When it comes to maintaining and repairing outdoor equipment, understanding the internal components is crucial for effective operation and longevity. The right tools and knowledge of each element can save time and reduce repair costs. This section provides a comprehensive guide to identifying and working with the essential parts of your machinery.

Every machine is built with a variety of interconnected components, each serving a unique function. By learning about these parts, you can troubleshoot issues more efficiently and ensure that each piece is properly maintained. Whether you are replacing a worn-out part or performing regular maintenance, knowing how to navigate through the assembly will enhance your overall experience.

Accurate identification of each part is essential for ensuring compatibility and smooth operation. This guide will walk you through the process of understanding how to read and interpret the layouts, allowing you to handle repairs and upgrades with confidence.

Overview of Husqvarna 359 Parts

Understanding the internal makeup of any machinery is essential for proper maintenance and repair. The system of interconnected components ensures the machine functions smoothly and efficiently. Recognizing each element’s role is the first step in ensuring long-term reliability and performance.

Key components typically include mechanical, electrical, and fuel-related elements that work together to keep the equipment running. From the power transmission system to the control mechanisms, each piece is vital for overall functionality. Learning how these elements interact can help you avoid common issues and identify malfunctions early.

Maintenance and repairs become much simpler when you are familiar with the basic structure and functions of the internal components. Being able to identify each part helps ensure compatibility during replacements, reduces errors, and contributes to smoother troubleshooting procedures.

How to Read the Parts Diagram

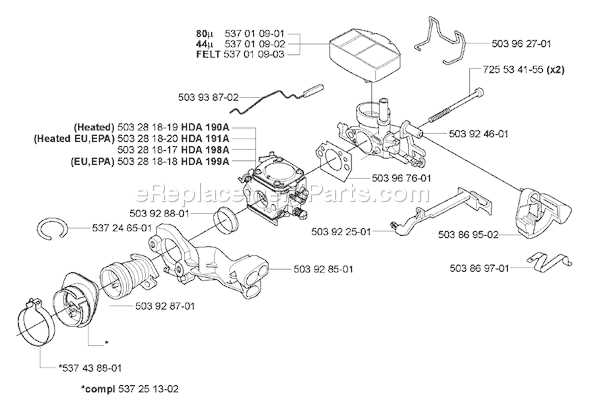

Reading the layout of machine components can seem daunting at first, but once you understand the basic structure and conventions used, the process becomes intuitive. Each element is labeled and arranged in a way that visually demonstrates how they interact within the system. The goal is to quickly identify which parts are involved in a specific repair or upgrade.

Understanding the Labels

The labels on the chart provide key information about each part, such as its identification number, name, and sometimes additional details like material or specifications. It’s important to familiarize yourself with these codes, as they allow you to easily cross-reference with the machine’s manual or inventory system. A strong grasp of these terms ensures smoother repairs and replacement procedures.

Following the Visual Flow

In many layouts, parts are shown in their relative positions, creating a flow that mirrors their physical arrangement in the machine. By following this visual guide, you can understand how components are connected and their role in the overall system. It’s essential to pay attention to the direction of the flow, which often indicates the sequence of assembly or disassembly.

Clear visualization and understanding of how to interpret these diagrams will significantly improve your ability to perform repairs and maintenance tasks. This knowledge empowers you to work efficiently and accurately, ensuring the longevity and reliability of your equipment.

Common Issues and Parts Replacement

Over time, certain components of outdoor machinery may wear out or fail due to constant use or environmental factors. Recognizing these issues early and replacing the faulty parts can help maintain optimal performance. Regular inspections are crucial for identifying potential problems before they escalate into more costly repairs.

One of the most common problems is engine misfiring, which can occur due to worn-out spark plugs or fuel system clogs. Another frequent issue is the failure of the fuel pump, often caused by debris or age, leading to inefficient fuel delivery. Both of these issues can significantly affect the operation, making timely replacement essential.

Worn-out chains or belts are also common in machinery subjected to high torque and constant motion. These components must be checked periodically and replaced if they show signs of excessive wear, such as fraying or stretching. Regular maintenance of these elements ensures the equipment functions properly and reduces the risk of sudden failures during operation.