Proper maintenance is essential to keep your lawn mower running smoothly and efficiently. Understanding the layout and components of the machine can help you identify potential issues and perform necessary repairs with confidence. This section will guide you through key aspects of mower upkeep, focusing on visual aids to assist with part identification and troubleshooting.

Whether you are a seasoned gardener or a new mower owner, knowing how to navigate the intricate systems within your machine can save you time and money. Accurate part identification is crucial when addressing wear and tear or replacing broken elements. By following detailed visuals, you can ensure a better understanding of your equipment and improve its performance over time.

Understanding Lawn Mower Components

Maintaining a lawn mower requires a solid understanding of its individual components. Each part plays a critical role in the overall function and performance of the machine. Recognizing how these elements work together can help you identify issues early and ensure efficient operation for years to come.

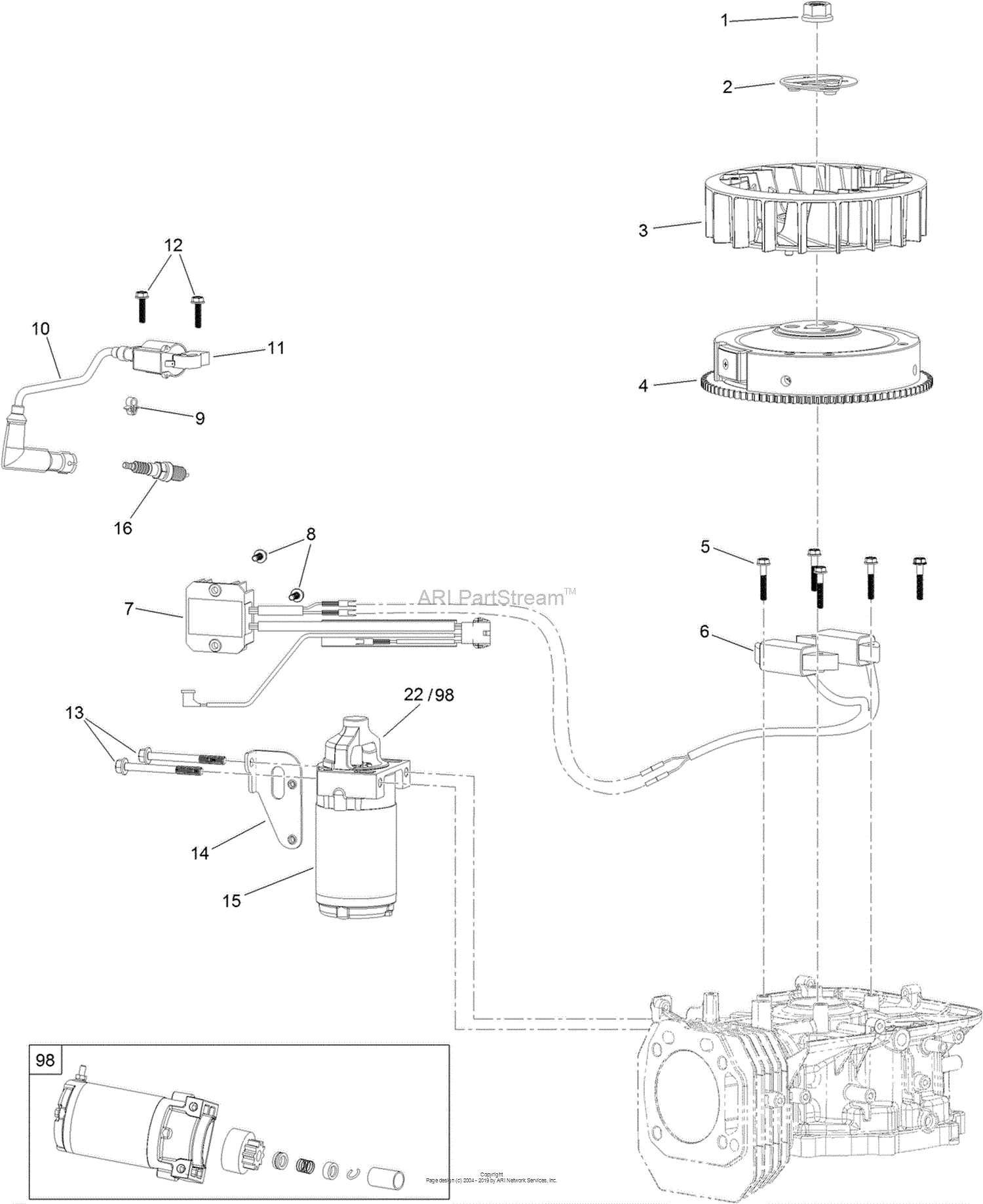

The engine, cutting system, and transmission are just a few of the key areas you should familiarize yourself with. By learning the placement and function of each component, you can diagnose problems faster and make the right decisions when it’s time for repairs or replacements. Clear visual representations are often the most effective way to understand the arrangement and interactions of these systems.

Effective troubleshooting becomes much easier when you have a solid grasp of how the machine is built. Each part is connected, and knowing how they fit together will allow you to handle maintenance tasks confidently and with precision. This section will help break down the essential components, so you can perform the necessary upkeep without hesitation.

How to Identify Key Components on the Visual Guide

Understanding the visual layout of your equipment is a crucial skill for any owner or technician. By analyzing the different sections of a machine, you can easily pinpoint the most important components and their locations. This knowledge simplifies the process of maintenance and troubleshooting.

Each section of the guide typically features a clear depiction of the individual elements and how they are arranged. It is important to familiarize yourself with common symbols or labels that help identify specific parts. Look for easily recognizable features such as the engine, wheels, and blades, as these are often the most crucial areas to check when diagnosing issues.

Once you’ve identified the key components, it becomes much easier to assess whether something needs replacing or repair. Pay attention to the way parts are connected, as this will help you understand their relationship to one another. Familiarity with the guide’s structure will allow for a more efficient maintenance process and a deeper understanding of how your machine operates.

Steps to Replace Key Components

Replacing damaged or worn-out components of your lawn equipment is a straightforward process when you follow the right steps. First, ensure that the machine is powered off and disconnected from any power source to avoid accidents. It’s crucial to have the necessary tools on hand, such as wrenches, screwdrivers, and replacement items.

Start by identifying the exact part that needs to be replaced. Refer to the visual guide or user manual to locate the damaged component. Once located, carefully remove any screws, bolts, or clips securing the part in place. Keep track of all fasteners to make reassembly easier.

After removing the faulty part, position the new component correctly. Ensure it aligns with the connections and fastens securely. Tighten the bolts and screws, but avoid over-tightening, as this could damage the part or surrounding components. Finally, check the machine’s functionality by performing a test run to ensure everything is operating smoothly.