When maintaining or repairing a small power generator, it’s crucial to have a clear understanding of its internal structure. A well-detailed reference guide can significantly ease the identification of individual elements, making troubleshooting and maintenance more manageable. By knowing the layout of these essential parts, users can ensure their device runs smoothly for longer periods.

In this guide, we will explore the core elements of a common portable generator model, breaking down each section and providing valuable tips for routine checks. Whether you’re replacing a faulty component or simply trying to familiarize yourself with the equipment, understanding these parts will save both time and effort.

Efficiency and reliability are essential when it comes to running a generator, and knowing the role each part plays can help you address issues before they become major problems. Whether you’re a novice or experienced, this detailed overview will help you keep your equipment in top condition.

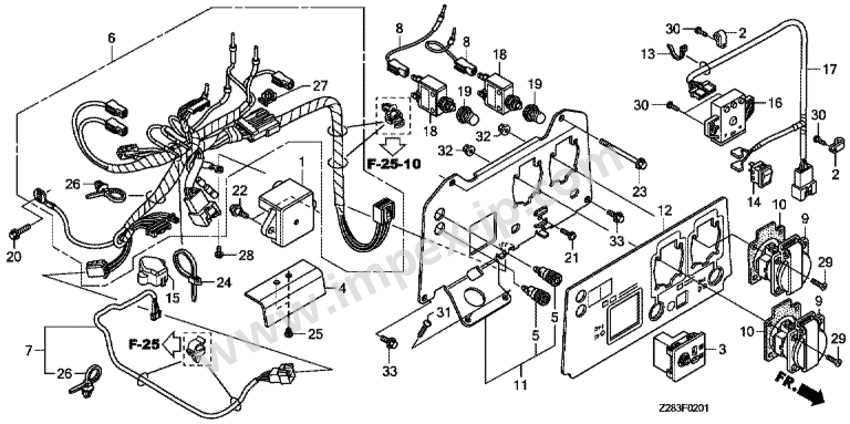

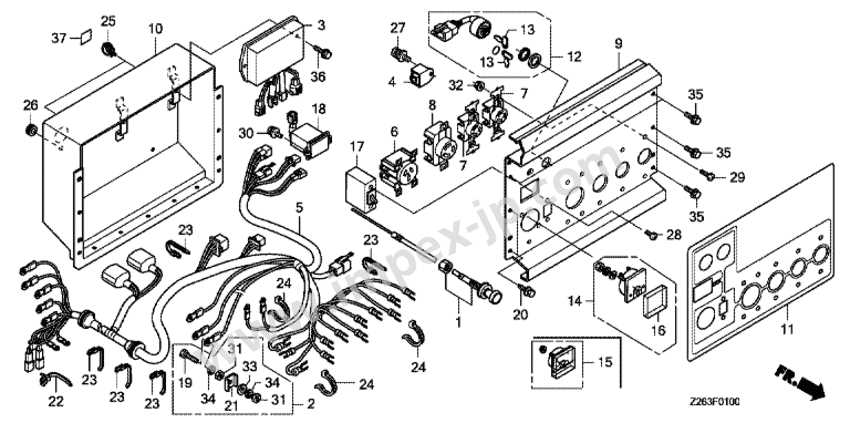

Understanding the Generator Component Layout

Every power-generating machine is built with a specific arrangement of elements that work together to ensure smooth operation. Familiarizing yourself with the layout of these key sections is essential for effective maintenance and troubleshooting. By recognizing the positioning and function of each unit, you’ll be better equipped to identify issues and perform necessary repairs when needed.

Main Sections of the Generator

The machine consists of several distinct areas, each dedicated to specific tasks such as energy conversion, cooling, and control. These regions are interrelated and designed to optimize efficiency. A clear understanding of how each component fits into the larger structure helps users quickly locate and address problems.

Key Functions of the Layout

The strategic placement of parts within the generator plays a significant role in its functionality. From fuel intake to exhaust management, every component is positioned to maximize performance and safety. Knowing where each piece resides ensures that users can easily inspect, replace, or clean them, helping to maintain optimal performance over time.

How to Identify Key Components in the Layout

Recognizing the essential elements of a machine’s layout is a crucial skill when performing maintenance or repairs. By focusing on the major components, users can quickly understand their function and role within the system. Familiarity with the placement and purpose of each part enables more effective troubleshooting and faster resolution of issues.

To identify key components, start by reviewing the labels and numbering often found next to each section. These markings provide valuable clues to the function and relationship between different parts. Additionally, understanding the flow of energy, air, and fuel through the system can help pinpoint where specific elements are located and how they contribute to the overall operation.

Once you’re able to recognize these core units, it becomes easier to track down potential issues and ensure the smooth functioning of the equipment. This knowledge allows for better preparation and efficiency in both routine maintenance and emergency repairs.

Common Issues and Solutions for Generator Components

Generators, like all mechanical devices, can experience a range of issues related to their individual components. Knowing the most common problems and their corresponding solutions can help users address failures quickly and maintain the longevity of their equipment. By being familiar with potential faults, you’ll be able to troubleshoot more effectively and avoid unnecessary downtime.

One frequent issue is the failure of the fuel system, which can result from clogged filters or blocked fuel lines. Cleaning or replacing these elements often restores proper functionality. Another common problem involves the ignition system, where faulty spark plugs or loose connections can cause starting difficulties. Regular inspections and maintenance of the ignition system are essential to prevent these issues.

Additionally, improper cooling can lead to overheating and engine damage. Ensuring that air vents and cooling fans are free of debris can prevent this issue. Addressing these common problems promptly will help your equipment run efficiently and reduce the risk of costly repairs.