Maintaining and repairing outdoor power equipment requires a clear understanding of its individual elements. Each tool is made up of a variety of components that work together to ensure optimal performance. Knowing how to identify and replace these elements is essential for effective upkeep.

Exploring these parts involves studying how each piece fits within the machine’s overall structure. Understanding the layout helps to avoid unnecessary confusion when diagnosing issues or performing routine maintenance tasks.

By familiarizing yourself with a detailed illustration of the tool’s components, you’ll be able to make informed decisions about repairs or replacements. This knowledge can save time and ensure your equipment operates efficiently for years to come.

Understanding Chainsaw Component Breakdown

When maintaining a chainsaw, it’s essential to have a clear understanding of its internal structure. Each tool consists of several key elements that perform specific functions, all working together to keep the equipment running smoothly. Being able to identify these components and their relationships can significantly ease the process of repairs and regular maintenance.

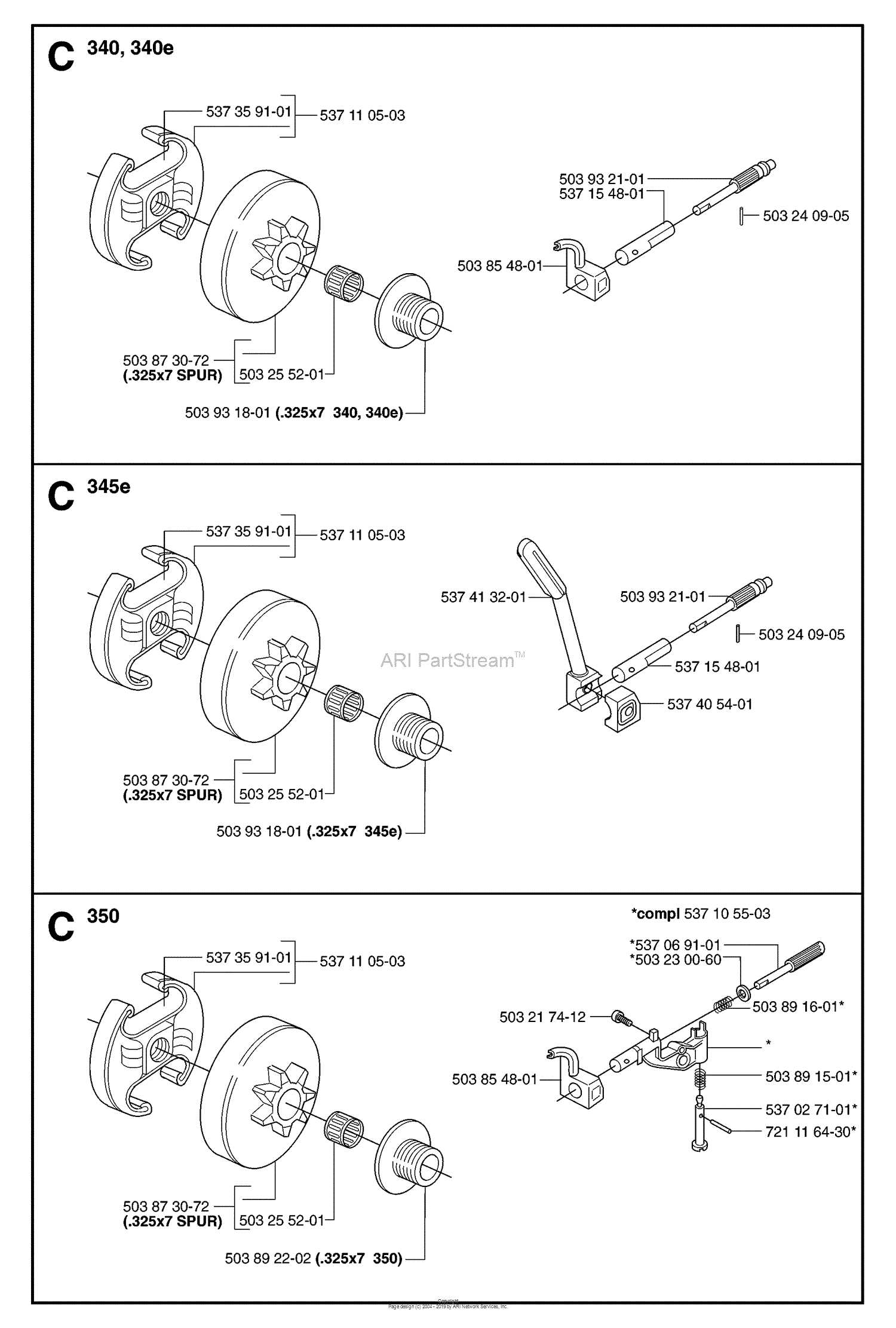

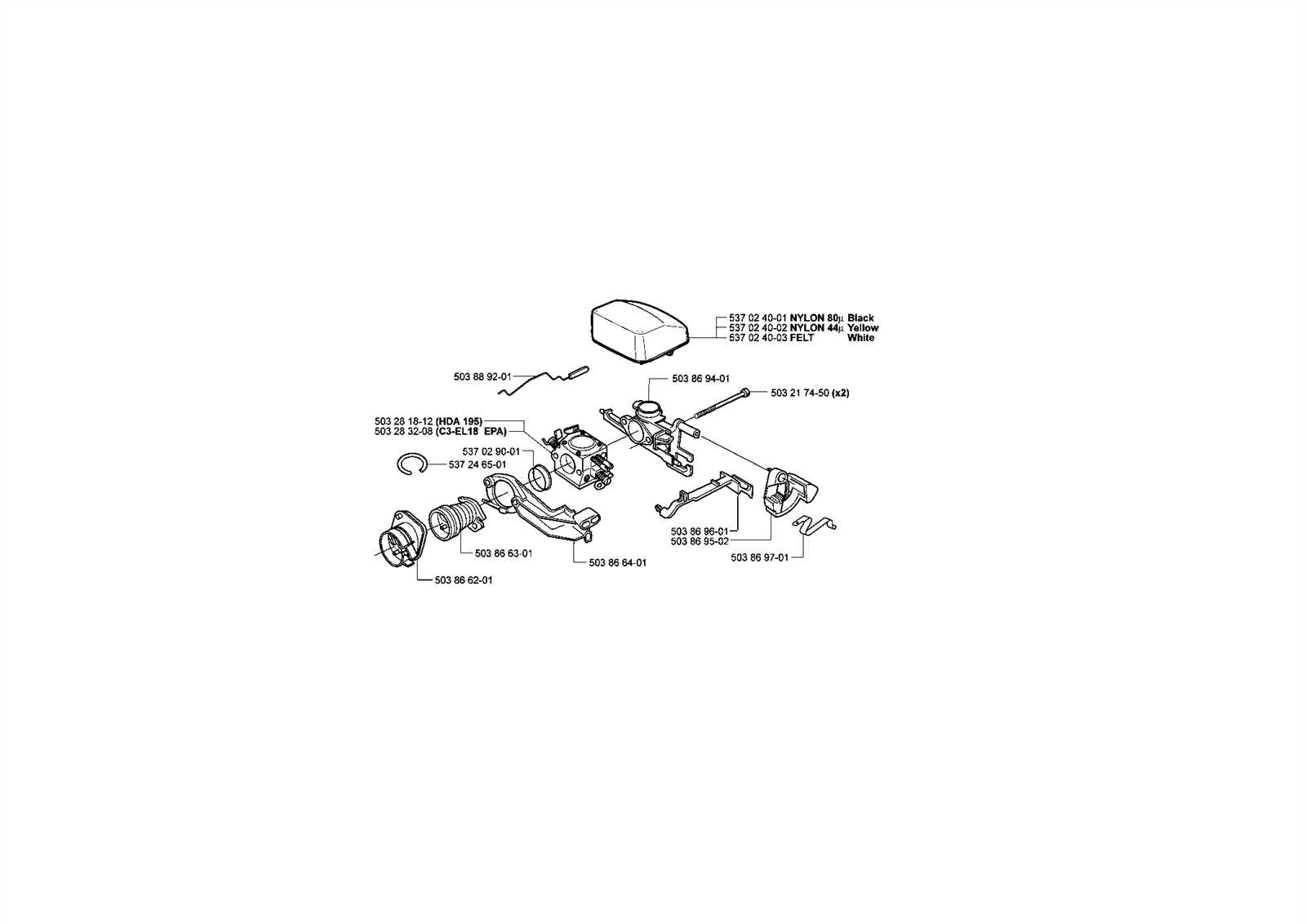

Reading and Interpreting the Illustration

A detailed visual representation of a chainsaw’s components serves as a useful guide for recognizing where each piece fits into the overall design. It can help in identifying specific areas that may need attention, whether for cleaning, repair, or replacement. Each part is numbered or labeled for easy reference, simplifying the maintenance process.

Identifying Common Issues

With a clear understanding of the layout, it becomes easier to diagnose common problems. Whether it’s a malfunctioning engine or a damaged blade, knowing where to look and what each part does allows you to troubleshoot effectively. A comprehensive breakdown also helps in determining which components need replacing and ensures the correct parts are sourced.

How to Read the Chainsaw Component Breakdown

Understanding a visual representation of a chainsaw’s inner workings is crucial for effective maintenance. These illustrations provide a clear guide to where each part fits and how they interact within the machine. By familiarizing yourself with the layout, you can more easily identify components and spot potential issues that require attention.

Start with the legend or key–most diagrams include a numbered list or references that correspond to each labeled part. This will help you identify the function and location of individual components, allowing for a more precise approach to maintenance.

Pay attention to the connections between parts, as these links often indicate how components work together. For example, a line connecting the carburetor to the engine highlights their interdependence. Recognizing these relationships is vital for troubleshooting and ensuring that all parts are properly assembled.

Common Chainsaw Components and Functions

Each chainsaw contains a variety of essential components that contribute to its overall performance. Understanding the role of each part ensures that users can properly maintain and repair their equipment. Some parts play a crucial role in starting the engine, while others focus on controlling the cutting action or enhancing safety during operation.

Engine and Fuel System

The engine is the heart of any chainsaw, driving the power that propels the chain. The fuel system, including the carburetor and fuel lines, ensures that the engine receives the necessary mixture of fuel and air for combustion. Regular inspection of these components is important for maintaining efficiency and preventing engine failure.

Cutting Mechanism and Safety Features

The cutting system consists of the guide bar and chain, which work together to cut through wood. The chain must be regularly sharpened to maintain its cutting ability. Safety features, such as the brake and throttle lock, are designed to prevent accidents and ensure user protection while operating the chainsaw.