Proper maintenance of your lawn equipment is essential for ensuring long-lasting performance and efficiency. A solid understanding of its individual components allows for smoother repairs and better care over time. Knowing how different parts work together can help you troubleshoot issues and replace broken elements with ease.

Each machine is made up of various parts, each serving a specific purpose to keep the tool operating smoothly. By familiarizing yourself with these components, you can quickly identify worn-out or damaged parts that may need attention. Having access to a clear breakdown of the assembly makes it easier to maintain your equipment and avoid costly repairs.

In this guide, we will explore the key elements that make up your tool, focusing on how to identify, maintain, and replace parts when needed. With this knowledge, you can ensure your machine remains in top shape, extending its lifespan and enhancing its performance.

Understanding the Lawn Tool Components

Every landscaping tool is composed of various elements that work together to ensure smooth operation and efficiency. Knowing how these individual components function will help you troubleshoot problems, perform necessary maintenance, and replace any faulty pieces when required. A solid understanding of these parts also enables you to keep your machine in good working condition for years to come.

Key Components and Their Functions

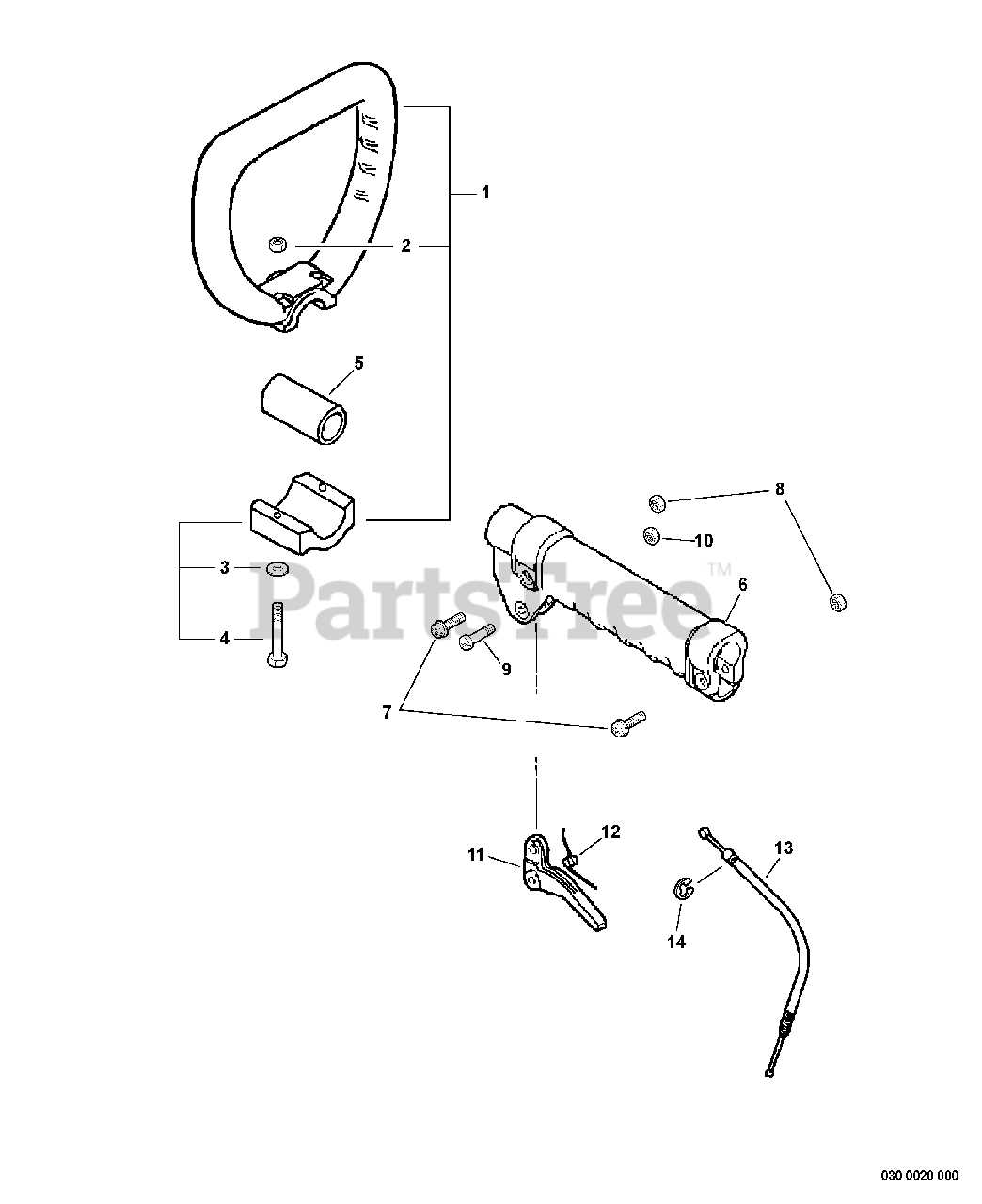

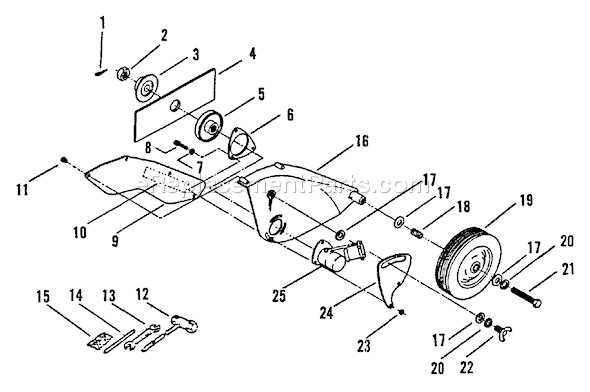

Machines like these typically include a motor, blade, and handle, each serving a crucial role. The motor provides the power needed to operate the device, while the blade is responsible for cutting through tough grass and soil. The handle, on the other hand, provides the user with control and maneuverability. Additionally, there are smaller elements such as bolts, springs, and guides that ensure everything stays in place and functions as it should.

Maintaining and Replacing Worn-Out Parts

After consistent use, certain components may begin to wear out. This can lead to diminished performance or even breakdowns. It’s important to regularly check for signs of wear, such as dull blades, loose screws, or worn-out gears. Knowing where to find replacement parts and understanding how to install them will save both time and money in the long run, helping you keep your equipment in top shape.

How to Identify Lawn Tool Components

Recognizing the various components of your landscaping equipment is essential for proper maintenance and repair. Being able to quickly identify each part allows you to address issues effectively and ensures that your machine operates efficiently. The following steps will guide you in distinguishing and understanding the different elements that make up your tool.

- Motor: The heart of the machine, providing the necessary power for operation.

- Blade: The cutting element that performs the core function of trimming grass and soil.

- Handle: The part you grip to control and maneuver the tool during use.

- Gearbox: The mechanism that transfers power from the motor to the blade.

- Throttle: The control for regulating the speed of the motor.

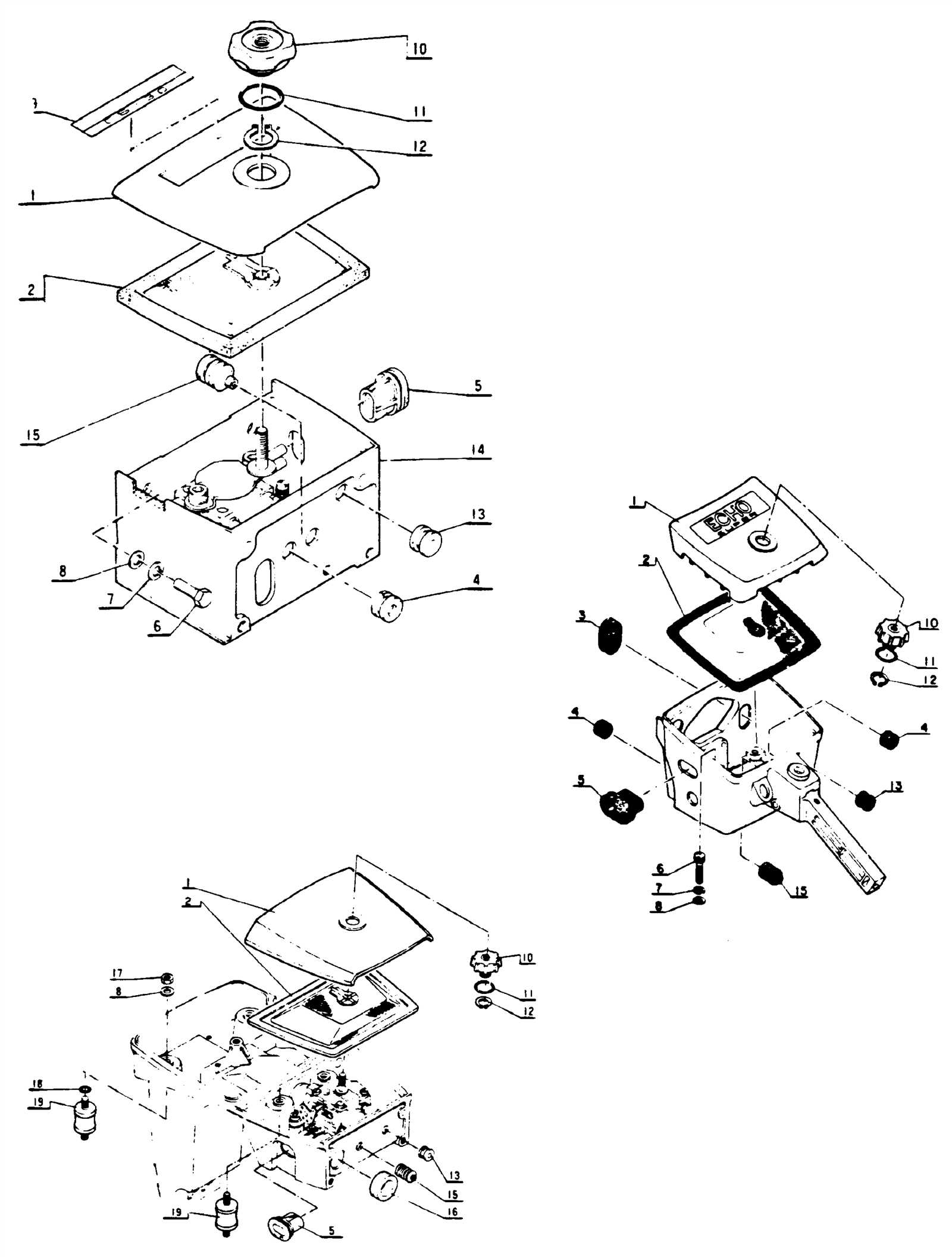

- Fuel System: Includes the tank, fuel lines, and filter, responsible for supplying the engine with fuel.

In addition to the main components, you may also find smaller, but equally important, parts like fasteners, springs, and guides that help secure and align the larger elements. To properly identify them, consult the tool’s user manual or a detailed component chart, which will provide clear visual references and descriptions for each piece.

Common Lawn Tool Replacement Parts

Over time, certain components of your landscaping tool may wear out or become damaged due to frequent use. Understanding which elements commonly need replacement will help you keep your equipment running smoothly. Regular maintenance and timely replacements are key to extending the lifespan of your machine and maintaining its performance.

Frequently Replaced Components

Several key components are more likely to require replacement as the tool ages or experiences heavy use:

- Blades: The cutting elements are exposed to constant friction and impact, making them prone to dulling or chipping.

- Air Filter: A clogged air filter can affect engine performance, leading to reduced power or difficulty starting the machine.

- Fuel Lines: Over time, fuel lines can crack or become brittle, causing leaks or engine performance issues.

- Drive Belt: The drive belt is responsible for transferring power to the blade and may wear down or snap with extended use.

How to Replace Worn-Out Parts

To replace any worn or damaged components, refer to the user manual for instructions specific to your tool. Always ensure you’re using high-quality replacement parts designed for your machine to maintain optimal performance. When replacing critical components like the blade or air filter, take care to install them correctly to avoid further damage or malfunction.