When maintaining or repairing your outdoor equipment, it is essential to have a clear understanding of its various components and their functions. Knowing how each part contributes to the overall operation can help you troubleshoot issues and ensure efficient performance. By familiarizing yourself with the internal mechanisms, you can easily identify problems and make necessary adjustments or replacements.

Proper knowledge of your tool can prevent unnecessary breakdowns and extend its lifespan. From the engine to the cutting mechanism, every piece plays a role in delivering optimal results. With a comprehensive guide, you will be able to recognize the key elements and how to manage them effectively, allowing for smooth operation in the long run.

In this guide, we’ll walk you through the essential steps to understand the assembly, identify important components, and learn how to care for your machine to keep it running smoothly season after season.

Understanding Equipment Components

For any outdoor tool, understanding its individual components is essential for proper maintenance and troubleshooting. Each element of the machine is designed to perform a specific function, contributing to its overall performance. Knowing how these pieces work together can help you identify potential issues and take the appropriate steps to ensure the tool continues to operate effectively.

Key Functional Elements

The most crucial parts of any tool include the engine, fuel system, and cutting mechanism. The engine provides the necessary power for operation, while the fuel system ensures a steady supply of energy. The cutting mechanism, responsible for the work at hand, needs to be properly maintained to ensure efficient performance and longevity. A solid understanding of these core components can make repairs easier and more straightforward.

Maintaining and Replacing Components

Regular maintenance is key to prolonging the life of your tool. Identifying worn-out or damaged parts and replacing them on time will help keep everything running smoothly. Ensuring proper lubrication, checking for fuel blockages, and monitoring the condition of the cutting components can prevent many common problems. By staying on top of these tasks, you will avoid unnecessary downtime and enjoy the full potential of your machine.

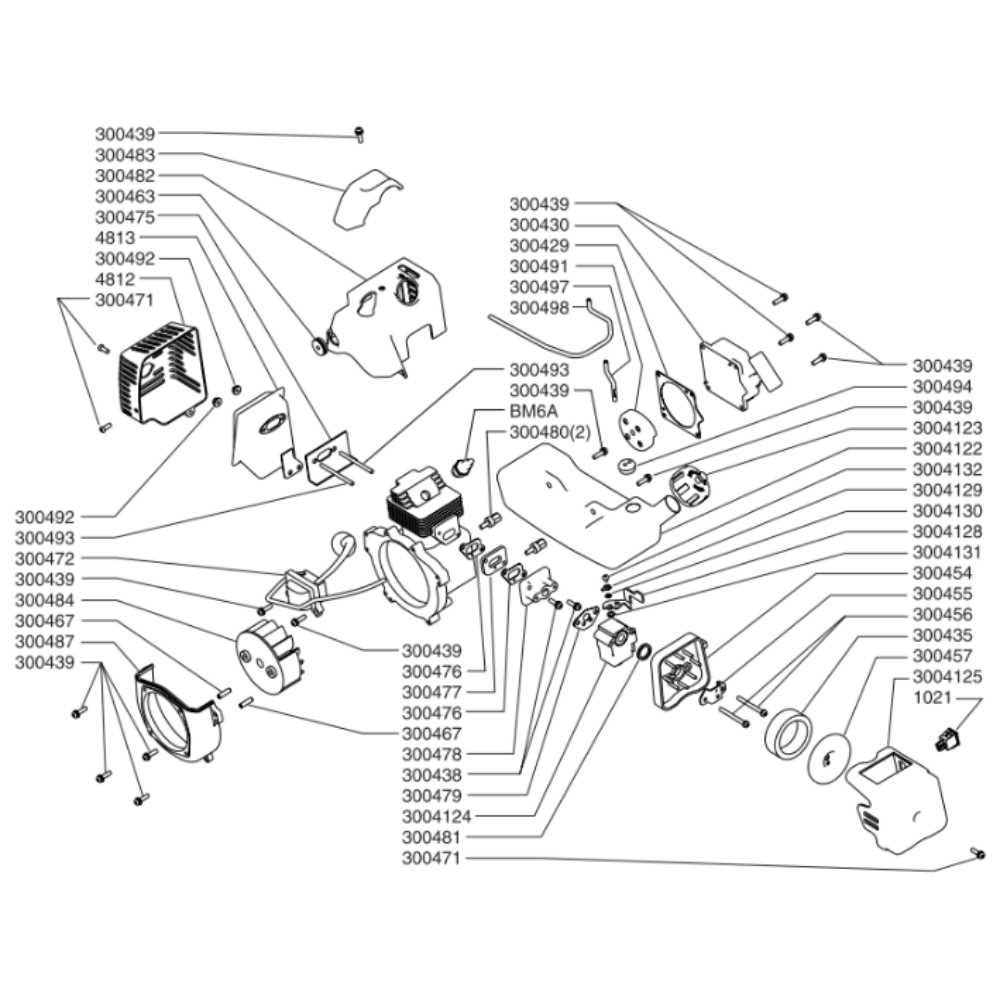

How to Identify Key 30cc Components

Recognizing and understanding the key components of your outdoor tool is essential for proper maintenance and repair. Knowing where each part is located and its function within the machine allows for more efficient troubleshooting and replacement. By focusing on the most vital elements, you can ensure smooth operation and avoid costly mistakes when handling your equipment.

Recognizing Core Mechanisms

The engine, fuel system, and cutting mechanism are the primary components to familiarize yourself with. The engine powers the tool, while the fuel system delivers energy for operation. The cutting system is what performs the actual task, whether it’s trimming or cutting, and needs to be in top condition for peak performance. Identifying these core systems will help you focus your attention on the areas most likely to need maintenance.

Identifying Wear and Tear

Over time, certain components will show signs of wear that could hinder the tool’s performance. The fuel lines may become cracked, the engine parts could wear out, or the cutting system might need sharpening or replacing. Regular inspection of these components will help you spot potential issues early and address them before they cause significant problems. Maintaining these parts ensures the longevity and efficiency of your equipment.

Maintenance Tips for 4 Cycle Engines

Regular maintenance is crucial for ensuring the longevity and efficiency of your engine. By following a few simple practices, you can prevent common issues, reduce wear, and improve overall performance. Proper care helps keep your machine running smoothly and minimizes the need for costly repairs.

Essential Maintenance Tasks

- Change the oil regularly: Fresh oil is key to engine performance. Replace it according to the manufacturer’s recommendations to ensure smooth operation.

- Check and clean the air filter: A clogged filter can restrict airflow and affect engine performance. Clean or replace it as needed to maintain optimal efficiency.

- Inspect fuel lines: Over time, fuel lines can deteriorate. Check them periodically for cracks or leaks and replace them to avoid engine malfunctions.

- Examine spark plug: A dirty or faulty spark plug can cause starting issues. Clean or replace it to maintain reliable ignition.

Preventive Measures

- Store properly: When not in use for extended periods, drain the fuel tank to prevent clogging and corrosion in the fuel system.

- Keep the engine clean: Dirt and debris can build up, causing the engine to overheat. Regularly clean the exterior to prevent this from happening.

- Use quality fuel: Low-quality or stale fuel can damage engine components. Always use fresh, high-quality fuel to prolong engine life.

Ensure Smooth Operation of Your Tool

To get the best performance from your outdoor tool, consistent maintenance and proper usage are essential. A well-maintained machine not only works more efficiently but also has a longer lifespan. Regular checks and simple care routines can make a significant difference in ensuring your equipment operates smoothly throughout its life.

Regular Maintenance Practices

- Keep the machine clean: Regularly remove dirt, grass, and debris from the exterior. This prevents clogging and allows the engine to breathe properly.

- Check the fuel system: Ensure the fuel lines are intact and the tank is filled with fresh fuel. Stale or contaminated fuel can lead to starting issues and poor performance.

- Inspect the cutting mechanism: Regularly examine the blades or cutting head for wear and tear. Sharpen or replace as necessary to maintain cutting efficiency.

Proper Usage Tips

- Avoid overloading: Do not force the tool to handle more than it can. Let it operate at its optimal pace for longer-lasting results.

- Use the right fuel: Always use the recommended fuel type to avoid damaging the engine or fuel system.

- Store correctly: When not in use, store the tool in a dry place and remove any remaining fuel to prevent corrosion and clogging in the fuel system.

Replacing Components in Your Outdoor Tool

Over time, certain components of your equipment may need replacement due to wear or damage. Replacing these parts promptly ensures the machine continues to function properly and avoids further complications. Understanding how and when to replace specific components can save time and money while maintaining optimal performance.

Identifying When Replacement is Necessary

- Signs of damage: Look for visible signs such as cracks, fraying, or excessive wear on any components.

- Performance issues: If your tool struggles to start or operate smoothly, it may indicate that a part is no longer functioning properly and needs replacement.

- Frequent malfunctions: If you notice the same issue occurring repeatedly, it could be a sign that a key part is deteriorating and requires attention.

Step-by-Step Replacement Process

- Turn off and disconnect: Always turn off the machine and disconnect any power sources before working on it to ensure safety.

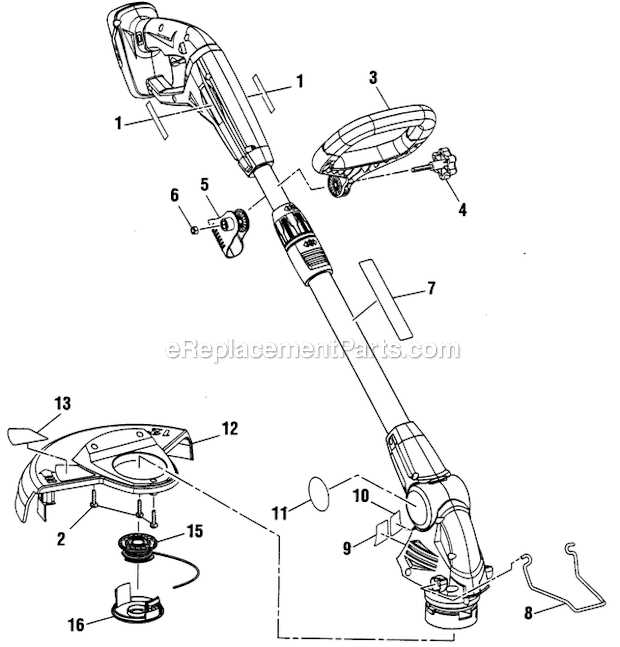

- Locate the damaged part: Refer to the user manual or maintenance guide to identify the specific component that needs replacing.

- Remove and replace: Carefully remove the damaged part and replace it with the new one, ensuring it is securely attached and properly aligned.