When it comes to maintaining your equipment, having a clear understanding of its individual components is essential for efficient repairs and troubleshooting. Identifying and managing the various pieces that make up your tool ensures longevity and proper functionality.

By learning how to interpret the visual representation of these elements, you can quickly identify issues and make necessary adjustments or replacements. This knowledge empowers you to carry out basic repairs with confidence and avoid unnecessary delays.

Familiarity with common failures and wear patterns allows for preventative measures, saving you time and money. This guide will walk you through the crucial components and offer practical insights into keeping your equipment in top condition.

Understanding the Husqvarna 142 Parts

Every piece of equipment is made up of multiple components that work together to ensure optimal performance. Understanding how these individual elements interact can help users troubleshoot problems more effectively and perform necessary repairs. Knowing the role of each part and its function allows for informed decision-making when it comes to maintaining and replacing worn-out pieces.

Common tools, especially power-driven ones, rely on precise mechanical systems. These systems are composed of various components such as fasteners, engine elements, and safety features. Familiarizing yourself with the layout and purpose of these components is key to ensuring the device continues to run smoothly.

By identifying the specific elements and understanding their wear and tear patterns, users can prevent potential breakdowns and extend the life of the tool. Whether for routine maintenance or unexpected repairs, knowledge of these pieces provides a solid foundation for efficient management and operation.

How to Read the Husqvarna 142 Diagram

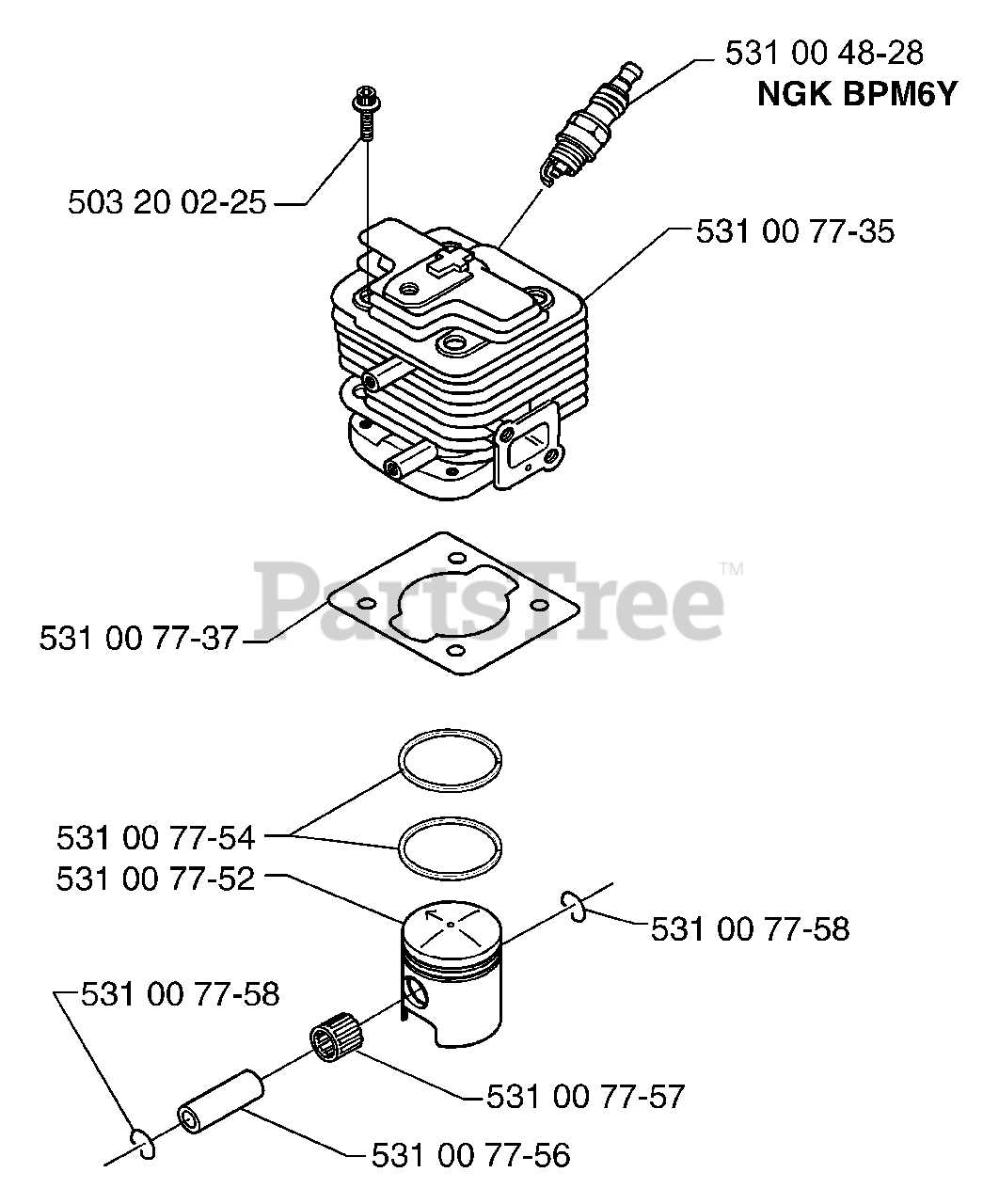

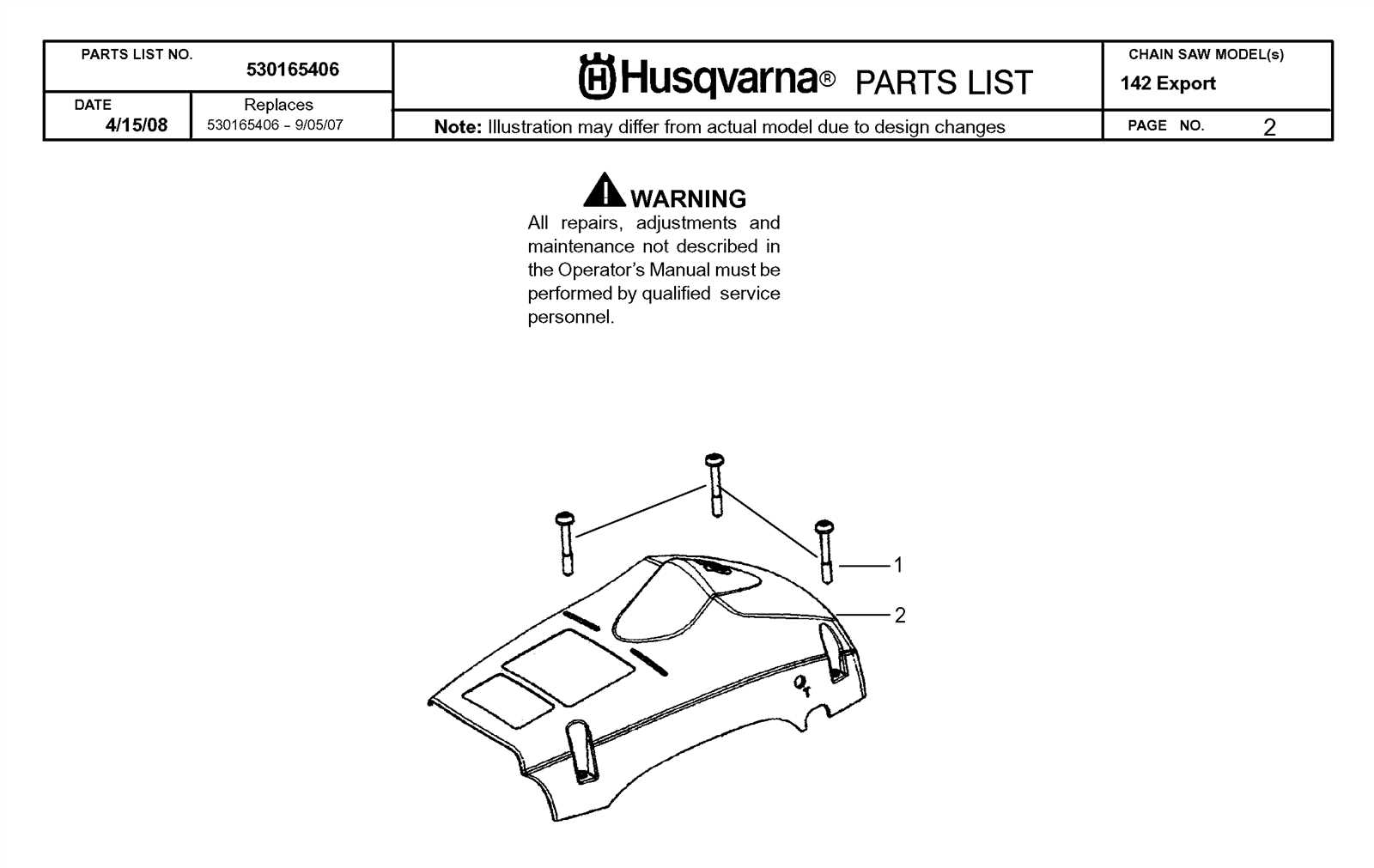

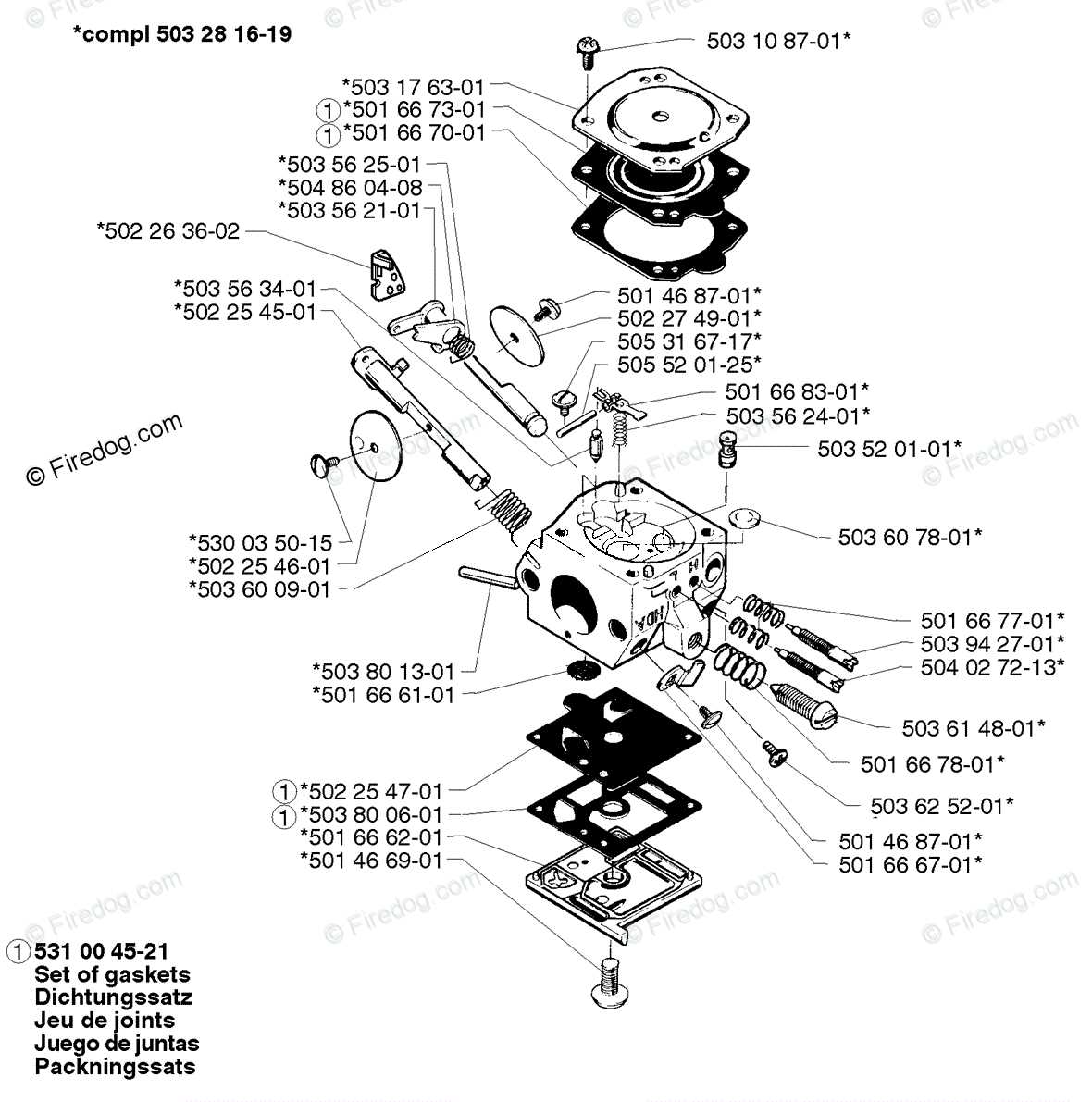

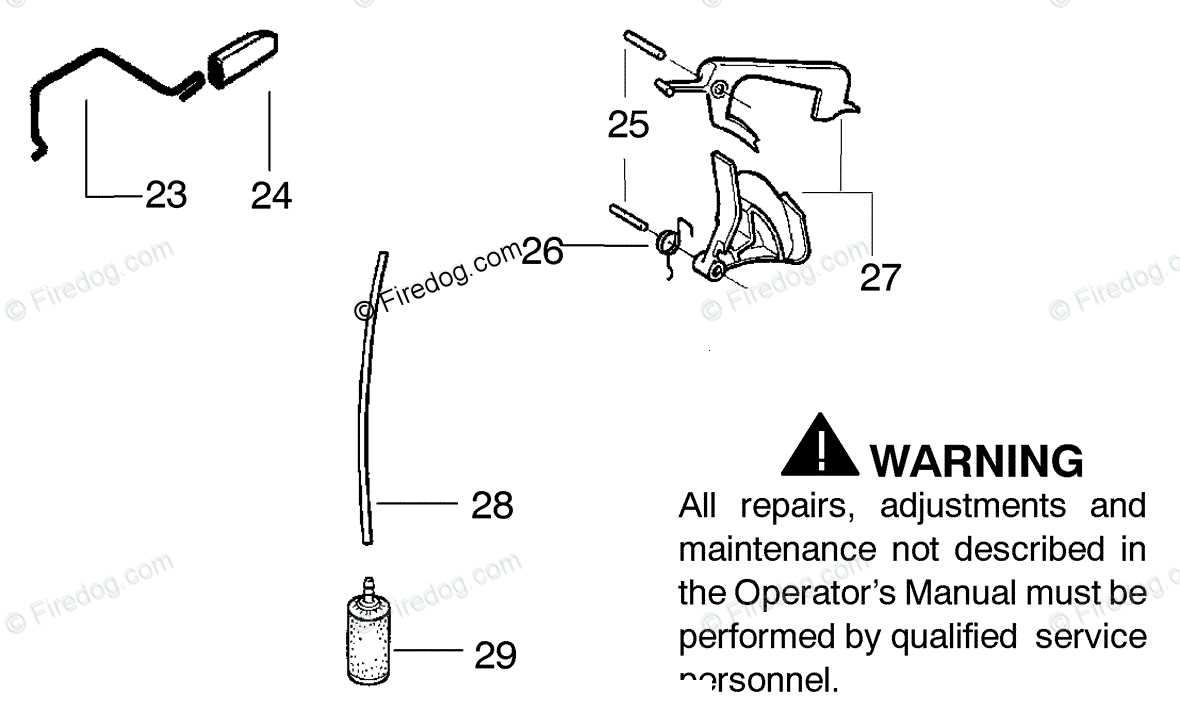

Being able to interpret a visual representation of your tool’s components is essential for any repair or maintenance task. These illustrations provide a clear overview of how the various elements fit together, making it easier to identify each part’s function and position within the system.

To begin, focus on the labeled sections and the connections between different components. Most diagrams use numbers or letters to identify specific pieces, so you can cross-reference them with a parts list for accurate identification. Pay attention to any arrows or markings that indicate movement or assembly instructions.

Understanding the flow of the diagram is crucial. It’s common for a diagram to be organized in a way that shows the assembly process from top to bottom or left to right. Each group of parts may be displayed individually, showing their relative positions and interactions with other elements. This helps you visualize the tool’s internal structure, making repairs or replacements easier to execute.

Familiarizing yourself with the layout of these visual aids will help you make quick and informed decisions, ensuring that maintenance tasks are completed without unnecessary complications.

Common Repairs with Husqvarna 142 Parts

Over time, every tool will encounter wear and tear, and knowing how to address common issues can help maintain its performance. Certain repairs are often needed more frequently due to the heavy use of specific components, which can lead to mechanical failure or decreased efficiency.

Some of the most common repairs include:

- Engine maintenance: Regularly checking and replacing spark plugs, air filters, and fuel lines ensures that the engine runs smoothly and starts with ease.

- Chain tension adjustments: Over time, the chain may become loose or worn out, requiring adjustments or replacements to maintain cutting efficiency.

- Clutch system repairs: The clutch often faces stress from regular use, leading to the need for periodic inspection and possible replacement of worn-out parts.

- Bar and chain lubrication: Insufficient lubrication can lead to faster wear of both the bar and the chain, requiring the periodic replacement of these components to avoid damage.

By understanding these frequent repair needs and knowing how to perform them, users can keep their equipment in optimal condition. Addressing these issues early helps prevent more serious problems down the road, ensuring the longevity of the tool.