When it comes to maintaining and repairing your lawn care equipment, having a clear overview of the machine’s structure is essential. Knowing how all the pieces fit together ensures that you can troubleshoot effectively and carry out repairs with ease. This guide provides a comprehensive look at the various elements that make up a typical lawn tractor, helping you identify the key components and understand their roles.

Detailed visuals and well-organized information can simplify complex tasks, allowing for a smoother maintenance experience. With the right resources, you can quickly pinpoint any issues and take action to fix them. From the engine to the wheels, every part plays a critical role in the machine’s overall performance. Understanding each component’s function is crucial for anyone looking to keep their equipment in top shape.

Proper knowledge of how everything works together can save time, effort, and money. Whether you’re replacing worn-out parts or performing routine checks, having a detailed reference is invaluable. By the end of this article, you’ll have the tools to confidently maintain your lawn tractor and ensure its longevity.

Understanding Lawn Tractor Components

Every lawn maintenance machine consists of various essential elements that work together to ensure optimal performance. Understanding how these components interact allows you to troubleshoot, maintain, and repair the equipment effectively. Each part of the machine plays a specific role, whether it’s in propulsion, power, or steering, and recognizing these functions will help you keep the machine in good working order.

Key Functional Elements

The engine, transmission, and cutting mechanism are the core functional units of the machine. The engine powers the entire system, while the transmission converts this power into movement. The cutting mechanism is responsible for maintaining the lawn by providing precision and efficiency. Understanding how these components interact ensures smooth operation and helps you identify any malfunctions early.

Support Systems and Accessories

In addition to the main functional components, there are also several support systems that enhance the machine’s usability. These include the suspension system, wheels, and steering, which contribute to a comfortable and controlled ride. Accessories such as the seat, dashboard, and storage compartments improve user experience. Familiarizing yourself with these systems can aid in overall maintenance and improve machine handling.

Essential Components for Maintenance and Repair

Regular maintenance and timely repairs are crucial to ensuring the longevity and smooth functioning of your lawn equipment. To perform these tasks efficiently, it’s important to be familiar with the key elements that require attention. These components are vital for the overall performance and dependability of the machine. Recognizing which parts need periodic servicing helps prevent unnecessary breakdowns and enhances the user experience.

Engine and Fuel System

The engine is the heart of the machine, providing the power needed for operation. Regular checks on the fuel system, including the fuel filter and lines, are necessary to maintain optimal engine performance. Ensuring the engine runs smoothly involves monitoring oil levels, spark plugs, and air filters. Keeping these components in good condition can significantly extend the life of the machine.

Transmission and Wheels

The transmission system is responsible for transferring power to the wheels, making it essential for smooth movement and operation. It’s important to inspect the belts, pulleys, and gear systems periodically to prevent wear and tear. Additionally, ensuring that the wheels are in good condition and properly aligned contributes to better traction and overall stability when using the equipment on various surfaces.

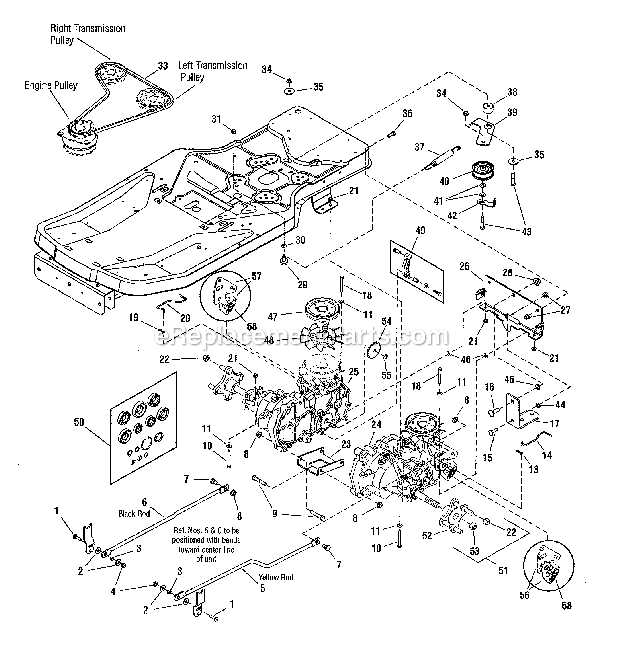

How to Use the Parts Diagram Effectively

Understanding how to read and utilize visual references for your machine’s components can greatly enhance the maintenance process. These visual guides help you locate and identify individual parts, making it easier to troubleshoot and replace faulty elements. By knowing how to navigate these resources, you can save time, reduce mistakes, and ensure that repairs are carried out correctly.

Locating Key Components

The first step in using a visual reference effectively is identifying the most critical components of the machine. Pay attention to areas such as the engine, transmission, and cutting system, as these require regular maintenance. Using the guide to locate each part quickly allows you to focus your efforts on specific issues without wasting time searching for the right components.

Following the Reference for Assembly

When performing repairs or assembling parts, following the visual reference ensures accuracy. The diagram provides a step-by-step approach to how each element connects, making reassembly easier. By carefully following the guide, you can avoid incorrect assembly and ensure that all parts are positioned and secured properly for optimal functionality.