When working with any complex machinery, understanding its internal structure is essential for efficient maintenance and repair. The ability to identify each element and how it fits into the larger system ensures smooth operation and helps prevent potential issues. Having a clear visual representation of the individual components can save time and resources during troubleshooting or when seeking replacements.

For enthusiasts and mechanics alike, it is crucial to become familiar with the way every part interacts. A comprehensive map of the system not only aids in identifying malfunctioning components but also allows for more precise diagnostics. Knowing where to find specific elements makes the task of repairing or upgrading the vehicle much easier.

With proper guidance, anyone can navigate the mechanical layout of the vehicle and make informed decisions when it comes to repairs or replacements. This resource is designed to provide the clarity needed for optimal maintenance practices, ensuring that your machine runs efficiently for years to come.

Understanding Vehicle Components

To maintain a machine effectively, it is crucial to have a comprehensive understanding of its internal elements. Each part plays a specific role in ensuring optimal performance, and recognizing how they interact can prevent many common issues. Familiarity with the entire system allows users to diagnose problems more efficiently and ensure longevity with proper care and replacements.

Key Mechanical Elements

The core mechanical systems within any vehicle consist of interconnected parts, such as the engine, transmission, suspension, and electrical components. Understanding the function of each component helps identify potential issues early, making repairs less time-consuming and more effective. Knowing where each piece fits into the whole system can provide valuable insights for maintenance and troubleshooting.

Importance of Regular Inspections

Routine inspections are essential for identifying wear and tear on the internal systems. Checking critical components such as the powertrain, steering, and brake mechanisms ensures that small problems don’t develop into costly repairs. Regular maintenance guided by a clear understanding of the vehicle’s structure will keep it in peak condition and avoid unnecessary downtime.

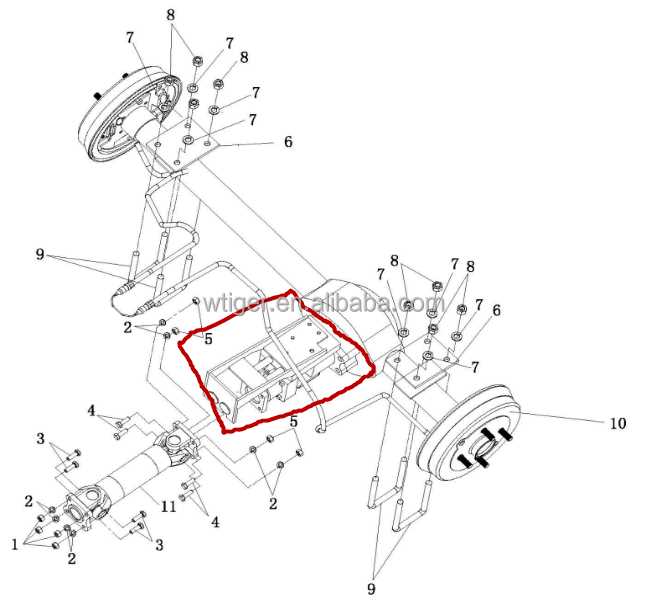

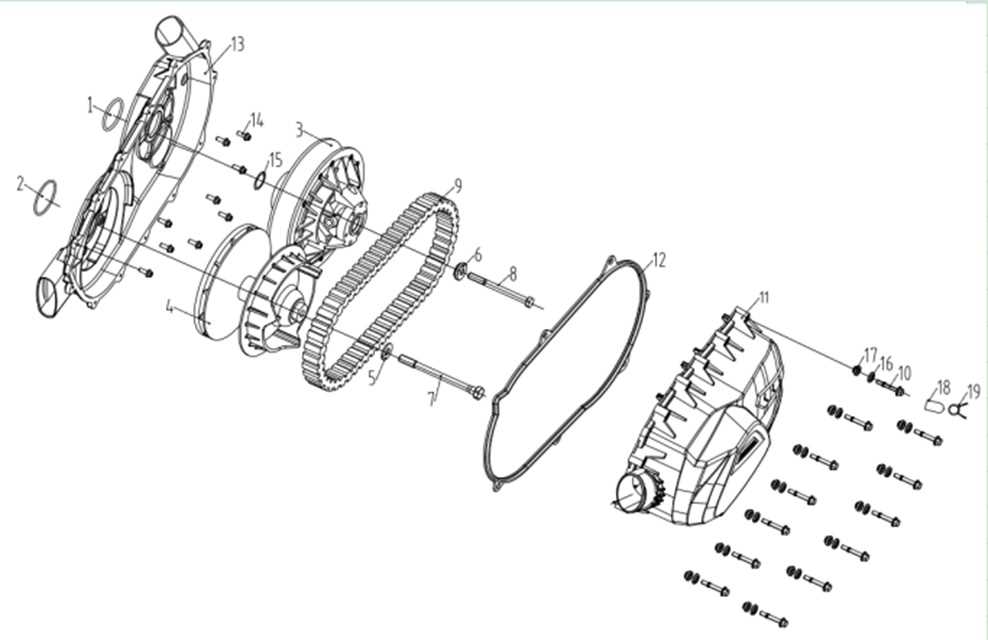

How to Use the Visual Breakdown Effectively

A clear visual representation of a machine’s internal structure is an invaluable tool for identifying components and their placement within the system. This guide will help you utilize this resource to streamline repairs, order replacements, and troubleshoot effectively. By understanding how each element fits into the larger framework, you can perform maintenance tasks with precision.

Steps to Maximize the Use of the Breakdown

- Study the Layout: Familiarize yourself with the overall structure and the positioning of each component to understand how they work together.

- Locate Specific Parts: Use the visual map to find the exact location of any malfunctioning or worn-out parts that need attention.

- Check Compatibility: Ensure that the parts you are replacing or upgrading are compatible with the rest of the system.

Common Mistakes to Avoid

- Overlooking Small Components: Don’t ignore smaller elements that might seem insignificant but can have a major impact on overall functionality.

- Misidentifying Parts: Always double-check the part numbers or references to avoid errors when ordering replacements.

By following these tips, you’ll be able to make informed decisions quickly and efficiently, reducing downtime and enhancing the performance of your machine.

Common Issues and Repair Tips

When dealing with any vehicle, certain issues tend to arise more frequently, often due to wear and tear on essential components. Identifying these problems early can save both time and money in repairs. This section outlines some of the most common malfunctions and provides tips on how to address them efficiently.

Engine Overheating

Problem: Overheating is a frequent issue caused by cooling system failure, low coolant levels, or blocked air vents. If left unchecked, it can lead to severe engine damage.

Repair Tip: Always check the coolant levels and inspect the radiator and hoses for leaks or clogs. Cleaning or replacing a malfunctioning thermostat can often resolve overheating problems. Make sure to inspect the cooling fan for proper function as well.

Brake System Failures

Problem: Diminished braking performance is a critical safety concern, often caused by worn brake pads, damaged rotors, or air in the brake lines.

Repair Tip: Regularly inspect the brake pads and replace them before they become too thin. Also, ensure that the brake fluid is at the correct level and bleed the lines if air bubbles are present.

Electrical System Malfunctions

Problem: Electrical issues, such as faulty wiring or a dead battery, are common and can lead to failure of lights, starting problems, or even complete power loss.

Repair Tip: Inspect the battery for corrosion and clean the terminals. Check the alternator to ensure it’s charging the battery properly. If electrical connections appear loose, tightening them can often resolve the issue.

Maintaining Your Vehicle

Proper maintenance is essential for ensuring the longevity and performance of any machine. Regular care and attention to the mechanical and electrical systems will prevent most common issues, reduce the need for expensive repairs, and keep the vehicle running smoothly. By following a structured maintenance routine, you can significantly enhance its reliability and overall lifespan.

Routine Checks

Engine Care: Regularly check the oil level and quality. Change the oil at the recommended intervals to prevent buildup of harmful residues that can cause engine wear. Also, inspect air filters and replace them when they appear dirty or clogged.

Cooling System: Ensure that the coolant is topped up and in good condition. Over time, coolant can degrade or leak, leading to overheating. Keep an eye on the radiator and hoses for any signs of wear or leaks.

Suspension and Tires

Suspension System: Inspect shock absorbers and springs for any signs of damage or leakage. A well-maintained suspension system improves the vehicle’s handling and comfort while reducing wear on other components.

Tire Maintenance: Regularly check tire pressure and tread depth to ensure optimal traction and safety. Rotate tires periodically to ensure even wear and extend their lifespan.

Where to Find Replacement Components

Finding the right replacements for damaged or worn-out parts is a crucial part of maintaining your vehicle. It’s essential to source high-quality components that are compatible with your machine to ensure smooth operation and avoid further issues. Whether you’re seeking an upgrade or just trying to replace a malfunctioning element, several options are available for acquiring the necessary items.

Authorized Dealers

Official Retailers: One of the most reliable sources for replacement components is through official dealerships or authorized service centers. These suppliers offer parts that are specifically designed for your vehicle model, ensuring compatibility and high quality. Additionally, purchasing through authorized channels often provides access to warranties and expert advice.

Online Marketplaces and Stores

Online Options: There are numerous online retailers where you can find a wide range of replacement parts, often at competitive prices. Websites specializing in vehicle components typically offer a large selection of items with detailed specifications to help you identify the right fit. Be sure to check reviews and ratings to ensure the reliability of the seller.

Specialized Forums and Groups: Online communities focused on vehicle maintenance and repair can also be a useful resource. Members often share recommendations for where to find affordable and high-quality components, as well as provide insights on parts compatibility.