When it comes to maintaining and repairing your equipment, knowing the essential elements inside the device is crucial. Familiarizing yourself with its various components ensures smooth operation and helps prevent costly errors during repairs. Identifying each part correctly can significantly reduce downtime and improve overall performance.

Knowing where each piece fits allows for easier troubleshooting and part replacements. With proper understanding, you can make informed decisions and keep your tool running efficiently for longer periods. A clear guide to each section will help you grasp the interconnections and functionality of each element.

Whether you’re a DIY enthusiast or a professional, having a detailed map of the inner workings helps streamline the repair process. Understanding these vital pieces ensures you can perform maintenance tasks with confidence and minimize the chances of damage during fixes.

Understanding the Components of Ryobi Chainsaw

To ensure the smooth operation of any tool, it is important to have a thorough understanding of its individual elements and how they work together. Each component plays a key role in the overall function and performance, making it essential to familiarize yourself with their design and purpose.

The main sections of the tool are typically divided into the power unit, the cutting mechanism, and safety features. Recognizing how each part interacts helps prevent damage during repairs or maintenance, allowing for a more efficient approach when tackling any issues.

By understanding the layout and structure, you can easily pinpoint any potential problems. Knowing the specific functions of the major sections will help you identify worn-out or broken components, enabling quicker fixes. This knowledge also provides confidence when ordering replacement elements, ensuring you get the correct parts for your device.

How to Identify Ryobi Chainsaw Parts

Recognizing the various components of your tool is the first step towards efficient maintenance and repairs. By understanding each piece’s function and appearance, you can easily spot any issues and make necessary adjustments or replacements.

Recognizing Key Components

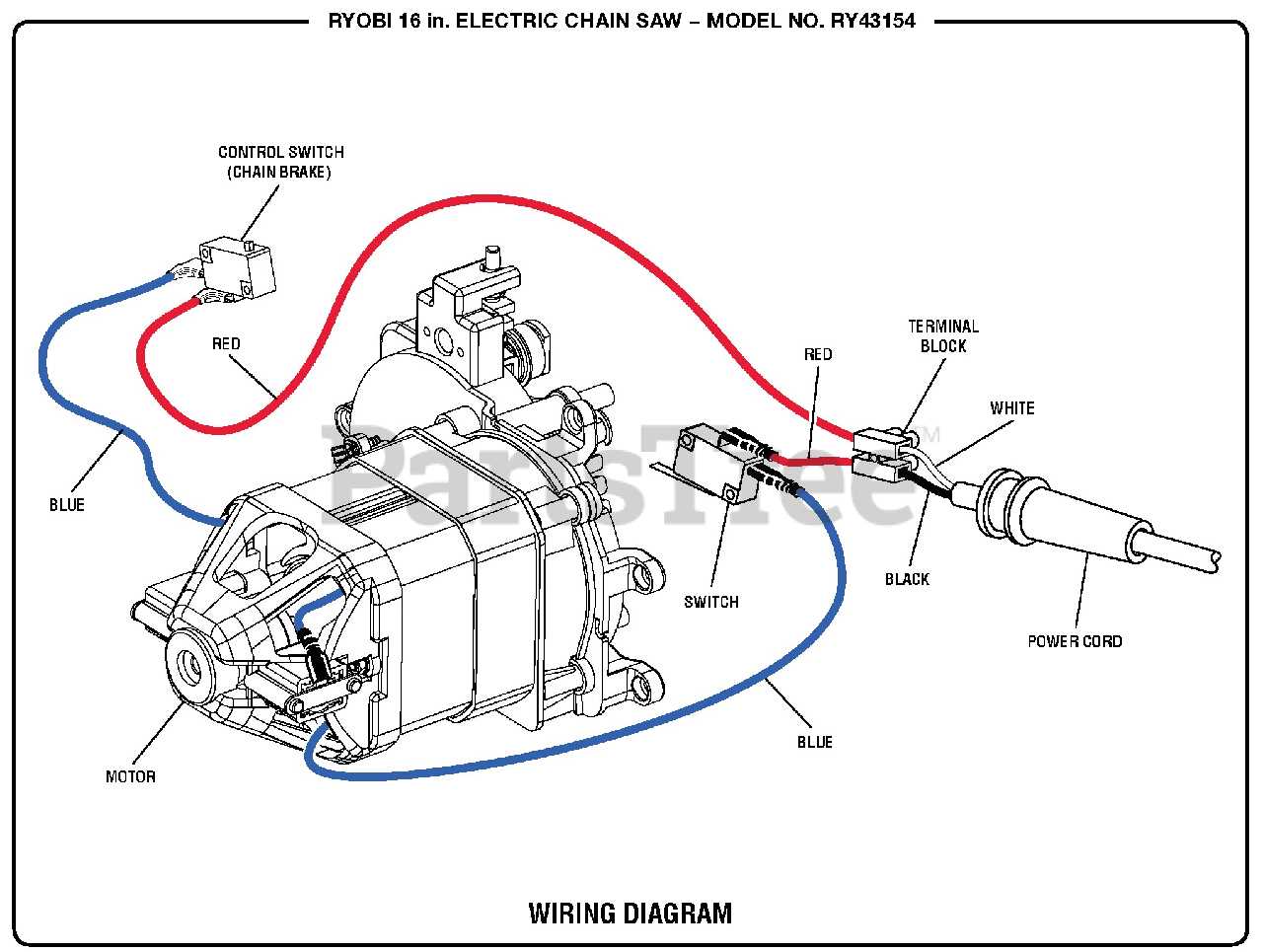

Begin by familiarizing yourself with the main sections of the device. These typically include the motor housing, cutting elements, and safety features. Each section is designed with distinct characteristics, such as specific shapes or colors, to make identification easier. Checking these areas first will help you identify the most important elements of your equipment.

Using Reference Guides

Utilizing reference materials, such as detailed schematics or product manuals, is crucial for precise identification. These guides provide clear images and descriptions of each component, helping you distinguish between similar-looking parts. Make sure to refer to these resources whenever you need to confirm the identity of a part before replacing or repairing it.

Step-by-Step Guide to Parts Replacement

Replacing components in your tool requires careful attention to detail and following the correct procedure to ensure proper function. By following a methodical approach, you can efficiently swap out old or damaged parts without causing further issues. This guide will take you through the essential steps for a smooth replacement process.

- Turn off the power – Before you begin, ensure the device is powered off and disconnected from any power source to avoid accidents.

- Gather the necessary tools – Depending on the component you’re replacing, you may need specific tools like screwdrivers, wrenches, or pliers. Prepare everything beforehand to save time.

- Locate the damaged component – Inspect the device carefully and identify the part that needs replacing. Make sure it is clearly marked or referenced in the product manual.

- Remove the faulty component – Unscrew or unclip the damaged part, taking note of how it is attached. Keep any screws or fasteners organized for reassembly.

- Install the new component – Place the new piece in the same position as the old one, ensuring a secure fit. Use the same screws or fasteners to reattach it.

- Test the device – After replacing the part, power on the tool and test its performance. Ensure everything works as expected before returning it to regular use.

By following these steps, you can ensure the safe and effective replacement of essential components, extending the life of your equipment and improving its overall performance.