Maintaining equipment requires a clear understanding of its structure. A detailed overview of essential components can make repairs and upkeep simpler. By recognizing each element’s role, users can ensure optimal performance and longevity of their machines.

With a comprehensive visual guide, identifying each crucial part becomes easier. Knowing how these elements fit together helps in troubleshooting issues and performing necessary maintenance tasks. This knowledge can prevent common problems, reducing downtime and enhancing efficiency.

Briggs and Stratton Cleaner Components Overview

Understanding the different elements of a pressure washing tool is essential for maintaining its performance. Each component plays a specific role in the overall function, from the rotating mechanism to the housing and connecting parts. Recognizing how these parts work together can simplify repair and maintenance tasks.

Among the key features, the rotating unit is responsible for creating the cleaning effect, while other sections manage water flow and pressure distribution. The protective covers ensure the safety and longevity of the internal components, preventing damage from external factors. Knowing their arrangement and function is crucial for troubleshooting and optimal usage.

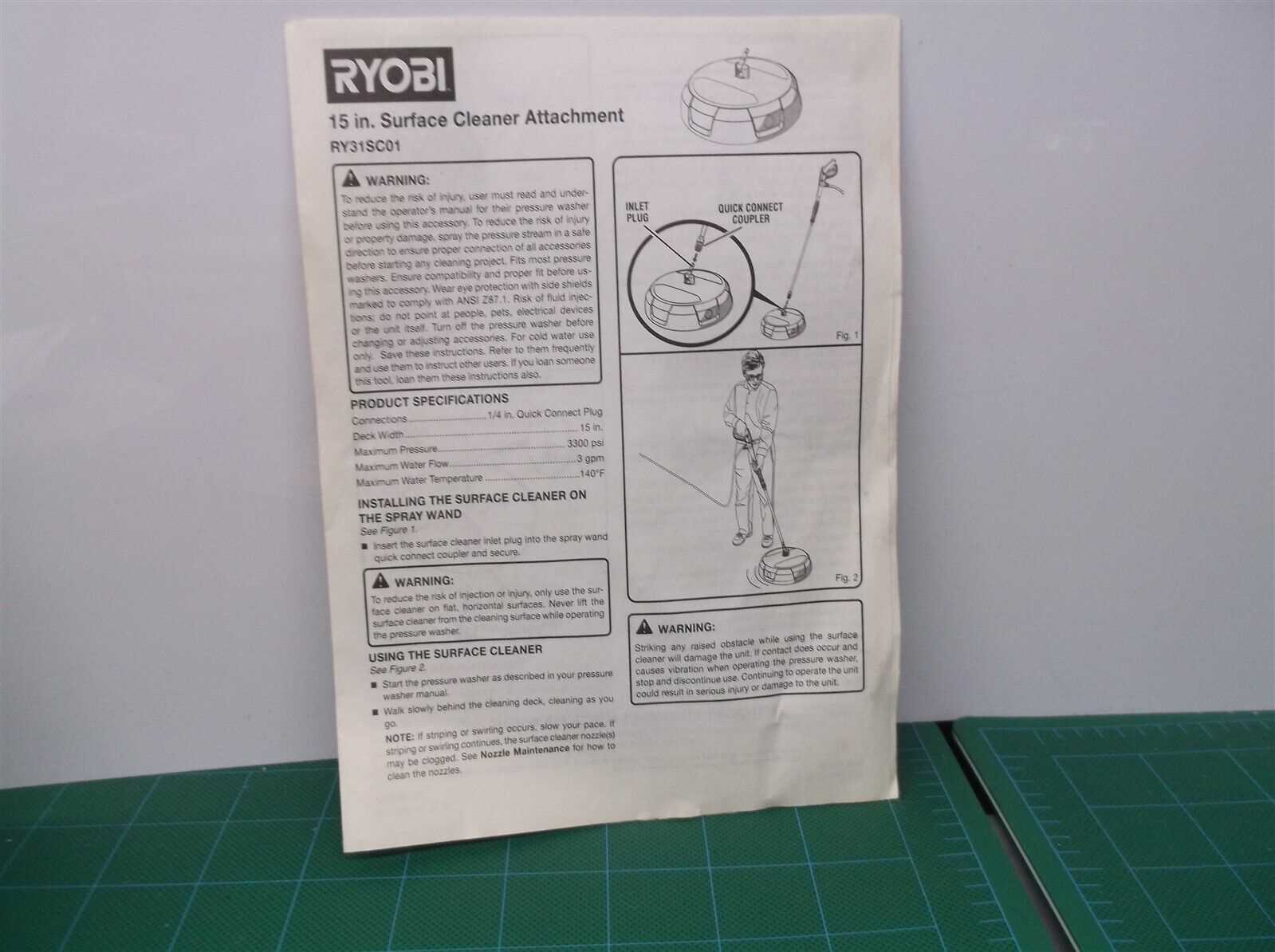

Understanding the Surface Cleaner Diagram

A detailed visual representation of equipment components helps users understand how different sections interact and function together. Such diagrams provide clarity on how each element fits into the overall system, making it easier to identify issues or areas in need of maintenance. By analyzing the layout, it becomes possible to pinpoint specific parts and their roles in operation.

Each part’s position in the layout reveals its connection to the entire structure. Understanding this can assist in effective troubleshooting and repair, as it highlights the flow and movement within the system. Familiarity with the illustration makes it easier to address malfunctions by focusing on the most relevant components based on their placement and function.

How to Identify Parts in the Diagram

Recognizing individual components in a technical illustration is a key step in understanding how the equipment operates. By carefully examining each section, users can link the visual representation to the actual machine, allowing them to locate and distinguish between different elements. This knowledge is essential for efficient repairs and maintenance tasks.

Step-by-Step Identification Process

The first step in identifying components is to familiarize yourself with the overall layout. Pay attention to the labels and markings next to each item in the diagram. These indicators will often show the part number or name, which you can cross-reference with the user manual for exact details. Additionally, noting the shape and placement of each piece helps you distinguish between similar-looking parts.

Common Identifiers to Look For

Parts in diagrams are typically highlighted with distinct lines or shading to make them stand out. Focus on the most prominent elements first, such as the rotating mechanisms, handles, or connectors. These features are often the most critical for proper functionality, and identifying them will help guide you toward more complex parts when needed.