Understanding the intricate elements that make up a high-performance motor is key to proper maintenance and repairs. Each individual part plays a crucial role in ensuring the engine runs smoothly and efficiently. By breaking down the structure and functionality of these components, you can gain deeper insights into how everything works together.

Maintenance and repair tasks become much easier when you are familiar with the specific elements of the power unit. Knowing how to identify and troubleshoot common issues helps prevent costly repairs and prolongs the life of the system. This guide provides a comprehensive overview of the essential components, highlighting their roles and interconnections.

Whether you’re a professional mechanic or a car enthusiast, gaining a thorough understanding of these key elements will enhance your ability to diagnose problems and perform accurate repairs. The goal is to equip you with the knowledge to handle any situation that may arise, ensuring optimal performance for years to come.

Understanding the Chevy 350 Engine Components

Each power unit consists of a variety of essential elements, each with a unique function to ensure optimal performance. These parts must work in harmony to create the necessary power and efficiency. Gaining an understanding of their structure and function is critical for both enthusiasts and professionals alike when working on any motor.

Key Elements in the Motor

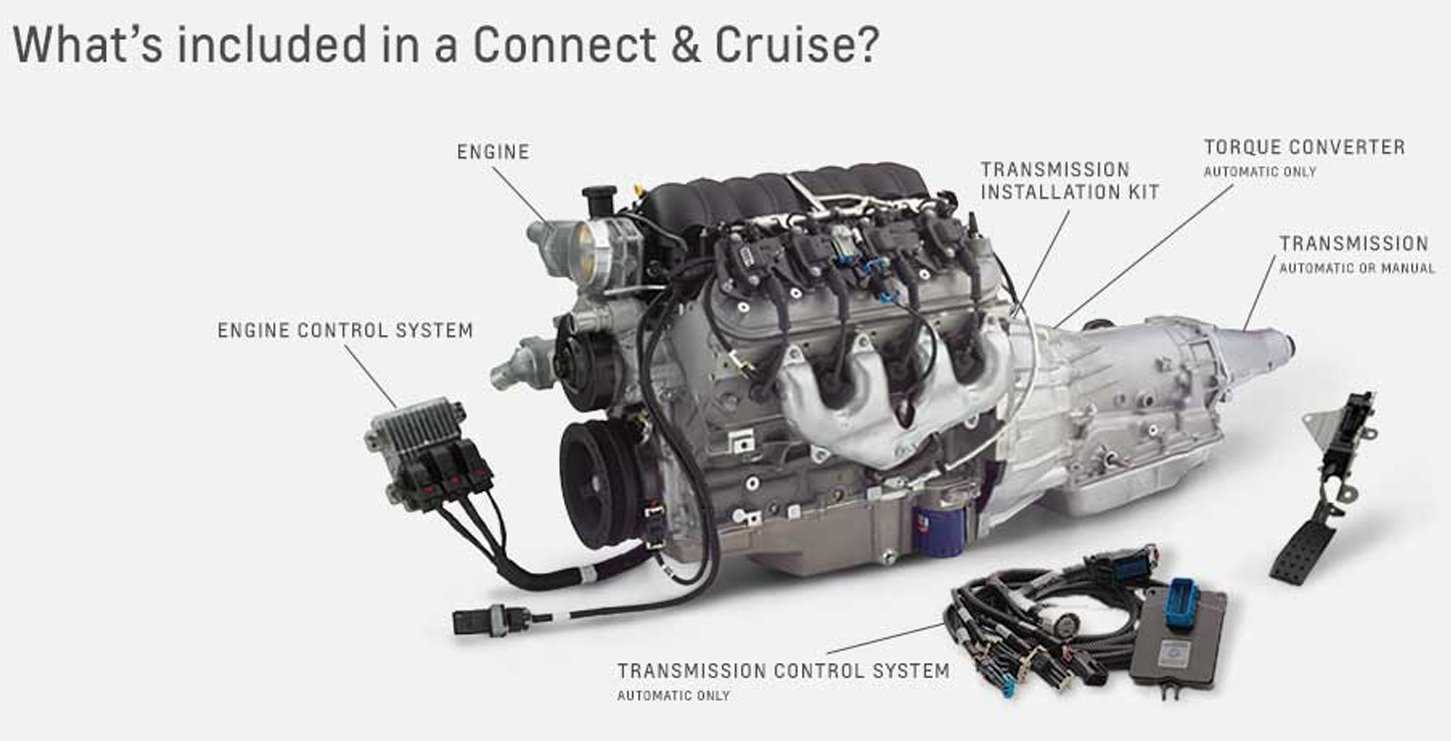

The main components can be divided into several key categories, each playing a vital role in the motor’s overall function. These include the mechanical parts, electrical systems, and cooling elements that all work together to provide smooth operation.

- Block – The central unit that houses many of the motor’s essential components.

- Pistons – These move within the cylinders to convert fuel into mechanical energy.

- Crankshaft – Transforms the up-and-down motion of the pistons into rotational force.

- Camshaft – Regulates the timing of the valves opening and closing.

- Timing Chain – Keeps the camshaft and crankshaft in sync.

Supporting Systems

Along with the core components, supporting systems are necessary to enhance the motor’s efficiency and longevity. These elements manage temperature, fuel, and exhaust to keep everything functioning at peak levels.

- Fuel System – Delivers the correct amount of fuel to the combustion chamber.

- Cooling System – Maintains the temperature of the motor, preventing overheating.

- Ignition System – Sparks the fuel mixture to initiate combustion.

- Exhaust System – Channels gases away from the motor to reduce harmful emissions.

Key Parts of the Chevy 350 Engine

Understanding the fundamental components of a motor helps in appreciating how they function together to produce power. These elements are designed to operate in precise harmony, ensuring both efficiency and reliability. The key components are engineered for durability and performance under various conditions.

Main Components of the Motor

At the core of any high-performance unit, there are several mechanical elements that play an essential role in converting fuel into power. These components work together seamlessly to ensure the motor runs smoothly and effectively.

- Block – The central structure that houses many internal parts, providing stability and strength.

- Pistons – These components move within the cylinders to create the force needed to drive the vehicle.

- Crankshaft – It transforms the linear motion of the pistons into rotational energy, driving the wheels.

- Camshaft – Regulates the opening and closing of the intake and exhaust valves to ensure proper timing.

- Valves – Control the intake of air and fuel and the expulsion of exhaust gases from the cylinders.

Supporting Systems for Optimal Performance

In addition to the core elements, there are supporting systems designed to enhance performance and extend the life of the motor. These systems regulate temperature, airflow, and fuel, ensuring everything operates within optimal conditions.

- Fuel System – Provides the proper fuel mixture for combustion in the cylinders.

- Cooling System – Maintains the motor’s temperature, preventing overheating during operation.

- Ignition System – Ignites the air-fuel mixture at the right moment for efficient combustion.

- Exhaust System – Directs harmful gases away from the engine and reduces emissions.

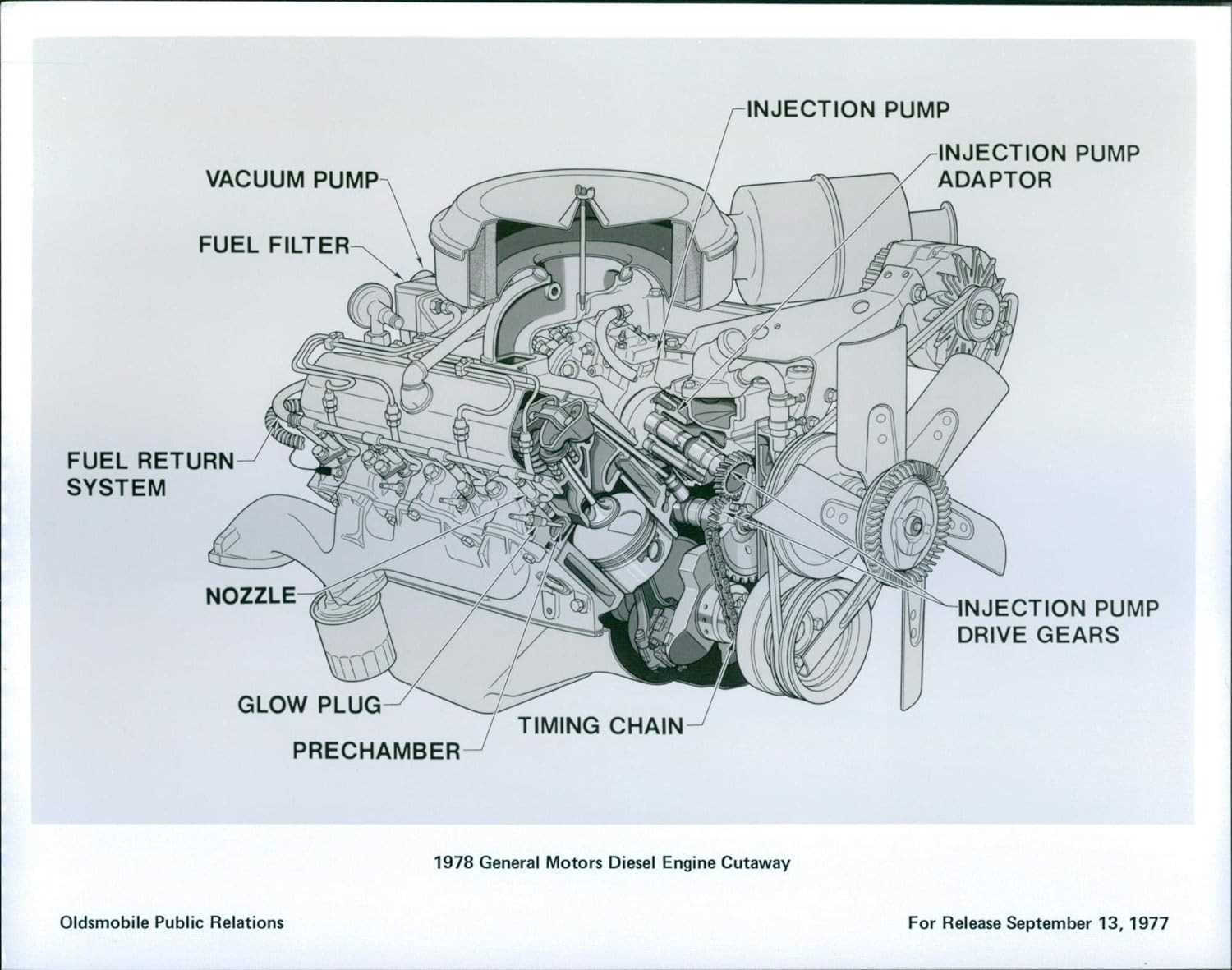

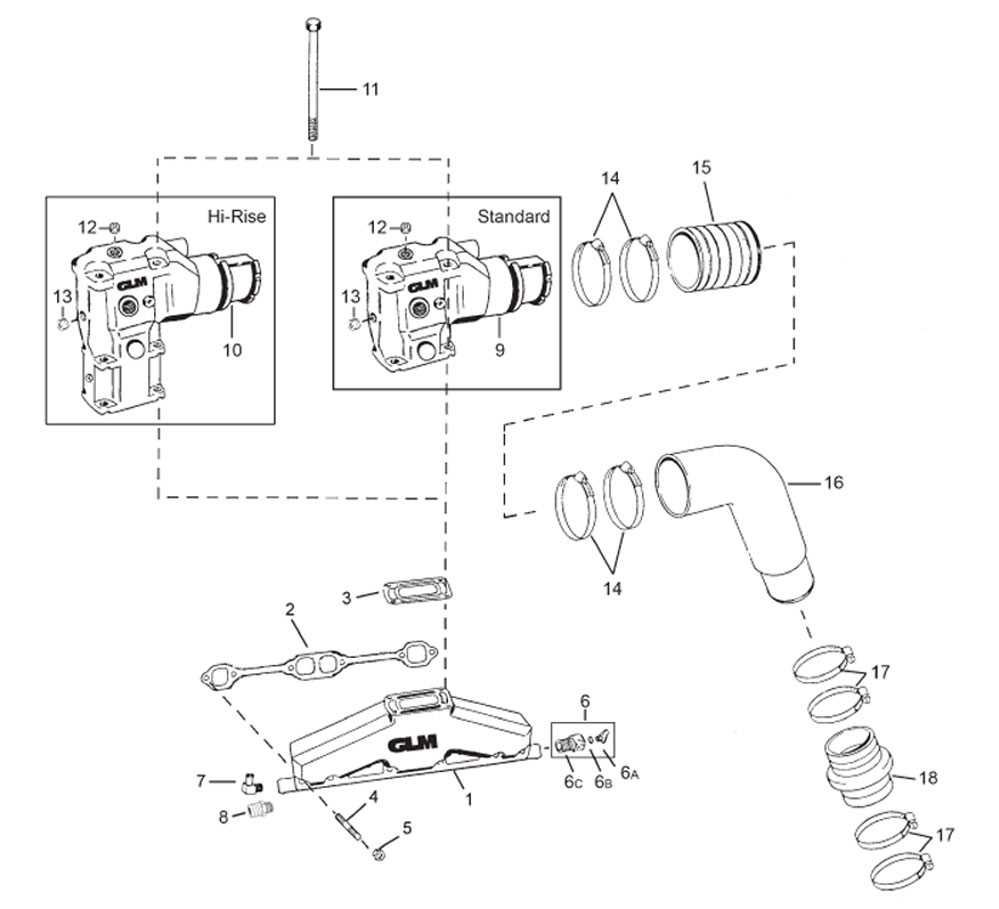

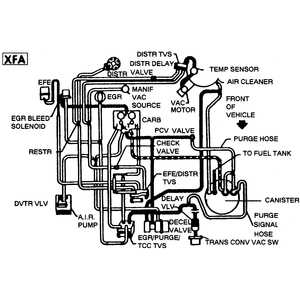

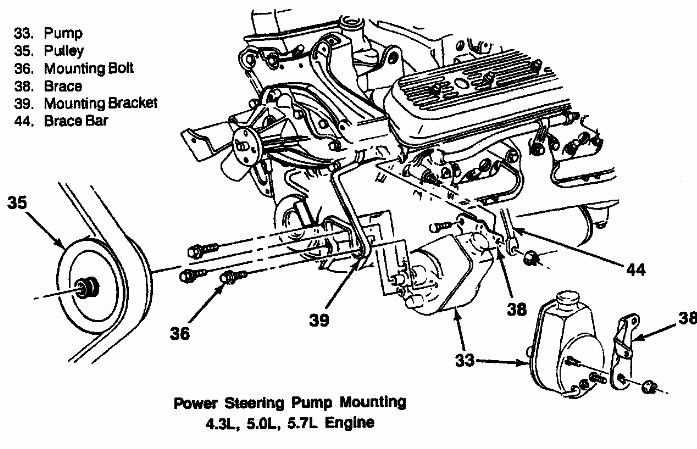

How to Read a Chevy 350 Engine Diagram

Reading a technical illustration of a motor is crucial for anyone working on repairs or upgrades. These diagrams provide a visual representation of the internal components and their relationships, offering insight into how everything fits together. Understanding how to interpret these visuals can make troubleshooting much easier and help identify specific areas for improvement.

Identifying Key Symbols and Labels

Each illustration typically uses a set of standardized symbols and labels to represent various elements. Recognizing these symbols is essential for understanding the function of each component within the system.

- Lines – Solid and dashed lines represent different connections, such as electrical or mechanical links.

- Circles and Squares – Often used to represent components like connectors, bolts, or bearings.

- Arrows – Indicate the flow of energy or fluid, such as air, fuel, or coolant, through the system.

Steps for Interpreting the Diagram

Once you’re familiar with the symbols, follow a step-by-step approach to reading the visual. Start by identifying the main assembly, then trace each component and its connections to understand how the system works as a whole.

- Start with the base structure – This often represents the main block and its internal features.

- Follow the connections – Identify how parts interact with each other, such as the movement of pistons or the timing of valves.

- Look for key annotations – Detailed notes often provide additional context or instructions related to maintenance or assembly.