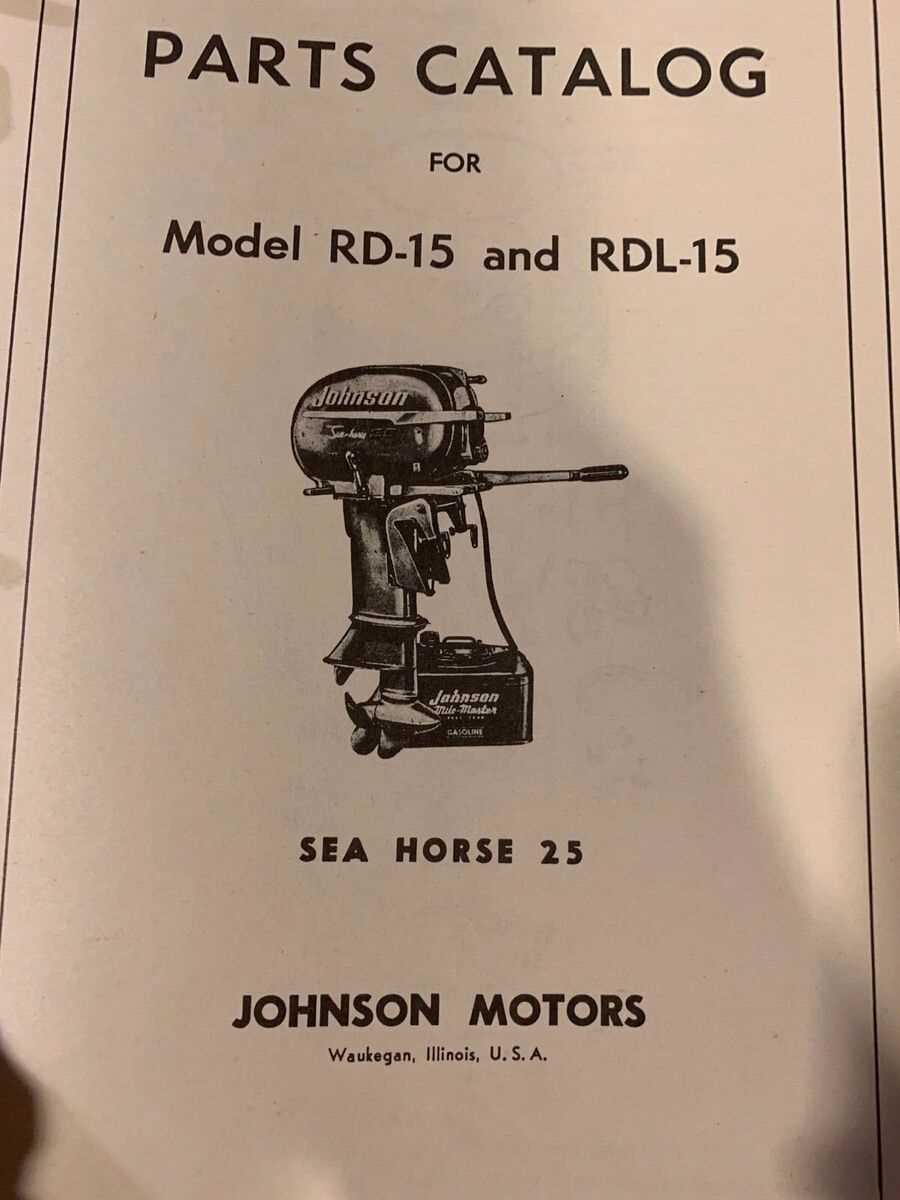

Understanding the inner workings of a small motor is crucial for ensuring its efficiency and longevity. By examining the various elements that contribute to its operation, users can perform essential maintenance and address potential issues before they become major problems. This section offers a detailed look at the different components that make up a 15 HP engine.

From the key mechanical parts to the smaller components that keep everything running smoothly, recognizing their functions is the first step in effective troubleshooting. Whether you’re looking to replace a faulty component or simply familiarize yourself with the system, understanding how everything connects is vital.

In this guide, you’ll learn how to interpret the essential technical illustrations and identify parts that need attention. Arming yourself with this knowledge will not only help maintain your motor in top condition but also make repairs more manageable and cost-effective.

Understanding the 15 HP Engine Components

Every engine is made up of several key elements, each with a specific function that contributes to the overall performance. The proper functioning of these individual components is essential for smooth operation, and recognizing them helps in keeping the engine in optimal condition. Understanding how each part works and interacts can prevent common issues and extend the lifespan of your motor.

Among the most critical sections to focus on are the mechanical elements that handle power generation and transfer. These include the fuel system, ignition components, and the drive mechanism, all of which play a role in how effectively the engine performs under various conditions. In addition, regular inspection of these systems ensures that wear and tear are caught early, reducing the likelihood of breakdowns.

By familiarizing yourself with the internal and external components, you gain a better understanding of how maintenance should be approached. With the right knowledge, even minor adjustments or repairs become less daunting, and you’ll be better equipped to maintain peak performance for years to come.

Key Parts for Maintenance and Repair

Proper maintenance of any engine involves identifying the critical components that require regular attention. These key elements are essential to ensure that the motor functions at its best and to prevent unnecessary breakdowns. Routine care of specific systems can make a significant difference in the longevity and performance of the engine.

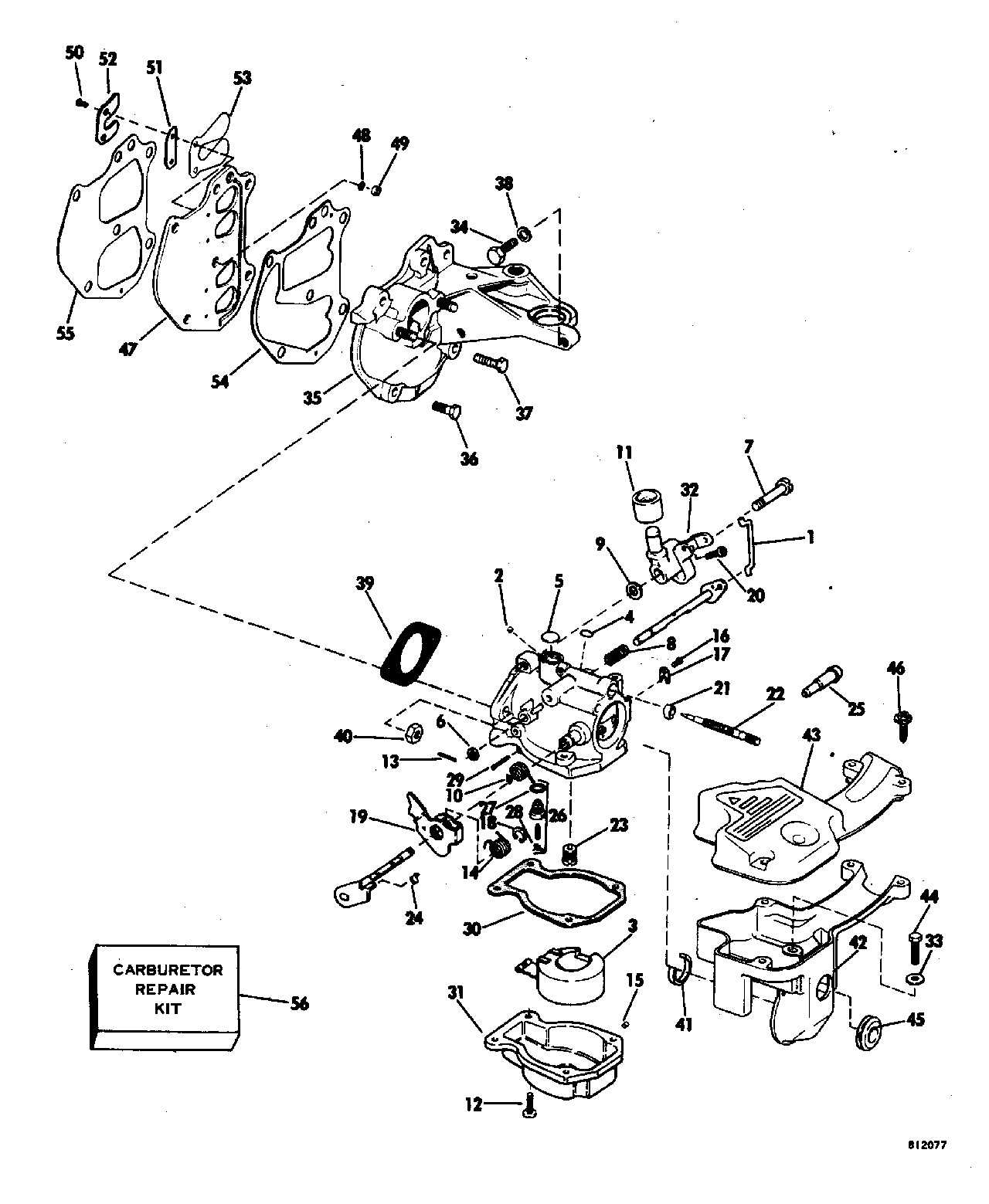

Fuel and Ignition Systems

The fuel delivery and ignition systems are two of the most vital areas to focus on for regular upkeep. These systems work together to ensure the engine starts smoothly and runs efficiently. A clogged fuel line or a worn-out spark plug can cause issues that impact overall performance, making it crucial to inspect and replace components as needed.

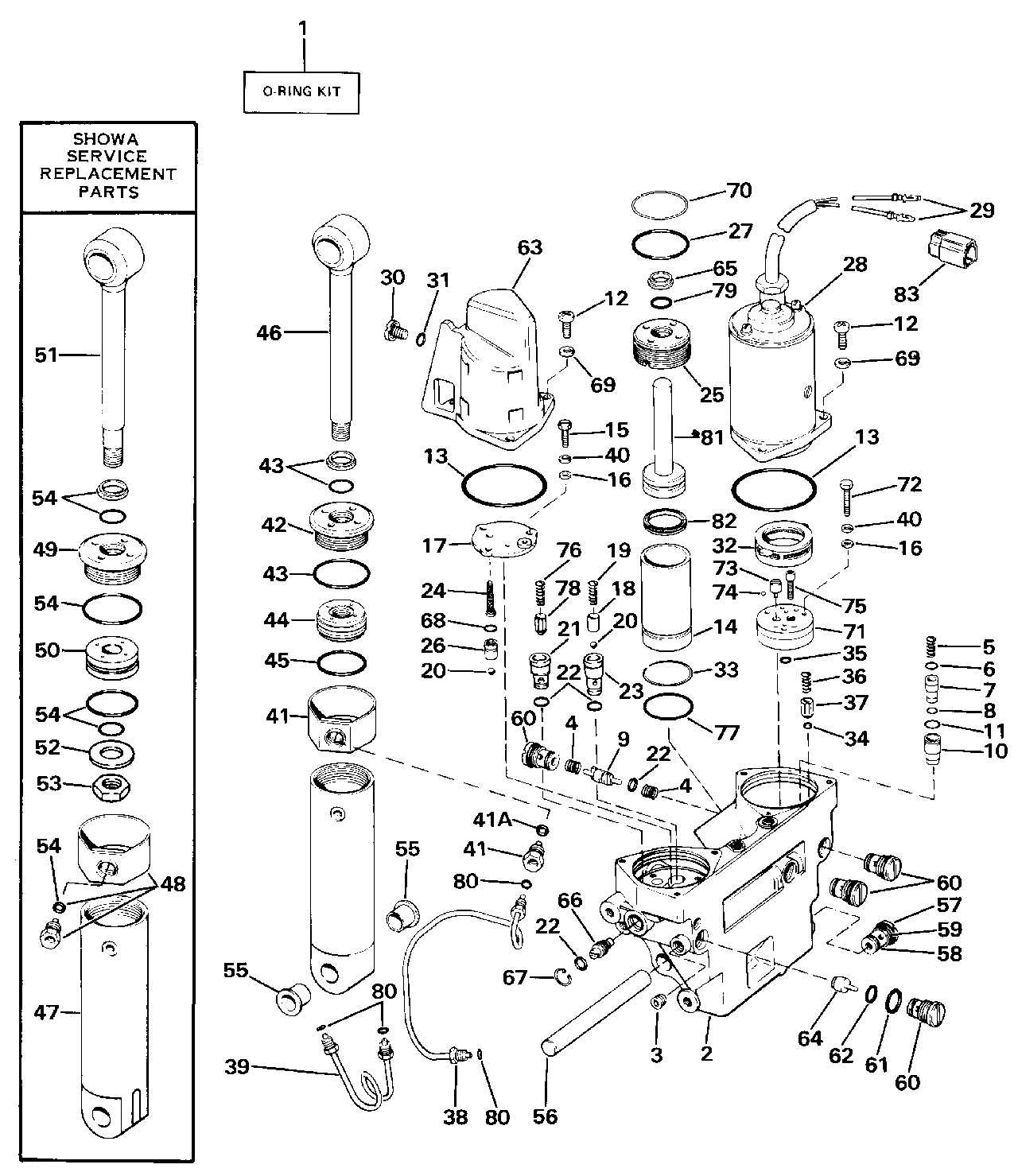

Cooling and Lubrication Mechanisms

Keeping the engine cool and properly lubricated is another fundamental aspect of maintenance. A well-lubricated system minimizes friction, preventing overheating and premature wear. Similarly, a properly functioning cooling system helps avoid engine damage due to excessive heat. Checking and maintaining these components regularly ensures smooth operation and prevents costly repairs down the line.

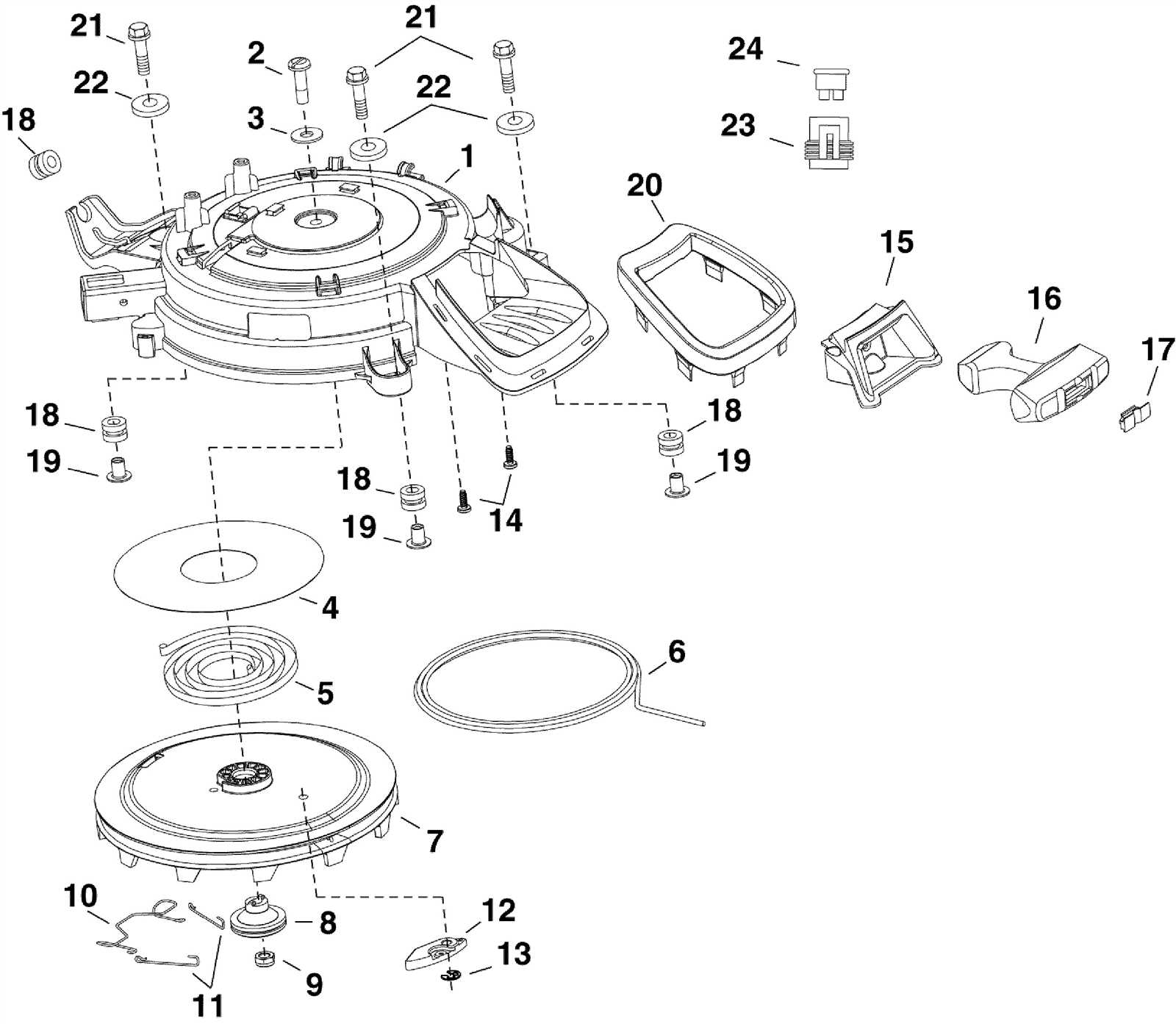

How to Read the Parts Diagram

Understanding technical illustrations is an essential skill when working with any engine. These visual guides provide a clear representation of the various components and their relationships to one another. By learning how to interpret these images, you can quickly identify the necessary elements for repair, maintenance, and assembly.

When reviewing these diagrams, pay close attention to the labels and part numbers. Each component will be clearly marked, allowing you to pinpoint exactly what you need. It’s important to familiarize yourself with the layout, as this will help you navigate the diagram effectively and make accurate repairs.