Exploring the key components that make up complex machinery is essential for proper maintenance and efficient performance. By examining the different elements that work together, users can gain a clearer understanding of how each part contributes to the tool’s functionality.

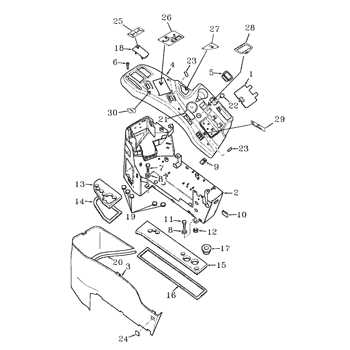

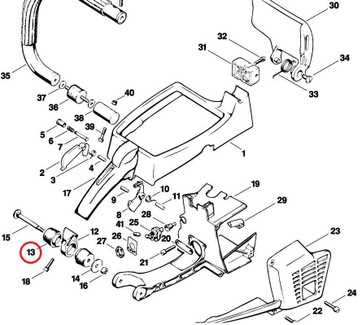

Accurate identification of each individual component allows for easier troubleshooting and repair, ensuring that the tool runs smoothly for years. This breakdown offers a visual reference that helps with recognizing each essential element, making the maintenance process less daunting for both new and experienced users alike.

Understanding the Components of the Power Tool

Proper knowledge of the internal structure of a power tool is vital for efficient use and long-term durability. Each mechanism plays a specific role, and recognizing these elements can significantly enhance the user’s ability to maintain and repair the tool when necessary. A thorough understanding helps in identifying potential issues and addressing them promptly.

Breaking down the assembly into its individual units allows for easier access to each piece. This systematic approach ensures that every part, from the engine to the housing, functions optimally. Regular inspections of these components can prevent unexpected breakdowns, leading to a longer life for the equipment.

How to Read the Power Tool Assembly Guide

Understanding how to interpret a visual reference of a tool’s internal layout is crucial for efficient repairs and maintenance. These guides provide a clear representation of how various components are interconnected, allowing users to locate and identify each piece quickly. The proper approach ensures that users can follow along step by step during the disassembly or assembly process.

Familiarizing yourself with the symbols and labels used in the illustration is key. Each component is typically numbered or marked for easy identification, with lines indicating how different parts are connected. This structured presentation simplifies the task of pinpointing which sections may require attention or replacement, reducing the likelihood of errors.

Identifying Common Components in the Power Tool

Recognizing the key elements that make up a power tool is essential for understanding its operation and maintenance. Each component, though distinct, works in harmony with others to ensure the tool functions properly. Knowing the typical elements you will encounter during a breakdown is crucial for efficient repairs and replacements.

Familiarizing yourself with the most common components, such as the engine, carburetor, and housing, provides a solid foundation for any repair work. These primary units are usually the first to require attention, either due to wear or performance issues. Understanding how they interact can help you quickly diagnose problems and proceed with necessary adjustments or replacements.