When maintaining complex machinery, it’s crucial to have a clear understanding of its internal structure. Identifying the key elements that make up the system ensures proper care, quick troubleshooting, and more efficient repairs. This guide will provide an overview of the core components, their functions, and how they interconnect to keep your equipment running smoothly.

Knowing the layout of your machine allows you to spot wear and tear early. By examining the different units and understanding their role, you can perform preventative maintenance before a small issue becomes a larger problem.

Whether you’re a seasoned mechanic or a beginner, using an accurate visual representation is invaluable for successful repairs. With the right resources, you can save time, reduce costs, and improve overall performance by addressing issues promptly.

Understanding the Ford 1710 Tractor Components

In order to keep any complex machinery operating at its best, it is essential to understand the various elements that make up the system. Each component plays a significant role in the overall function, and knowing how they work together can help with maintenance and troubleshooting. This section aims to provide a clear understanding of the crucial parts and their interconnections.

Key Elements of the System

The core components of any machine include the engine, transmission, and hydraulic system. Each part has a unique function that directly affects the performance of the equipment. The engine provides the power necessary for operation, while the transmission ensures that power is properly distributed. The hydraulic system, on the other hand, allows for smooth movement and operation of key mechanical parts.

Importance of Regular Inspection

Regular inspection of these components is critical for avoiding unexpected breakdowns. Understanding the function and placement of each element allows you to identify early signs of wear or malfunction. Timely repairs and proper maintenance can extend the life of the equipment, reduce costly repairs, and enhance its overall efficiency.

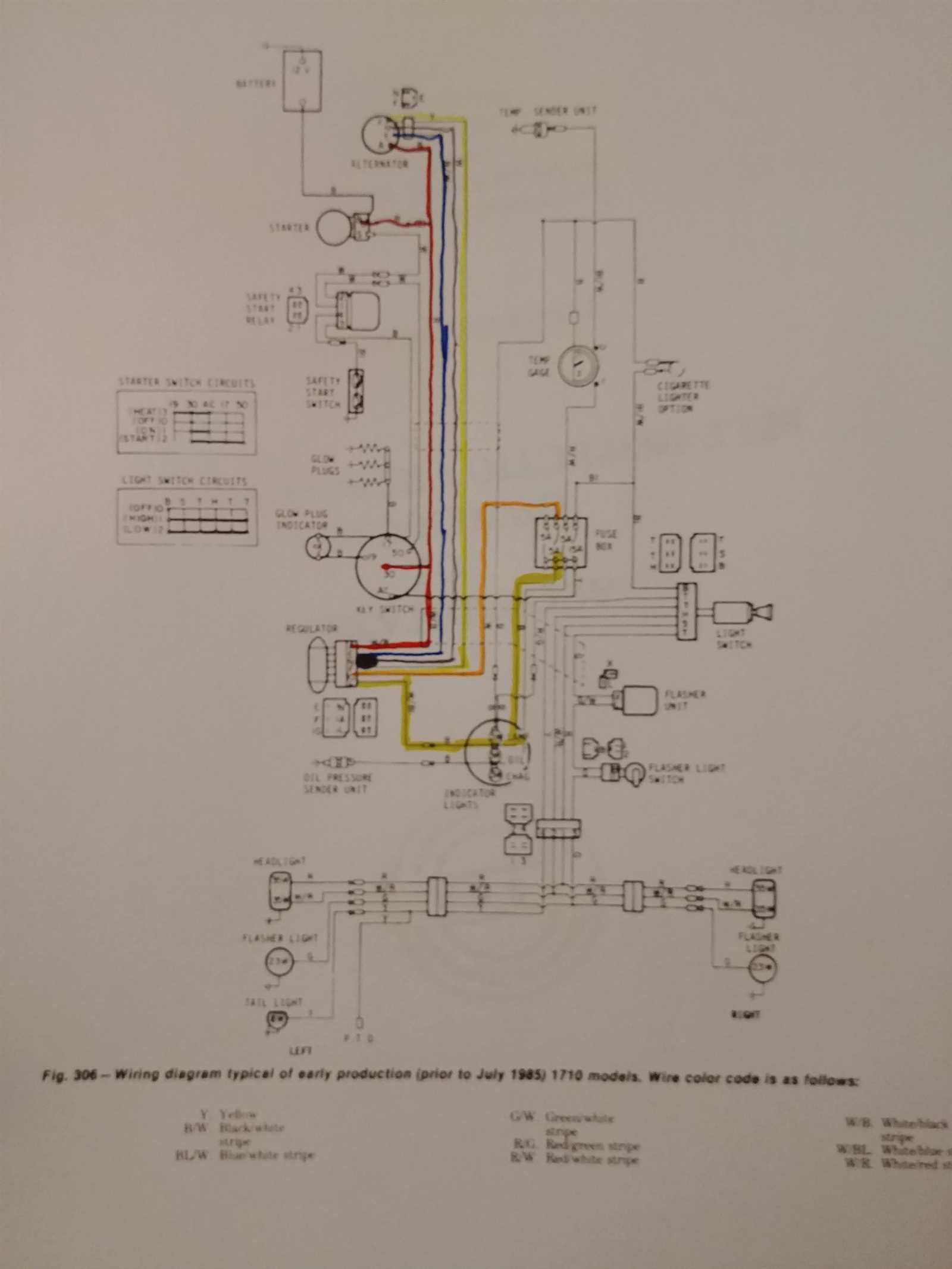

Identifying Key Parts in the Diagram

Understanding the layout of a machine requires recognizing its essential components and how they interact. A clear representation can help pinpoint each part’s location and function, making repairs and maintenance much more manageable. In this section, we will explore the key elements that should be identified in any schematic representation.

Main Power Components

The primary units responsible for driving the system are the engine and transmission. The engine generates the power necessary for operation, while the transmission system channels and regulates the distribution of that power to other parts. Identifying these components in the schematic is essential for troubleshooting any performance issues or breakdowns.

Supporting Systems and Structures

In addition to the power components, the hydraulic system and steering mechanisms play a critical role in ensuring smooth functionality. These systems help control movement and precision. Recognizing their layout allows you to identify potential issues in movement control and other mechanical functions, enabling more effective maintenance.

Step-by-Step Guide for Tractor Repairs

When performing repairs on any piece of machinery, having a clear, organized approach is crucial. A systematic method not only ensures that all aspects are addressed but also helps avoid unnecessary errors. This guide provides a detailed, step-by-step process to follow for effective repairs and maintenance.

Preparing for the Repair

Before starting any repair, it’s essential to gather the necessary tools and materials. Here’s a quick checklist to ensure you’re fully prepared:

- Correct set of wrenches and screwdrivers

- Replacement parts (if needed)

- Safety equipment, including gloves and goggles

- Clean workspace with ample lighting

Once you have everything in place, make sure to disconnect any power sources to avoid accidents during the repair process.

Repair Process

Follow these steps to troubleshoot and fix common issues:

- Diagnose the problem: Review the machine’s symptoms to identify which component may be malfunctioning.

- Disassemble the necessary parts: Use your tools to carefully remove any parts that need inspection or replacement.

- Inspect and replace faulty components: Check each part for wear and tear. Replace any components that are damaged or worn out.

- Reassemble the system: Once the faulty parts are replaced, carefully put everything back in place, ensuring all connections are secure.

- Test the machine: After reassembling, perform a test to ensure the repair was successful and the equipment operates properly.

By following these simple steps, you can ensure that your machine continues to run smoothly and efficiently for years to come.