Having a clear understanding of the components that make up your cleaning device can significantly enhance your maintenance and repair skills. Knowing where each piece fits and how they interact is key to ensuring your machine runs smoothly for years. In this guide, we’ll take a closer look at the essential elements of the appliance, breaking down its structure and explaining each section’s function.

Whether you’re trying to troubleshoot an issue or simply perform regular upkeep, understanding the layout of the various components will make the process easier. Familiarizing yourself with the different parts allows for quicker identification of any malfunctions or areas that need attention.

By gaining insight into the design and function of each component, you will be better equipped to make informed decisions about repairs or replacements. This knowledge can ultimately extend the life of your equipment, keeping it in optimal condition for longer.

Understanding Dyson Stick Vacuum Components

Every cleaning device is made up of several crucial elements that work together to deliver optimal performance. Understanding the function of each component is essential for proper care, efficient troubleshooting, and effective maintenance. Each part of the machine plays a unique role, whether it’s for suction, filtration, or maneuverability. By gaining an in-depth knowledge of these individual pieces, users can ensure that the appliance operates at its best for an extended period.

Key Elements of the Cleaning Device

The central body of the machine houses the motor, which is responsible for generating the suction power that drives the entire cleaning process. Connected to this motor, the filtration system ensures that dust and particles are trapped and not released back into the air, contributing to a cleaner environment. Additionally, the handle and wand components offer ease of use, allowing users to reach different surfaces and corners without straining their hands or back.

Understanding the Attachments and Accessories

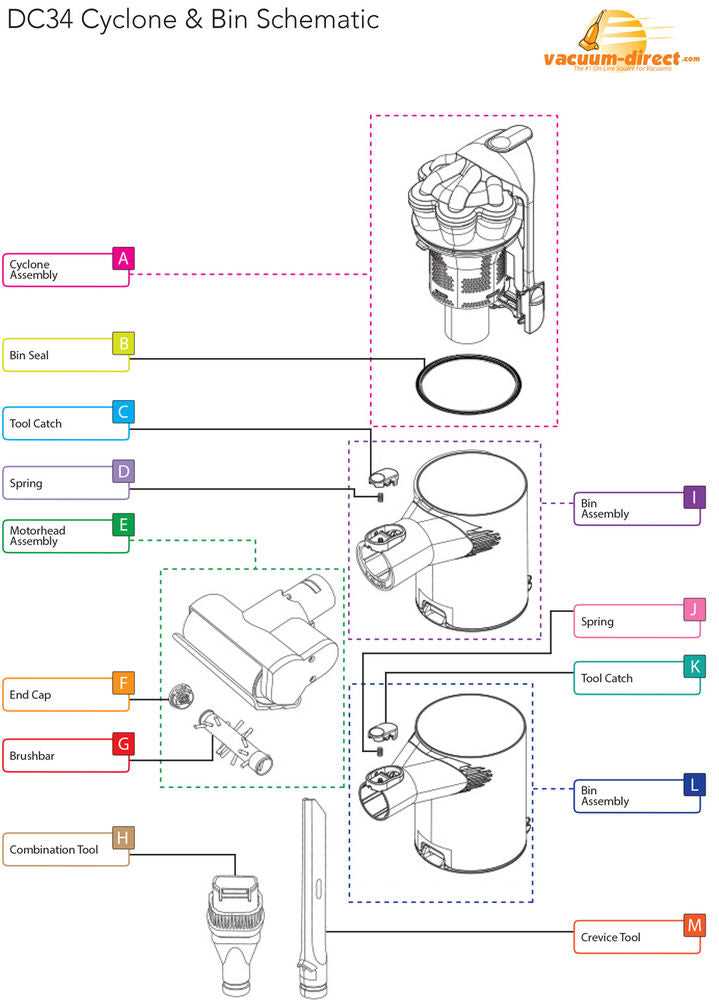

Attachments such as brushes, nozzles, and crevice tools are designed to handle specific cleaning tasks, from tackling carpets to cleaning hard-to-reach places. These accessories add versatility to the machine, making it more adaptable for various cleaning needs. Over time, these parts may require cleaning or replacement, so recognizing their function helps users determine when maintenance is necessary.

How to Identify Dyson Vacuum Parts

Being able to recognize the various components of your cleaning device is essential for both maintenance and repair tasks. Each element has a specific function, and understanding where they fit into the overall structure can save you time and effort when troubleshooting. Identifying these components allows you to pinpoint the source of any issues and helps in determining what needs cleaning, repairing, or replacing.

Begin with the main body, which contains the motor and suction system. This is the heart of the machine, and it’s where most of the power is generated. By recognizing this section, you can quickly assess the health of the motor and determine if further investigation is needed.

Next, look at the extension rod and handle, which allow for ease of movement and maneuvering. These are typically lightweight yet durable, making them essential for comfortable use. Inspect these pieces to ensure they are secure and free from damage.

Attachments are often the most versatile components and can be swapped out based on the surface you’re cleaning. Familiarizing yourself with different brushes, nozzles, and specialized tools will make it easier to adapt the machine to various tasks. Be sure to examine these accessories regularly for wear and tear.

Maintenance Tips for Dyson Stick Vacuums

Regular upkeep is crucial to ensure that your cleaning device performs efficiently over time. By adopting a few simple maintenance practices, you can extend the lifespan of your machine and prevent common issues from arising. Proper care not only helps maintain optimal functionality but also reduces the need for costly repairs or replacements.

One of the most important aspects of maintenance is keeping the filter clean. Over time, dust and debris can clog the filtration system, reducing the suction power and efficiency. Clean the filter regularly, following the manufacturer’s instructions, to ensure that the airflow remains unobstructed and the air quality stays high.

Check the brushes and rollers for hair or debris buildup, which can cause them to lose effectiveness. Removing hair strands and dirt from these components will improve their performance, especially on carpeted surfaces. Periodically inspect the attachments and nozzles to ensure they are securely attached and in good condition.

Another key maintenance tip is to empty the dust canister frequently. A full canister reduces suction efficiency and can make the machine harder to maneuver. Empty it after every use or when it reaches the maximum fill line to keep the device running smoothly.