Maintaining industrial equipment in optimal condition requires a clear understanding of its internal structure and how each element functions. Knowing how to troubleshoot and replace specific components is essential for ensuring longevity and performance. This section will guide you through the essential parts and how to approach repairs effectively.

With the right knowledge, diagnosing issues becomes easier, and the need for professional help can be minimized. Whether you’re handling malfunctions or performing regular checks, understanding the layout and roles of individual components will give you confidence to manage the situation.

Regular maintenance is key to avoiding unexpected breakdowns and costly repairs. By familiarizing yourself with the various sections of the equipment, you can quickly identify worn-out or damaged elements that need attention. Prevention is always better than cure when it comes to machinery upkeep.

Understanding Equipment Components

When managing any mechanical system, it’s crucial to understand the role and interaction of each component within the structure. A comprehensive knowledge of these elements allows for smoother troubleshooting, efficient repairs, and a better overall understanding of how the system operates. Identifying how different parts work together helps prevent unnecessary issues and enhances the performance of the equipment.

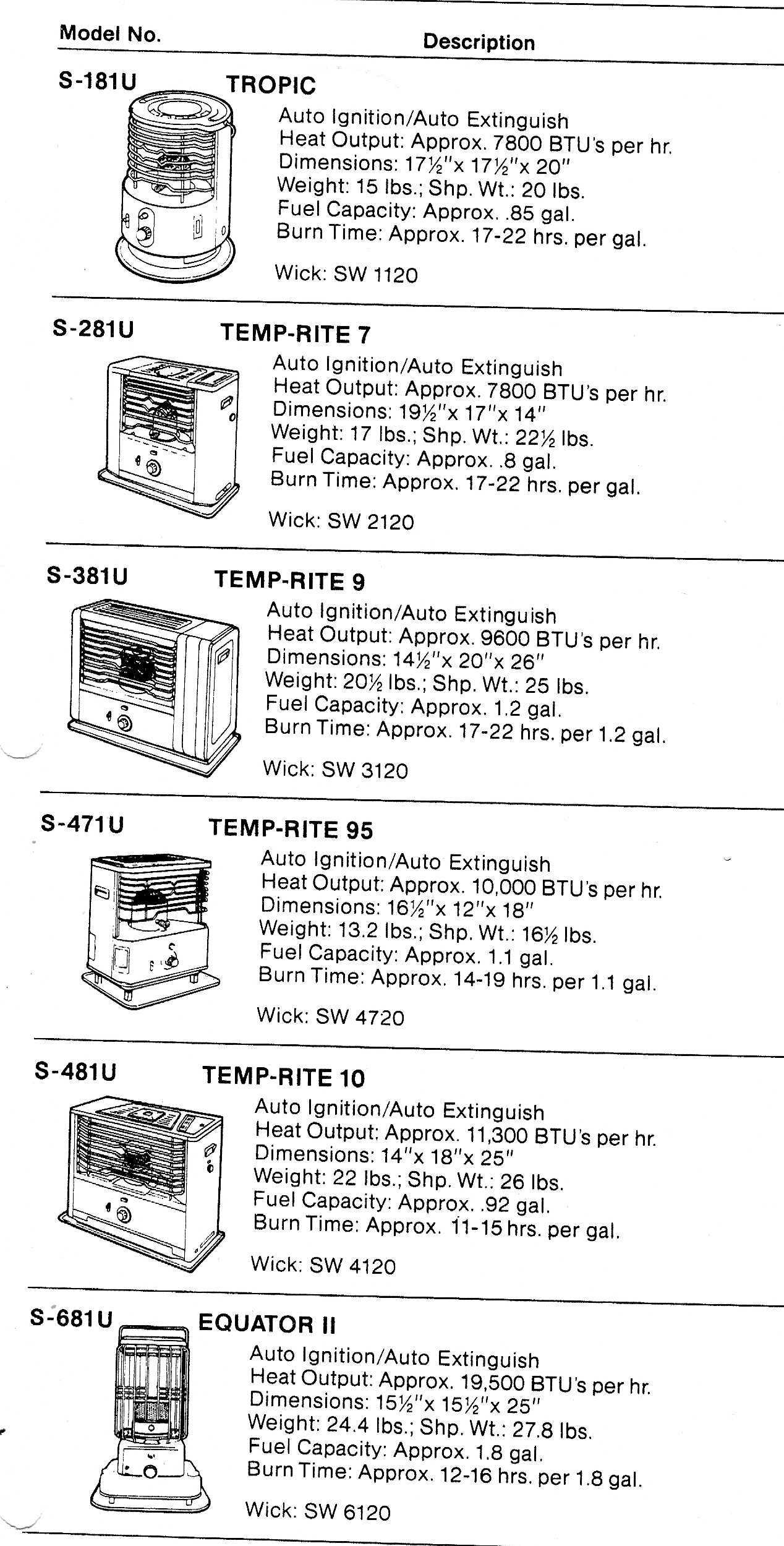

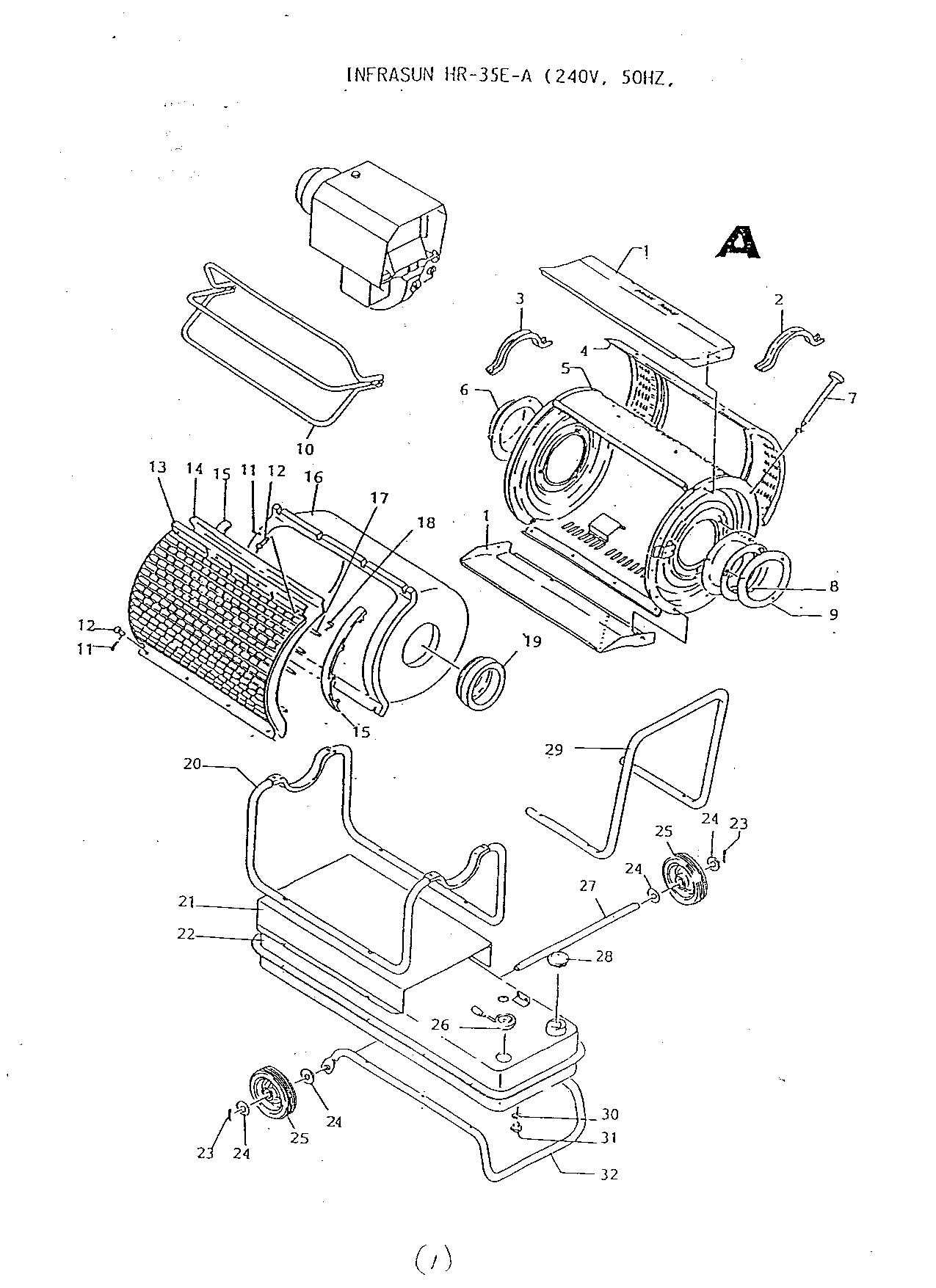

Every machine consists of several integral components, each with a specific function that contributes to the overall efficiency of the unit. Recognizing the main elements, such as the power supply, combustion system, and airflow mechanisms, is essential for anyone looking to maintain or repair the equipment. Familiarizing yourself with the layout of these components allows for quicker problem identification and streamlined maintenance processes.

Routine inspection and awareness of potential weak points are important for ensuring that all components are functioning as expected. Regularly checking key areas can help detect early signs of wear or damage, leading to more timely repairs and avoiding larger, costlier breakdowns. Understanding each part’s contribution to the whole system ensures long-term reliability and performance.

How to Identify Key Components

Recognizing the essential components of a machine is a critical first step in any maintenance or repair task. By understanding where each part is located and how it functions, you can quickly diagnose problems and determine which elements need attention. Familiarizing yourself with these key components ensures smoother operation and helps extend the equipment’s lifespan.

Start by locating the power and fuel systems, which are often the primary areas that require maintenance. These include the fuel tank, ignition system, and energy sources, which work together to power the unit. Next, identify the airflow components, such as fans or vents, which play a crucial role in ensuring the proper functioning of the machine by regulating temperature and airflow.

Finally, focus on the structural elements like the casing and internal chambers. These parts not only provide structural integrity but also house other vital mechanisms. Recognizing the layout of these components will help you determine which sections are more prone to wear and tear, allowing you to proactively address potential issues before they affect performance.

Common Issues and Solutions

Like any mechanical system, equipment can experience a range of common problems that affect its performance. Identifying these issues early on allows for quicker resolutions and minimizes downtime. Understanding typical malfunctions and knowing the appropriate solutions is key to maintaining smooth operation and preventing costly repairs.

Overheating and Fuel Flow Problems

One of the most frequent issues is overheating, which can be caused by a variety of factors including clogged vents, dirty filters, or a malfunctioning thermostat. To resolve this, regularly clean and inspect the airflow components and ensure that the fuel supply is consistent. If overheating persists, check for damaged seals or hoses, which could cause leaks and disrupt proper functioning.

Ignition Failures

Another common issue involves ignition problems, which can occur due to faulty spark plugs or issues with the ignition system. Regularly checking and replacing spark plugs can prevent such failures. In addition, ensure that the power source is stable and the electrical connections are secure. If problems continue, further inspection of the ignition control board may be necessary to identify underlying faults.