Proper maintenance and repair of machinery rely on a clear understanding of its internal components. Familiarizing yourself with the structure and functionality of each part ensures that you can troubleshoot effectively and make precise replacements when necessary. Knowing how each element works together helps in maintaining the longevity and efficiency of the equipment.

Having a visual reference to guide you through the different sections of your machinery can be incredibly helpful. It allows you to identify specific components and their roles, making it easier to locate potential issues. This guide offers a simplified approach to understanding how the parts interact and how to address common concerns.

Whether you’re dealing with wear and tear or simply performing routine checks, understanding the configuration of the system will make your tasks easier. Accurate identification of components not only saves time but also prevents mistakes during repairs. Focusing on the layout and function of each part allows you to work with confidence and precision.

Understanding the Components of Your Equipment

When working with any mechanical device, it’s essential to understand the role of each element within the system. Each individual component is designed to perform a specific function, and together they create a cohesive unit that operates smoothly. A clear understanding of how these elements are organized and interact can significantly improve your ability to maintain and repair the device effectively.

Key Components and Their Functions

The device consists of several major sections, each responsible for a different aspect of operation. From the engine’s driving mechanism to the control system, each part must work seamlessly with others. The structure of the unit is designed for durability and efficiency, with parts crafted to withstand wear and tear over time.

Identifying Issues and Fixes

Recognizing the function of each part allows you to quickly identify issues when they arise. Common malfunctions can often be traced back to specific components. For example, a faulty connection or worn-out element may cause the entire system to malfunction. By understanding each part’s role, you can pinpoint the problem with greater accuracy and make the necessary repairs or replacements more efficiently.

Maintaining an understanding of the assembly and layout of each piece will make the repair process smoother and more effective. Focusing on the key areas and addressing them promptly ensures that your machine continues to operate at its best for an extended period.

How to Read the Assembly Layout

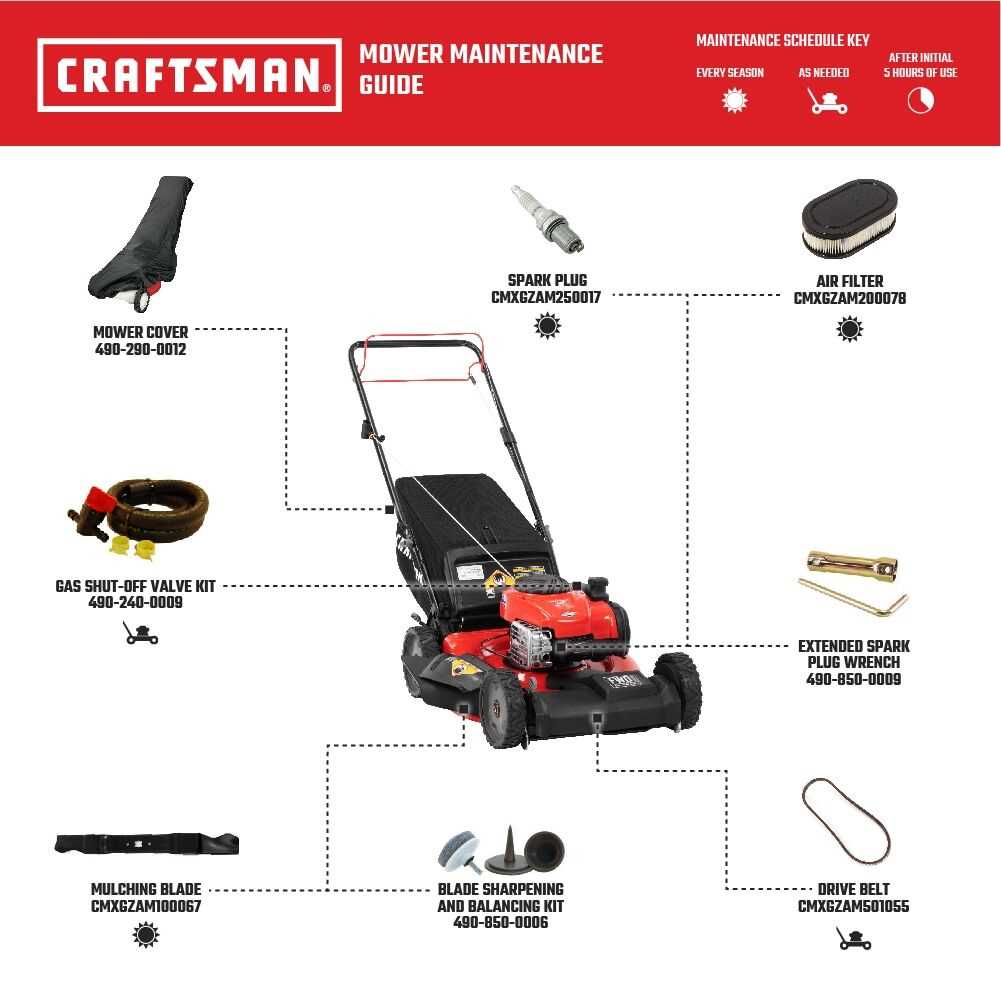

Understanding how to interpret a visual reference for mechanical components is essential for effective maintenance and repairs. These illustrations provide a clear overview of the machine’s structure, showing how various elements are positioned and connected. By learning to read these representations, you can quickly identify the parts that require attention.

Each component is typically labeled with a number or code, which corresponds to a specific item in the associated reference guide. This system allows you to match the visual representation with the actual part, making it easier to locate replacements or identify any issues. The layout often shows how parts fit together, helping you understand their relationships and how they contribute to the overall functionality.

To effectively use these guides, start by identifying the section of the layout that corresponds to the area you’re working on. From there, follow the lines and connections to locate each part’s placement. The more familiar you become with the format, the quicker you’ll be able to pinpoint specific components and address any issues that arise.

Common Issues and Replacement Tips

Every mechanical system experiences wear and tear over time, and certain components may need to be replaced to keep the device functioning properly. Recognizing common issues early on can save you time and money, ensuring that repairs are done quickly and efficiently. Understanding the most frequent problems allows you to focus on the areas that are most likely to need attention.

One common issue is the deterioration of moving parts due to friction and regular use. Over time, this can lead to decreased performance or complete failure. Replacing these parts with high-quality replacements can restore the system’s original efficiency. Another frequent problem is misalignment or loosening of components, which may cause rattling or malfunction. Regularly checking and tightening these elements can prevent further damage.

When replacing any part, it’s essential to choose components that match the specifications of the system. Incorrect parts can lead to improper functioning or even further damage. Always consult the user manual or a detailed guide to ensure you select the right replacement for each issue. By following proper replacement procedures and performing routine checks, you can extend the life of the system and avoid unnecessary repairs.