Maintaining and repairing your outdoor equipment requires a solid understanding of its structure and individual elements. A visual reference that clearly marks each component is invaluable when performing any maintenance tasks. This guide will help you identify the various sections of your machine and assist in troubleshooting or replacing worn-out components.

In order to efficiently service your lawn equipment, it’s essential to be familiar with its layout and individual components. With the right tools and knowledge, identifying each part becomes easier, ensuring smoother repairs and fewer mistakes. A detailed map of all the key sections can save both time and effort, preventing unnecessary disassembly and helping you focus on the issue at hand.

Whether you’re an experienced technician or a homeowner looking to handle basic repairs, understanding your equipment’s setup is crucial. With a well-labeled reference, you can confidently approach any maintenance or upgrade, ensuring that everything is in optimal working condition. Knowing what part does what will make every project more straightforward and efficient.

Understanding Lawn Equipment Components

When working with lawn care machinery, understanding the essential components is crucial for effective maintenance and repair. Each piece plays a vital role in the overall performance, and being able to identify them will save time during troubleshooting. This knowledge helps ensure that you can address any issues quickly and confidently, whether you’re performing routine maintenance or fixing a malfunction.

The system of interconnected parts must function in harmony for optimal results. Each segment, from the cutting mechanism to the drive components, needs to be properly maintained to prevent premature wear and avoid costly repairs. A clear understanding of how these elements work together allows you to assess the condition of the equipment and determine what needs attention.

Proper care involves not only knowing how each piece operates but also recognizing when it’s time for a replacement or adjustment. Regular inspection helps you catch small problems before they turn into bigger ones, ensuring that your equipment remains in top working condition throughout its lifespan. Recognizing the importance of each element will ultimately lead to improved efficiency and a longer-lasting machine.

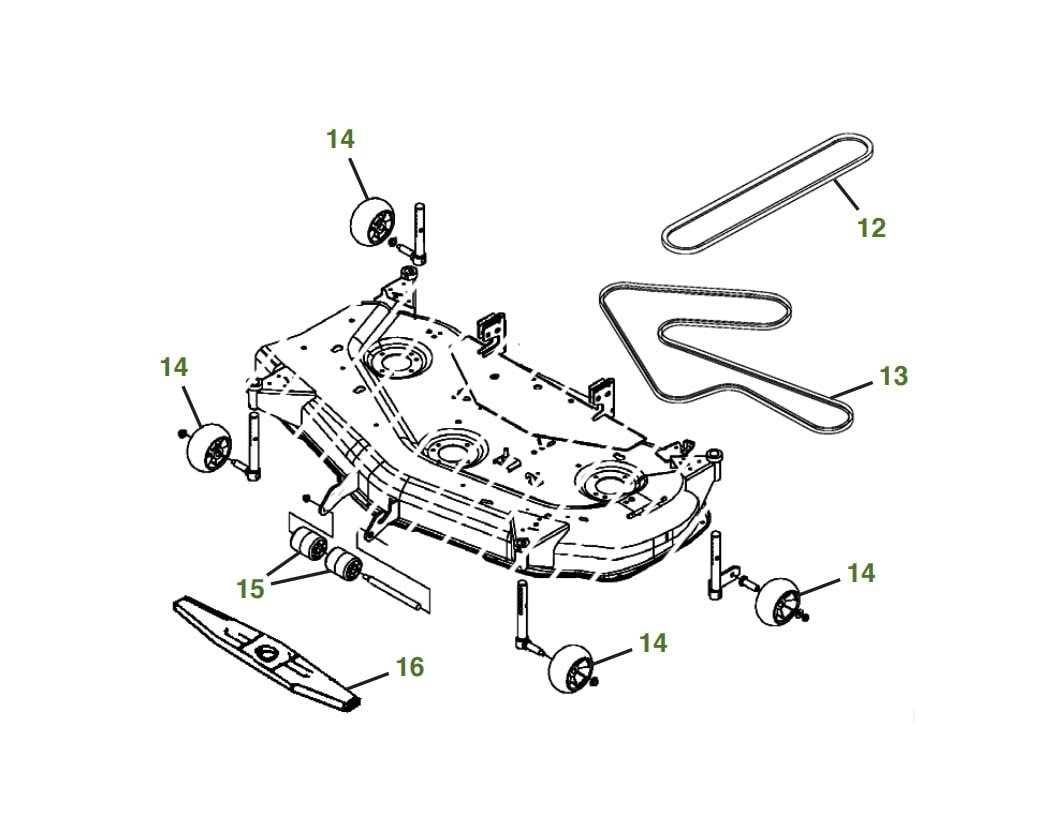

Essential Parts of the 54 Inch Cutting System

To ensure smooth and effective operation, the cutting system of any outdoor equipment relies on a series of key components working together. Each part has a specific function, contributing to the overall performance and efficiency. Understanding these essential elements can help you keep your machinery in optimal condition, reducing wear and tear and preventing unnecessary downtime.

One of the most important sections is the cutting blade assembly, which is responsible for achieving an even cut. Additionally, the belt-driven mechanism plays a significant role in transferring power to the blades. Other vital components, such as pulleys and spindles, ensure that the system operates smoothly, providing consistent results throughout its use.

Another crucial element is the support framework, which holds everything in place and allows for smooth operation across different terrains. Regular inspection of these parts is necessary to detect any signs of damage or wear. Proper maintenance of each section will extend the lifespan of your equipment and maintain its cutting efficiency over time.

How to Use the Parts Diagram Effectively

When performing maintenance or repairs, having a clear reference guide for identifying each component is essential. A well-organized visual map can simplify the process, making it easier to find and replace damaged parts. By understanding how to read and navigate this guide, you can ensure that you don’t miss any crucial elements during the service process.

Step-by-Step Identification

Start by carefully examining the reference guide to familiarize yourself with the layout. Each section should be labeled with a number or letter, corresponding to the components in your machine. Take note of the key areas where components are connected, as these are often where issues can arise. Using the map to identify each piece ensures that you don’t waste time searching for parts or disassembling unnecessary areas.

Maximizing Efficiency with the Diagram

Using a reference map can save significant time during repairs. By first identifying the problem area and then locating the relevant parts, you can focus your efforts on the most affected sections. Additionally, having a clear understanding of how each component fits together helps avoid mistakes when reassembling, reducing the risk of further damage.