Proper maintenance of mechanical devices requires a clear understanding of their internal structures. Knowing the layout and function of each individual part is essential for troubleshooting and repairs. With the right knowledge, you can ensure your machine operates at its peak performance, extending its lifespan and avoiding costly downtime.

In this guide, we will explore how to interpret a technical map of your machine, which serves as a blueprint for identifying each element. Whether you’re looking to replace a faulty component or just conducting routine maintenance, having a solid grasp of how the parts interact will make the process much easier.

Familiarizing yourself with these details will not only help you diagnose issues quickly but also provide insight into how to prevent future breakdowns. With clear instructions and helpful tips, you’ll be well-equipped to handle any challenges that arise. Empower yourself with knowledge and take control of your equipment’s health.

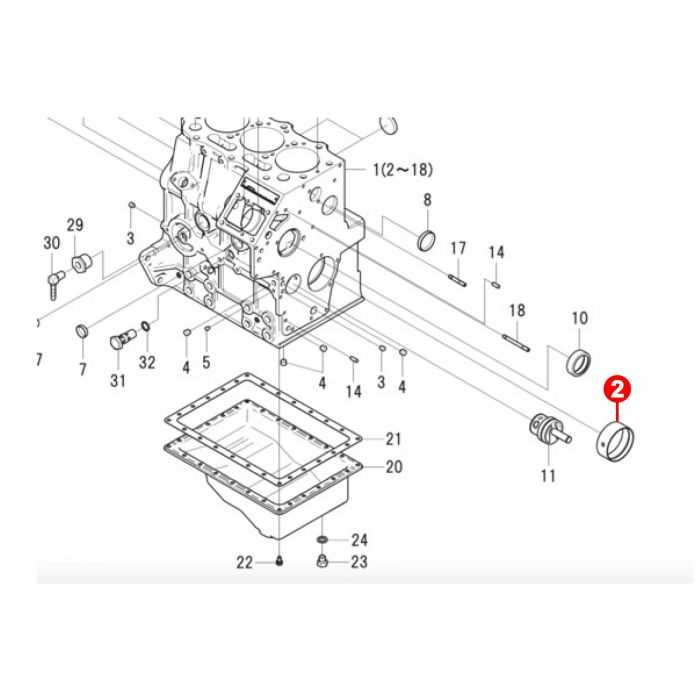

Understanding the Princeton PB50 Components

For effective maintenance and repair, it’s crucial to grasp how the internal components of a machine work together. Each element has a specific function that contributes to the overall performance of the system. By familiarizing yourself with these parts and their relationships, you can troubleshoot and resolve issues with greater efficiency.

Key Elements and Their Functions

Every device consists of several core components that play distinct roles. Some parts are responsible for powering the system, while others provide support or control specific functions. Understanding how each part operates within the machine’s structure will help you identify potential issues quickly.

How to Identify Faulty Components

Recognizing malfunctioning components is an essential skill. Certain signs, such as unusual sounds, performance drops, or visible damage, can indicate which part needs attention. Familiarity with the device’s layout will allow you to pinpoint the problem area and take appropriate action, whether it’s a simple repair or a more complex replacement.

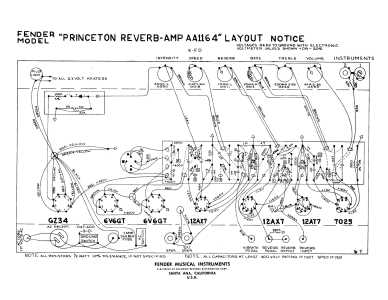

How to Read the PB50 Parts Diagram

Understanding technical illustrations is essential for anyone involved in the repair or maintenance of complex machinery. These visual guides provide a detailed map of the system, allowing you to easily identify each element and its placement. By interpreting these visuals correctly, you can locate and address issues more effectively.

Interpreting Symbols and Labels

In technical illustrations, symbols and labels represent the various components and their connections. Each symbol typically corresponds to a specific part, while labels provide further details, such as part numbers or material specifications. Learning how to decode these symbols is the first step in gaining a comprehensive understanding of the system’s structure.

Following the Layout for Maintenance

The layout of these illustrations often reflects the physical arrangement of the components. By following the flow from one part to another, you can trace how the system works as a whole. Taking the time to study the map will allow you to pinpoint areas that may need attention and ensure that maintenance is performed accurately and efficiently. Familiarity with this layout is key to effective troubleshooting.

Common Issues and Solutions for PB50 Parts

Machines can encounter a range of problems as they age or experience wear and tear. Understanding the most frequent issues with their components allows for quicker identification and more effective repairs. By knowing the typical faults that arise, you can address them with appropriate solutions before they escalate into more serious problems.

Identifying Worn or Damaged Elements

One of the most common issues is the gradual deterioration of key components. Over time, certain parts may become worn out due to continuous use, resulting in poor performance or failure to function. Regular inspections will help you spot signs of wear such as cracks, leaks, or unusual noises, allowing for timely replacements to maintain the system’s efficiency.

Handling Performance Drops

If you notice a decrease in the system’s overall performance, it could be caused by a variety of issues, such as a misaligned or malfunctioning component. In many cases, cleaning or recalibrating the affected parts can restore functionality. However, persistent performance problems may require replacing specific elements that are no longer operating optimally.