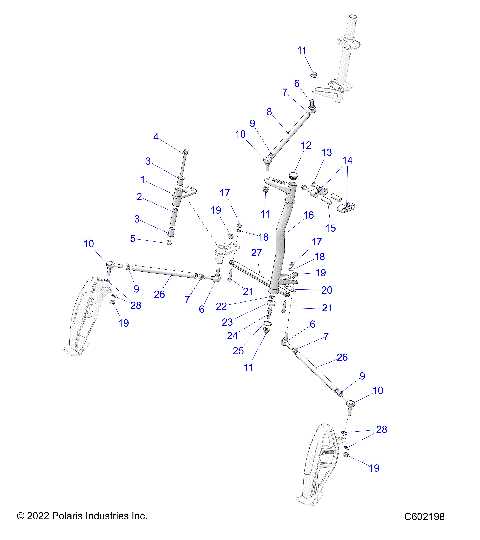

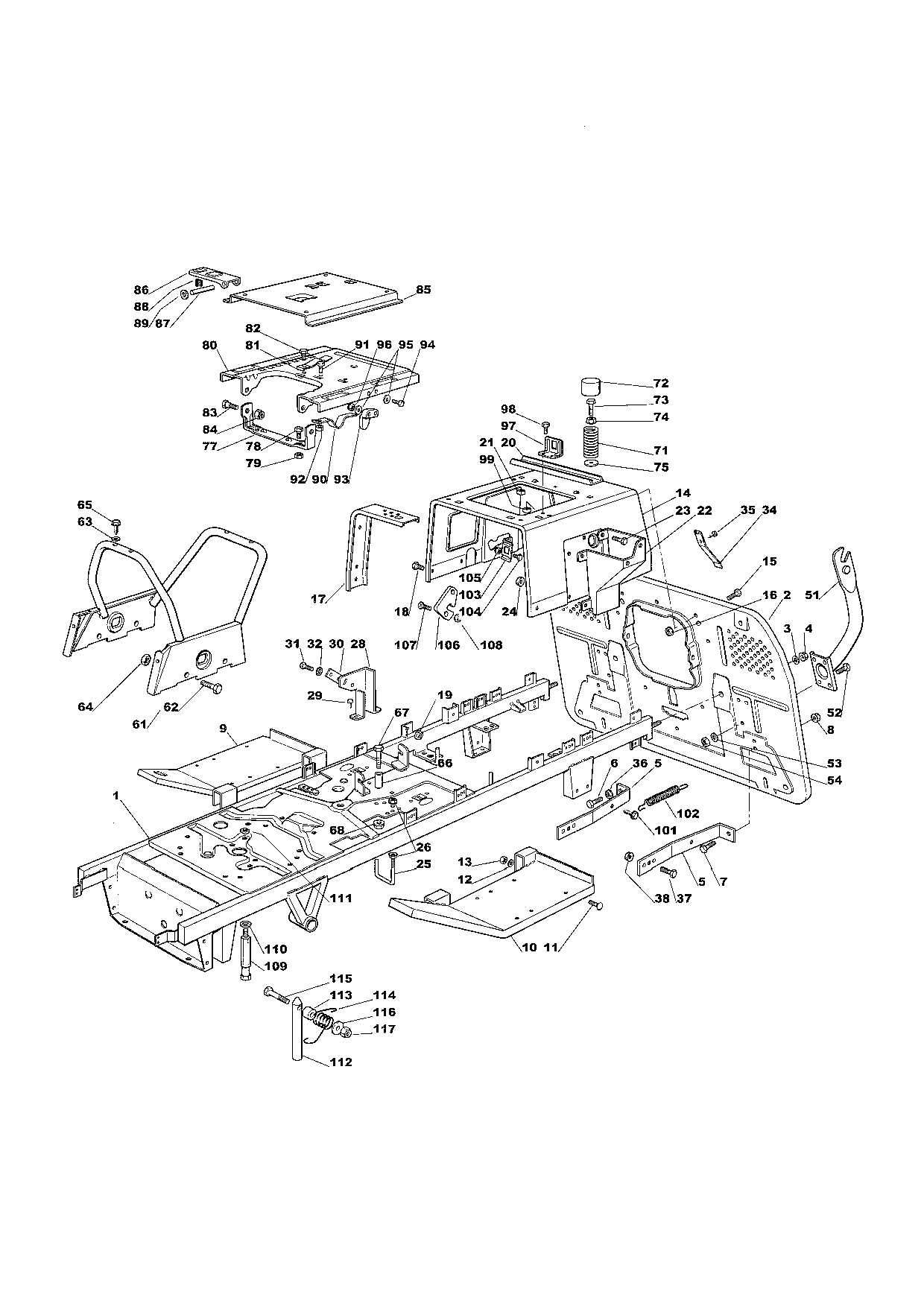

The control mechanism is responsible for converting the operator’s input into movement, allowing for direction changes and adjustments while driving. Key elements within this system include the various linkages, rods, and wheels that make up the assembly. Each of these components plays a vital role in ensuring proper function and durability.

Familiarizing yourself with how these elements interact can help in troubleshooting common issues, such as difficulty in turning or unresponsiveness. Knowing the layout of the system and how to maintain it will lead to longer-lasting performance and more efficient repairs when problems arise.

Key Components of the Control Mechanism

The driving system of a lawn tractor is made up of several crucial components that work together to ensure proper functionality. These elements are responsible for converting the operator’s input into the movement of the machine, enabling it to change directions and navigate through various terrains smoothly.

One of the primary components is the rack and pinion, which helps control the turning motion. The linkage system, including rods and levers, connects the control wheel to the wheels, allowing for precise adjustments. Additionally, the steering column and the associated bearings provide stability and smooth operation, ensuring that every movement is responsive and consistent.

Understanding the role of each of these key elements is important when troubleshooting issues or performing maintenance. Regular inspection and upkeep of these components can prevent mechanical failures and extend the lifespan of the equipment.

How to Repair Tractor Control Mechanism

When the control system of your lawn tractor starts to malfunction, it’s crucial to address the issue promptly to ensure smooth operation. Regular inspection can help identify signs of wear and prevent more significant problems down the line. If you notice difficulty turning or lack of responsiveness, it may be time for repairs or part replacements.

Inspecting and Diagnosing the Issue

The first step in repairing any mechanical system is to properly diagnose the problem. Check the linkage and the rod connections to ensure they are intact and properly aligned. Look for any signs of rust, bending, or wear, as these can cause the system to malfunction. If the system is unresponsive, it may be due to a worn-out component or loose connections.

Replacing Damaged Components

If you’ve identified damaged parts, it’s time to replace them. Start by removing the faulty components carefully, paying attention to how they are connected to the rest of the system. Replace the worn-out parts with high-quality replacements, and reassemble the system according to the manufacturer’s guidelines. Ensure that everything is tightly secured to prevent future issues.

Once the repair is complete, test the mechanism by turning the wheel and checking the movement of the wheels. If the response is smooth and consistent, the repair has been successful. Regular maintenance will help prevent future breakdowns and keep your equipment running efficiently for years.