When it comes to maintaining and repairing a high-performance small motor, having a clear understanding of its internal structure is essential. This section will guide you through the key elements that make up a 24 HP unit, offering valuable insights for both beginners and experienced users alike.

By breaking down the essential components, you will learn how each piece contributes to the overall function and efficiency of the system. This knowledge not only helps in identifying parts during maintenance but also aids in troubleshooting and enhancing performance.

Familiarity with these critical components will allow you to address any issues promptly, ensuring that the motor operates smoothly and reliably over time. Whether you’re replacing worn-out elements or simply seeking to understand their roles, a detailed overview of these structures will provide the foundation for effective care.

Understanding the 24 HP Small Motor

To fully appreciate the functionality and performance of a 24 HP motor, it’s essential to understand the various systems working in tandem within its structure. Each unit consists of a carefully arranged set of components that enable it to generate power efficiently and reliably. From fuel intake to exhaust, every part plays a crucial role in maintaining optimal performance.

Key Functional Units

At the heart of the system is the power generation mechanism, which relies on several interconnected elements. The combustion process, controlled by the ignition system, works alongside the intake and exhaust systems to provide a continuous flow of power. Additionally, components like the lubrication system and cooling mechanisms ensure the motor operates without overheating or excessive wear.

Efficiency and Durability

Understanding how these elements interact is vital for maximizing both the efficiency and longevity of the unit. Proper maintenance of each part ensures that the motor runs smoothly, reducing the likelihood of breakdowns and enhancing its overall lifespan. With a clear understanding of these functions, you’ll be better equipped to manage maintenance and repairs effectively.

Key Components of Small Motors Explained

Understanding the crucial elements within a motor is vital for proper maintenance and repair. Each component works together to ensure the smooth operation of the system, contributing to its power output, efficiency, and longevity. This section breaks down the essential components that make up a 24 HP small motor, providing insight into their functions and interconnections.

The combustion chamber is at the core of the power generation process. It is where the air-fuel mixture is ignited, producing the energy that drives the motor. Close behind in importance are the valve system and crankshaft, which manage the intake and exhaust processes and convert linear motion into rotational force.

Another key component is the lubrication system, which ensures that all moving parts are adequately oiled to prevent friction and excessive wear. Additionally, the cooling system plays an essential role in regulating temperature to avoid overheating, ensuring that the motor continues to run at optimal levels.

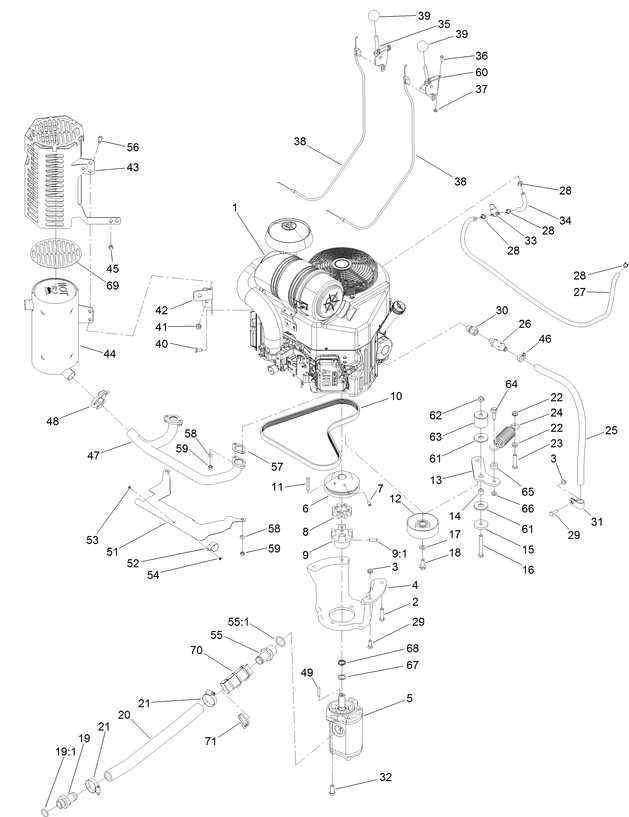

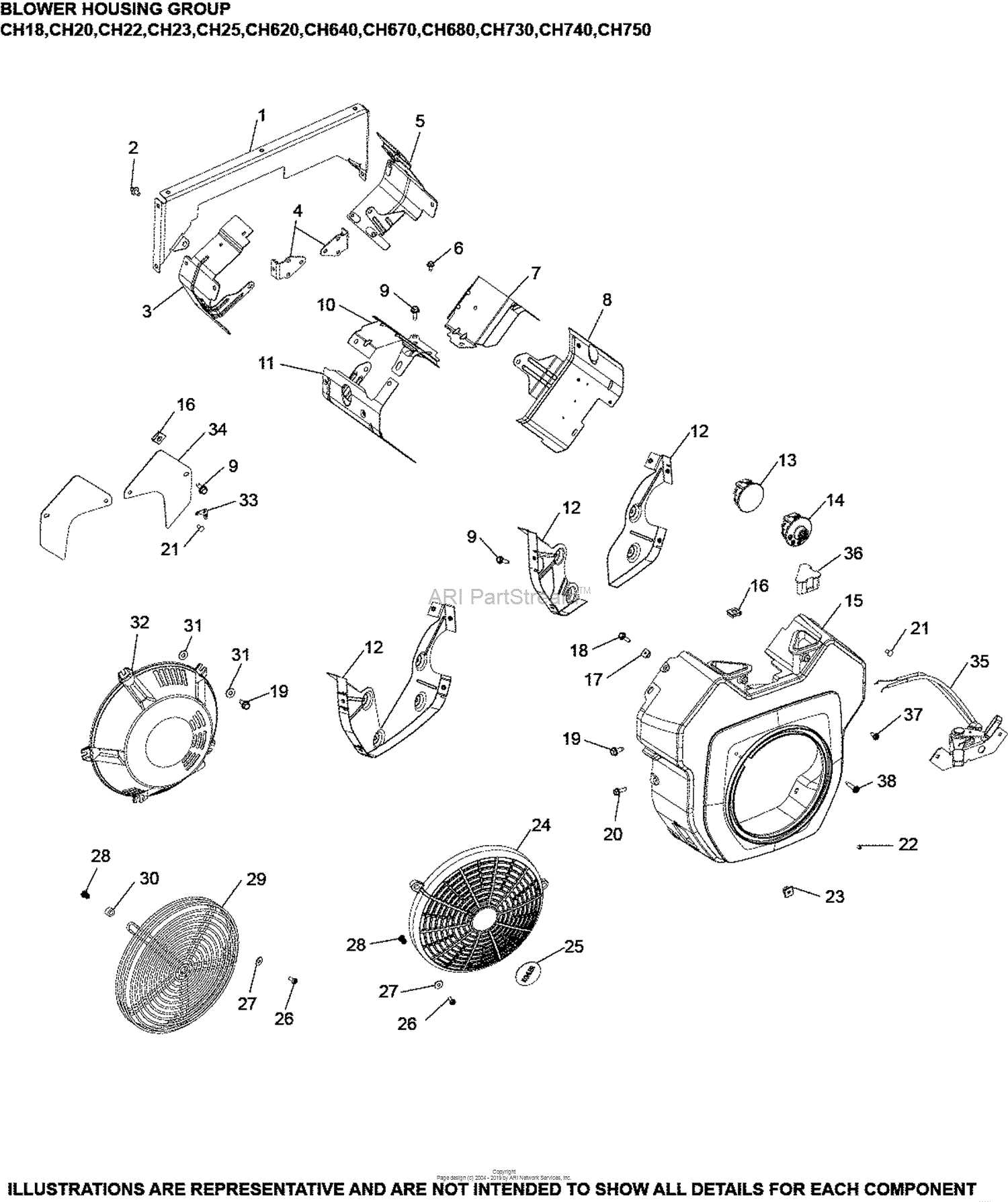

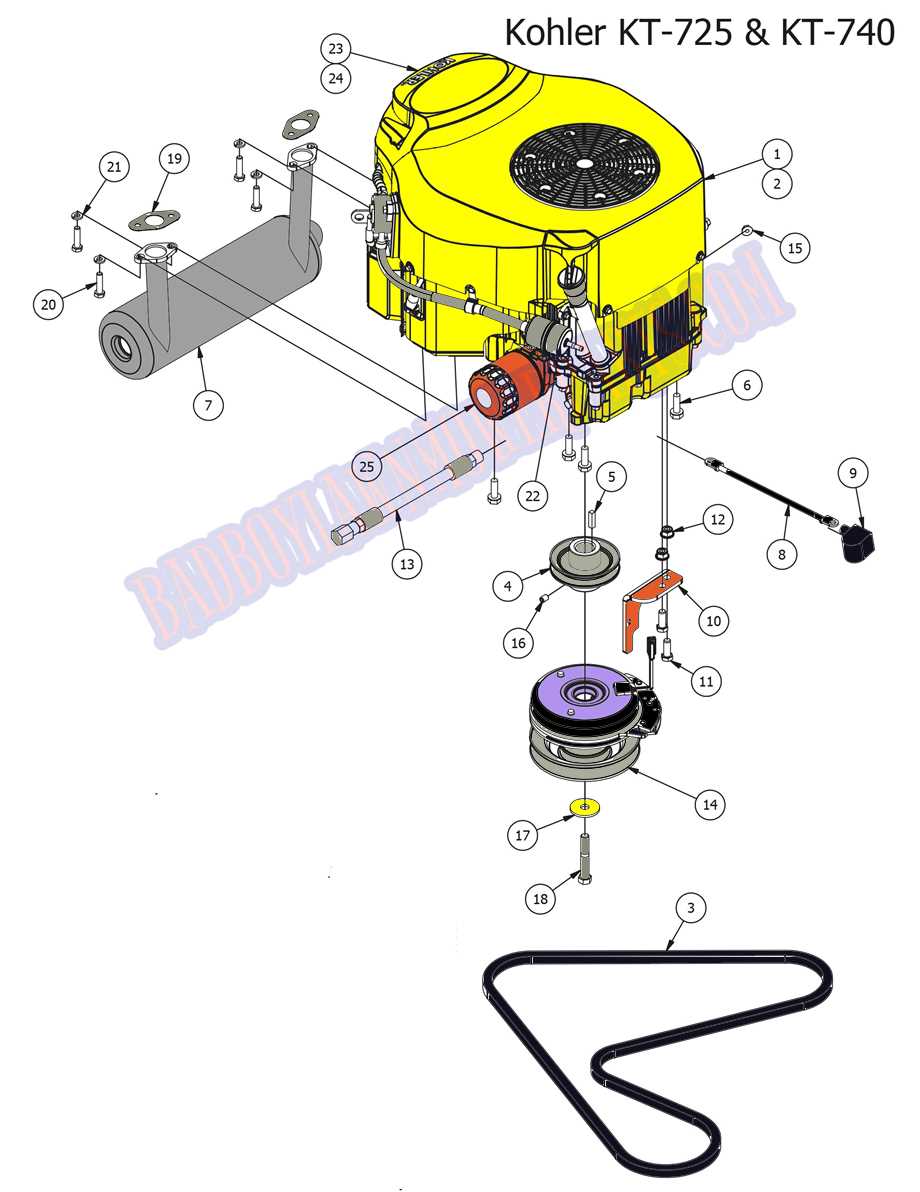

How to Use the Components Guide Effectively

Utilizing a visual reference for understanding the layout and arrangement of essential motor components can significantly improve the process of repair and maintenance. A clear and detailed guide serves as an invaluable tool, allowing users to quickly identify parts, troubleshoot issues, and ensure correct assembly during repairs.

Identifying Critical Components

Start by focusing on the key areas of the reference, such as the fuel system, ignition system, and moving parts. Understanding the relationship between these critical elements helps in diagnosing performance issues or identifying worn-out components. Pay close attention to how each part is connected and how it contributes to the overall function of the system.

Ensuring Proper Maintenance and Replacements

Once you have identified the necessary parts, the next step is ensuring correct maintenance practices. Use the guide to locate specific components for cleaning, lubrication, or replacement. This ensures that the motor continues to operate efficiently, minimizing the risk of unnecessary breakdowns.