Farm machinery relies on efficient connection mechanisms to perform a wide variety of tasks. The components that facilitate these attachments are essential for ensuring smooth operation and optimal performance. Understanding these elements is crucial for maintenance and troubleshooting.

Detailed knowledge of each component allows operators to properly assess and maintain the functionality of the equipment. Properly managing these connections prevents downtime and enhances the machine’s overall lifespan.

For those looking to improve their skills or handle repairs, a clear understanding of how the system works and the role of each element is vital. With the right approach, keeping machinery in top condition becomes a much simpler task.

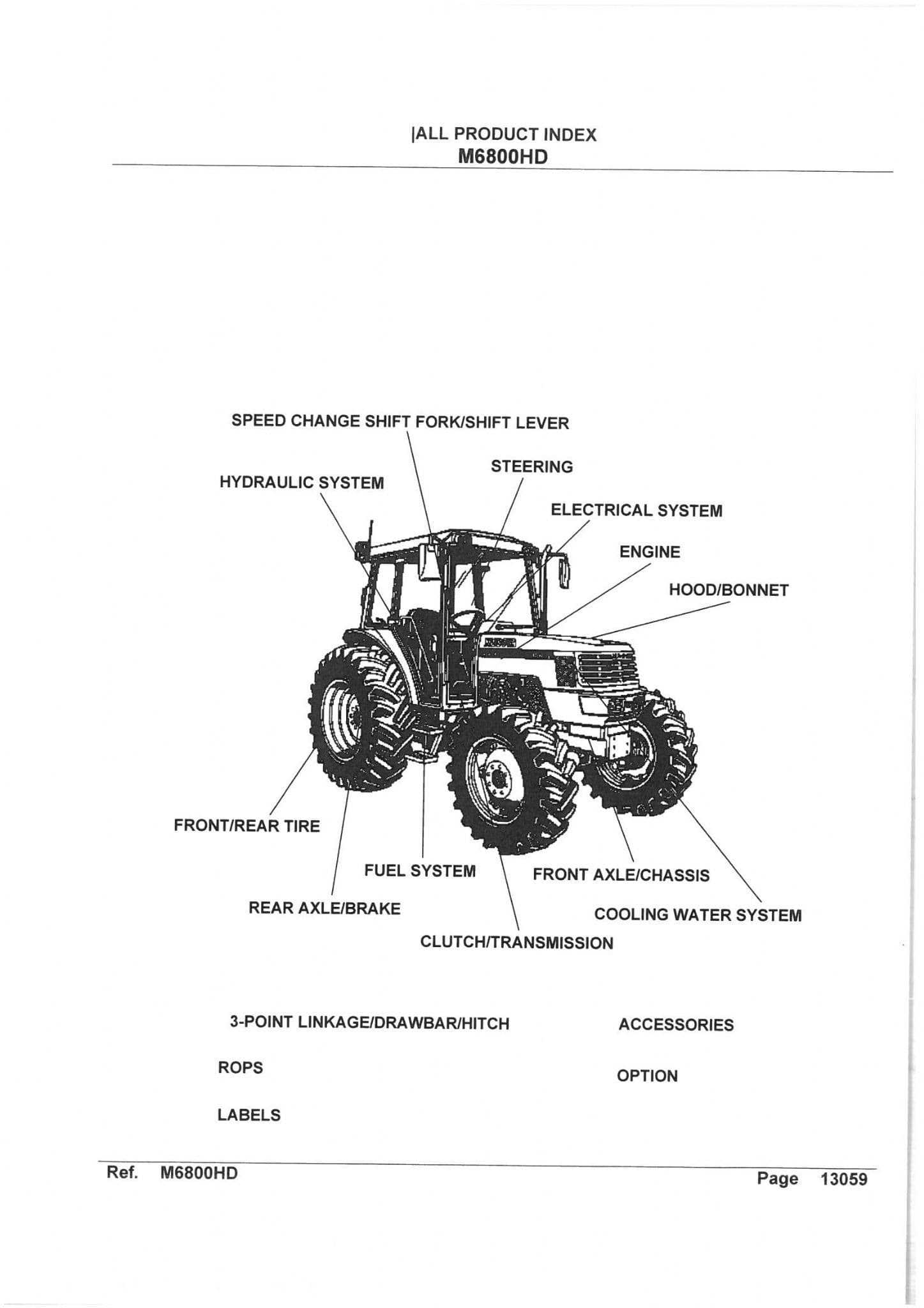

Understanding Tractor Attachment System

In agricultural machinery, efficient connection systems are vital for attaching various tools and implements. These systems are designed to provide secure and reliable engagement between the tractor and the equipment, allowing for smooth operation across different tasks. A thorough understanding of these systems ensures that operators can maintain and troubleshoot the equipment effectively.

Key Components of the Connection System

The core components of the system include mechanisms that allow for flexibility, strength, and stability. These elements ensure that the implements are securely attached and can be easily adjusted to suit various working conditions. Understanding the purpose of each part is crucial for making necessary adjustments and repairs.

Importance of Proper Functionality

Properly functioning attachment systems contribute to the overall performance and durability of agricultural machinery. When each component operates as it should, it minimizes wear and tear, reduces downtime, and enhances the efficiency of tasks. Regular maintenance and quick identification of issues are essential for long-term equipment reliability.

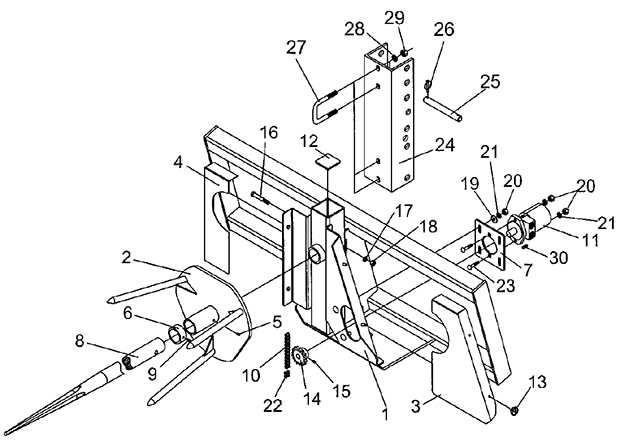

Components and Functions of the Attachment System

The connection system used in agricultural machinery is composed of several essential elements that work together to ensure smooth engagement between the tractor and the various implements. These components are designed to provide stability, flexibility, and control, allowing operators to handle a wide range of tasks with ease. Understanding how each part functions is key to optimizing the performance of the entire system.

Main Components

The key elements of the system include the frame, locking mechanisms, and adjustable arms. Each part plays a specific role in maintaining a secure attachment, while also allowing for adjustments based on the requirements of different tools and equipment. These components ensure that the tractor and implements work in tandem to maximize efficiency and safety.

Functionality and Adjustment

Each component serves a distinct function that contributes to the overall effectiveness of the system. The adjustable arms, for instance, allow for the positioning of the implement at the correct height and angle. The locking mechanisms provide security, preventing unwanted detachment during operation. Regular inspection and proper adjustments ensure that the system remains functional and efficient throughout its lifespan.

How to Maintain Tractor Attachment Components

Regular maintenance of the components that secure implements to agricultural machinery is essential for ensuring long-term functionality and minimizing downtime. Proper care of these elements can prevent costly repairs and improve the overall performance of the equipment. Routine checks and adjustments are vital for identifying potential issues before they become major problems.

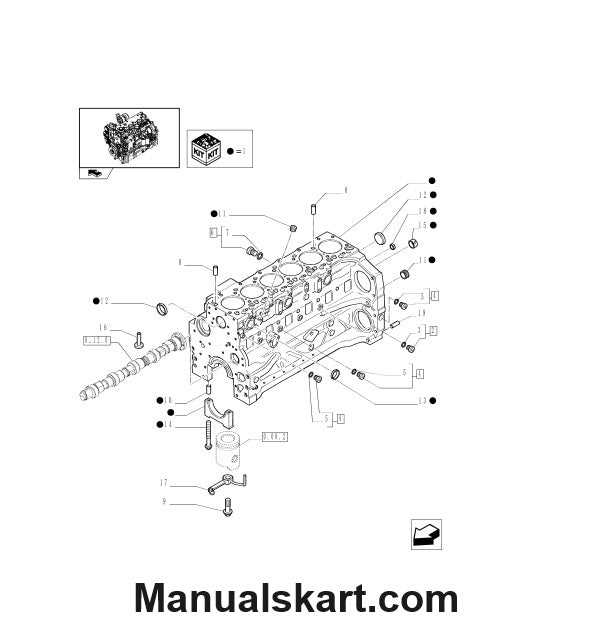

Inspection and Lubrication

Frequent inspection of the attachment system is crucial for detecting wear or damage to the components. Check for any loose parts, rust, or signs of excessive friction. Applying the appropriate lubricant to moving parts helps reduce wear and keeps the system operating smoothly. Be sure to use the recommended type of lubricant to avoid damage to sensitive components.

Adjustment and Tightening

Over time, the components may require adjustment to maintain optimal functionality. Ensure that all connections are secure and tightly fastened. Regularly adjust the height and angle of the system to ensure that it is aligned properly for each task. Tightening loose bolts and fasteners can prevent further damage and improve the safety and efficiency of the system.